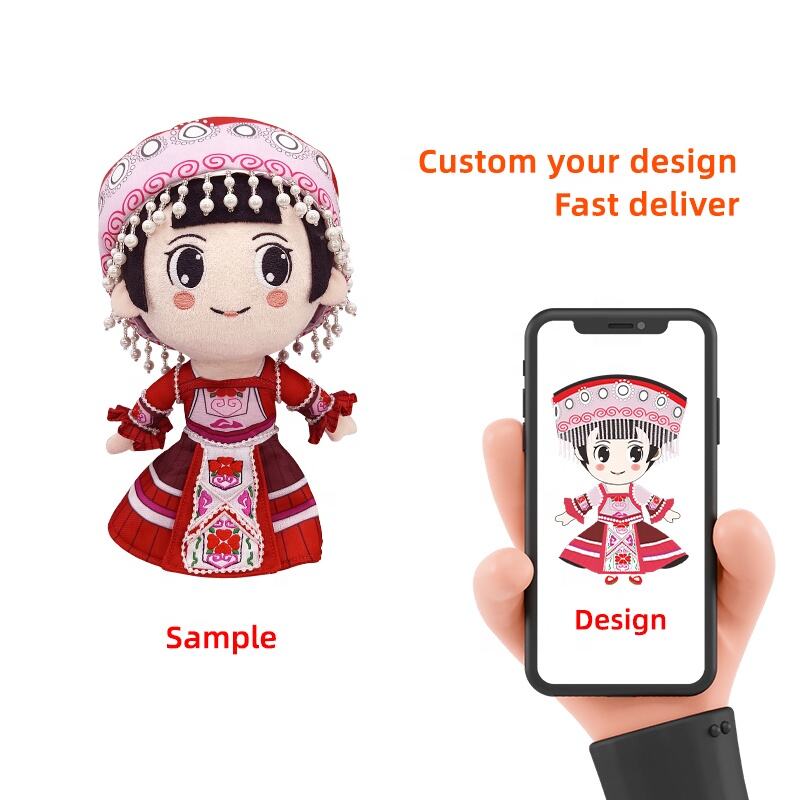

יצרן חיות ממולא מותאמות אישית

יצרן בובות צמר מותאמות למשתמש פועל כמתקן ייצור מתקדם הממיר רעיונות יצירתיים לבובות צמר מוחשיות ומותאמות אישית. מתקני הייצור האלה פועלים באמצעות מערכות ייצור מתקדמות המשלבות אומנות מסורתית עם טכנולוגיה מודרנית, כדי ליצור בובות צמר ייחודיות המותאמות לדרישות ספציפיות. התפקיד המרכזי של יצרן בובות צמר מותאמות למשתמש כולל תכנון, פיתוח דגמי ניסוי ורישוי ייצור המוני של צעצועי צמר לפי דרישות הלקוח, בין אם עבור לקוחות פרטיים, עסקים או קמפיינים שיווקיים. התשתית הטכנולוגית של יצרנים אלה כוללת בדרך כלל תוכנות לעיצוב בעזרת מחשב, מכונות חיתוך מדויקות, ציוד תפירה תעשייתי ומערכות בקרת איכות המבטיחות תקנים עקביים בייצור. יצרנים מתקדמים משתמשים בטכנולוגיית דימות תלת-ממד כדי לדמיין עיצובים לפני תחילת הייצור, ומאפשרים ללקוחות להציג מראש את היצירות המותאמות שלהם ולערוך התאמות נדרשות. תהליך הייצור כולל בחירת חומרים, יצירת תבניות, חיתוך, תפירה, מילוי, שלבים של גימור ובדיקות איכות. מתקני ייצור מודרניים של בובות צמר מותאמות למשתמש לרוב כוללים מערכות אוטומטיות לביצוע משימות חוזרות, תוך שמירה על אלמנטים של יד ערה לצורך פרטים מורכבים. היצרנים עובדים עם מגוון חומרים, ביניהם בדידים איכותיים, חומרי מילוי היפותלרגניים, רכיבים שעברו בדיקות בטיחות, וכלי ציוד מיוחדים. היישומים משתרעים על פני מגזרים ותכליתים רבים, החל ממונטראים של חברות וסחורה שיווקית, דרך חברות טיפוליות למוסדות בריאות, כלים חינוכיים לבתי ספר, זיכרונות לבעלי חיים שנספו, ועד מתנות מותאמות לרגעים מיוחדים. היכולת להסתגל של יצרן בובות צמר מותאמות למשתמש מאפשרת לו לעמוד בדרישות פרויקטים שמתפרסים מפיתוח דגם ניסיון בודד ועד ריצות ייצור מסחריות בקנה מידה גדול, מה שהופך אותם לשותפים חיוניים לעסקים המחפשים סחורה מותאמת למותג או לאנשים פרטיים המעוניינים בחפצים ייחודיים לזכרון.