Нэвтрэх боломжтой Захиалгат Опцинууд ба Масштаблах Үйлдвэрлэлийн Чадавх

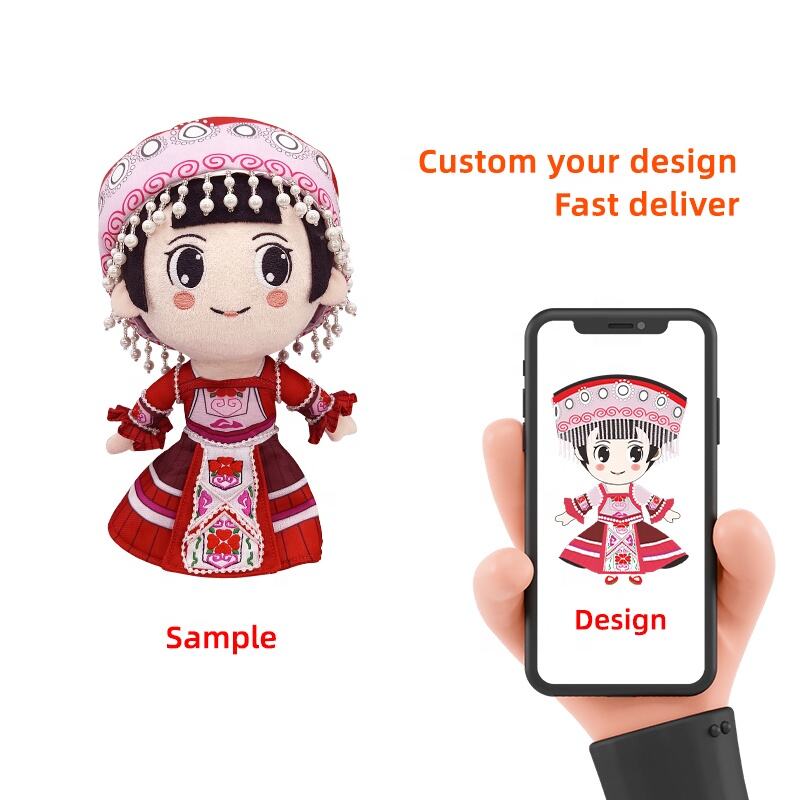

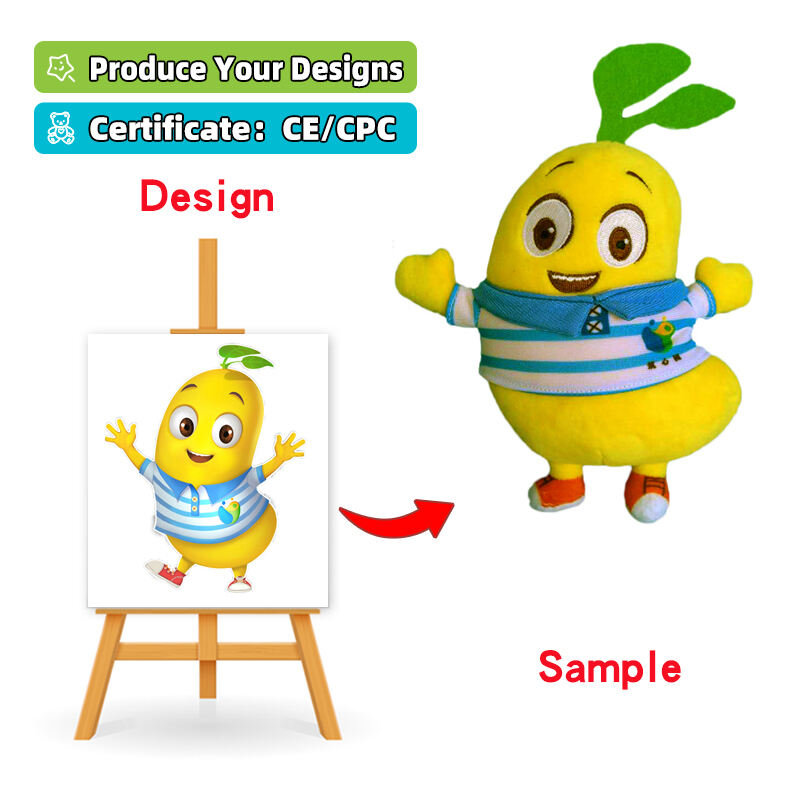

Онцгой захидалтын цугаалга тоглоомны үйлдвэрийн гол онцлог нь төсөл бүрийн хэмжээ, нарийн төвөгтэй байдлаас үл хамааран масштаблагдах үйлдвэрлэлийн чадавхийг хадгалж, олон талын захидалтын шаардлагыг хангах чадвар юм. Энэ уян хатан байдал нь туршлагатай мэргэжилтнүүд өөрсдийн захидалт цугаалга тоглоомны тодорхой шаардлага, зориулалтын хэрэглэгчдийн бүлэг, үйл ажиллагааны зорилгоо ойлгохын тулд харилцагчтай хамтран ажилладаг дэлгэрэнгүй загварчлалын зөвлөгөөний үйлчилгэээс эхэлдэг. Зарагдах тоглоомны үйлдвэр нь жижиг бусын урамшууллын бараанаас эхлээд том дэлгэцийн ширээгийн хүртэлх хэмжээний өөрчлөлт, брендийн өнгийг яг дахин үүсгэх өнгө тохируулах үйлчилгээ, органик материал, тусгай гадаргуугийн боловсруулалт, онцгой эдлэлүүдийн хослол зэрэг зууны орчим эдлэлийн сонголтоос текстурын сонголт зэрэг бараг хязгааргүй захидалтын боломжийг санал болгодог. Хэлбэрийг захидалтах чадвар нь тусгай барьцаа барилгын арга техник, шинэлэг загварын хөгжүүлэлтийг шаардсан абстракт дизайн, геометр хэлбэр, бүтээгдэхүүний хувилбар, дүр төрхийн тайлбар зэрэг уламжлалт амьтдын хэлбэрээс давж гардаг. Үйлдвэрийн тоног төхөөрөмж нь илүү их тэсвэртэй байдал, дүрсийн сайн харагдацыг бий болгохын тулд янз бүрийн материалыг хослуулсан уламжлалт цээжлэх, дулааны нийлүүлэлттэй холболтууд, хольсон арга замууд зэрэг олон арга барилыг хүлээн авдаг. Брендийн нэгдэлтийн сонголтуудад гэрээлсэн