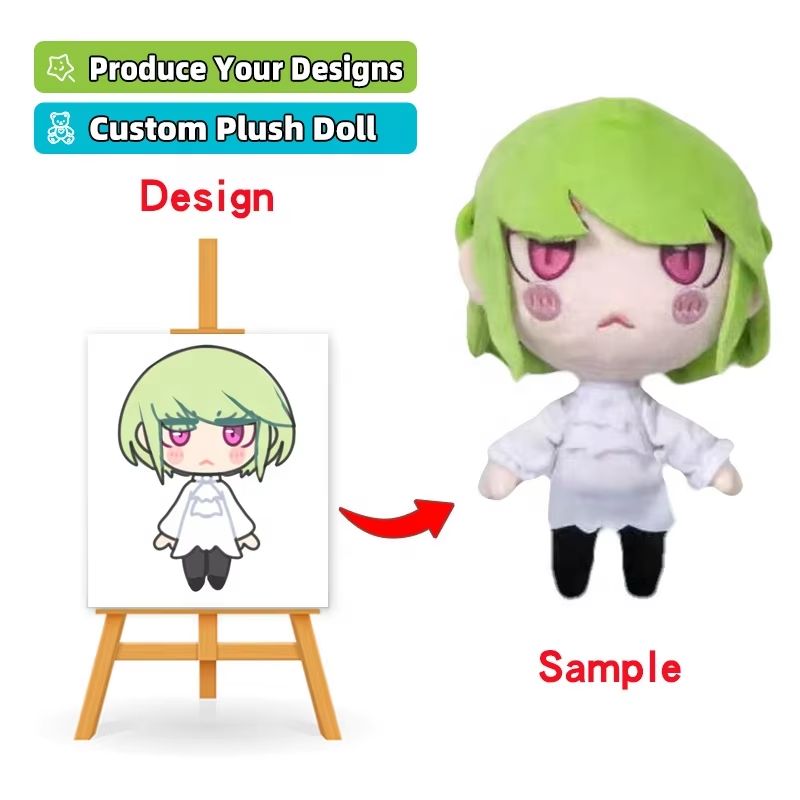

ספקית חיות פלש מותאמת אישית

ספק חיות פליש מותאם אישית משמש כשותף ייצור מתמחה הממיר רעיונות יצירתיים לחיות צמר גס איכותיות ומותאמות לפי דרישות ספציפיות. ספקים אלו מפעילים מתקני ייצור מתקדמים מצוידים במכונות טקסטיל מתקדמות, מערכות רקמה ממוחשבות וציוד חיתוך מדויק כדי לספק מוצרים אישיים מפליש. הפונקציה העיקרית כוללת שיתוף פעולה עם עסקים, ארגונים ואנשים פרטיים כדי ליצור חיות פליש ייחודיות שמשקפות את זהות המותג, קורכות אירועי עצר והזכרון או ממלאות מטרות שיווקיות. ספקי חיות פליש מותאמות תומכים באוספים נרחבים של בד כולל מגוון רחב של kếtש, צבעים וחומרים, החל מקוטן ופוליאסטרتقليדיים ועד לחומרים אורגניים פרימיום ואפשרויות היפות allergenic. היכולות הטכנולוגיות שלהם כוללות תוכנות עיצוב דיגיטלי המאפשרות ללקוחות לדמיין דמויות מוקדמות לפני הייצור, ומבטיחות הצגה מדויקת של הדרכים הרצויות. תהליכי הייצור כוללים מדדי בקרת איכות במספר שלבים, החל מיצירת התבניות הראשונית ועד האריזה הסופית. ספקים אלו מציעים בדרך כלל שירותים מקיפים הכוללים פיתוח רעיונות, ייעוץ טכני, יצירת דמויות מוקדמות, ייצור בהיקף גדול ותיאום לוגיסטיקה. השימושים משתרעים על פני תחומים תעשייתיים שונים כגון קמעונאות, סמן קורפורטיבי, מוסדות חינוכיים, מתקני בריאות, חברות בידור וארגונים לא ממשלתיים. מחלקות חינוכיות משתמשות בחיות פליש מותאמות בתור מחזות, כלים לימודים ופריטי גיוס כספים, בעוד שסופרי שירותי בריאות משתמשים בחיות צמר גס טיפוליים להנחתת החולים וצמצום 스טראס. תעשיית הבידור מנצלת ספקים אלו לשיווק דמויות, קידום סרטים ולעזרי משחקים. לקוחות עסקיים מבקשים לעיתים קרובות חיות פליש מותאמות למתנות בירידים מקצועיים, תוכניות הכרת תודה לעובדים וمبצעי נאמנות ללקוחות. מומחיות הספק משתרעת גם להתאמה לנורמטיבים, ומבטיחה שהמוצרים עומדים בדרישות הבטיחות הבינלאומיות, כולל סימון CE, התקנות CPSIA וمواصفות ASTM. ספקים מתקדמים מציעים גם אפשרויות ייצור בר-קיימה, הכוללות שימוש בחומרים מחזוריים ושיטות ייצור ידידותיות לסביבה כדי להתמודד עם דאגות סביבתיות תוך שמירה על סטנדרטים של איכות ועמידות המוצר.