лого, дэлгэцийн график, дулааны шилжүүлэг, гурван хэмжээст элементүүдийг багтаасан бөгөөд эдгээр нь онцгой брендийн танихуйд тусладаг. Зарагдах тоглоомны үйлдвэр нь хурдан захидалт, улирлын кампанитай, хугацаа хамааралгүй хүргэлтийн шаардлагатай урт хугацааны үйлдвэрлэлийн гэрээтэй ажиллах боломжийг олгодог уян хатан үйлдвэрлэлийн хуваарьлалтын системийг хадгалдаг. Масштаблах чадвар нь чанар, хүргэлтийн хуваарьт нийцсэн хэвийн үйлдвэрлэлийн хэмжээнд шилжихэд чанар, хүргэлтийн хуваарьт нийцсэн прототипийн хэмжээг үйлдвэрлэх боломжийг олгодог. Сав баглах захидалт нь экологийн хувьд аюулгүй сонголтууд, премиум бэлгийн сав баглах, бүтээгдэхүүний харагдацыг сайжруулах, маркетингийн үр дүнтэй байдлыг нэмэгдүүлэх зорилготой борлуулалтын цэгийн дэлгэцийн шийдлүүдийг хамардаг. Үйлдвэр нь өөр өөр шаардлагатай олон төслийг зэрэг хийх чадвартай, үр ашигтай нөөцийн ашиглалт, хамгийн сайн хүргэлтийн хуваарьлалтыг хангаж чаддаг. Нөөцийн удирдлагын систем нь цэвэрлэгээний материалыг, боловсронги бүтээгдэхүүнийг хянах бөгөөд цаг хугацааны шаардлагыг хангах, харилцагчийн хадгалалтын зардлыг багасгахад тусалдаг. Зарагдах тоглоомны үйлдвэр нь бүх нарийн төвөгтэй шаардлагад нийцсэн бүтэн шийдэл хүргэхийн тулд үйлдвэрлэл, чанарын хяналт, логистикийн бүх аспектыг координаци хийх дэлгэрэнгүй төслийн удирдлагын үйлчилгээг санал болгодог. Холбоо харилцааны систем нь харилцагчид үйлдвэрлэлийн явцад тогтмол шинэчлэлтийг авах, тусгай хариуцлагатай менежерүүд асуултанд хариулах, үйлдвэрлэлийн явцад шаардлагатай өөрчлөлтүүдийг зохицуулах боломжийг олгодог.