empresas que fazem pelúcias personalizadas

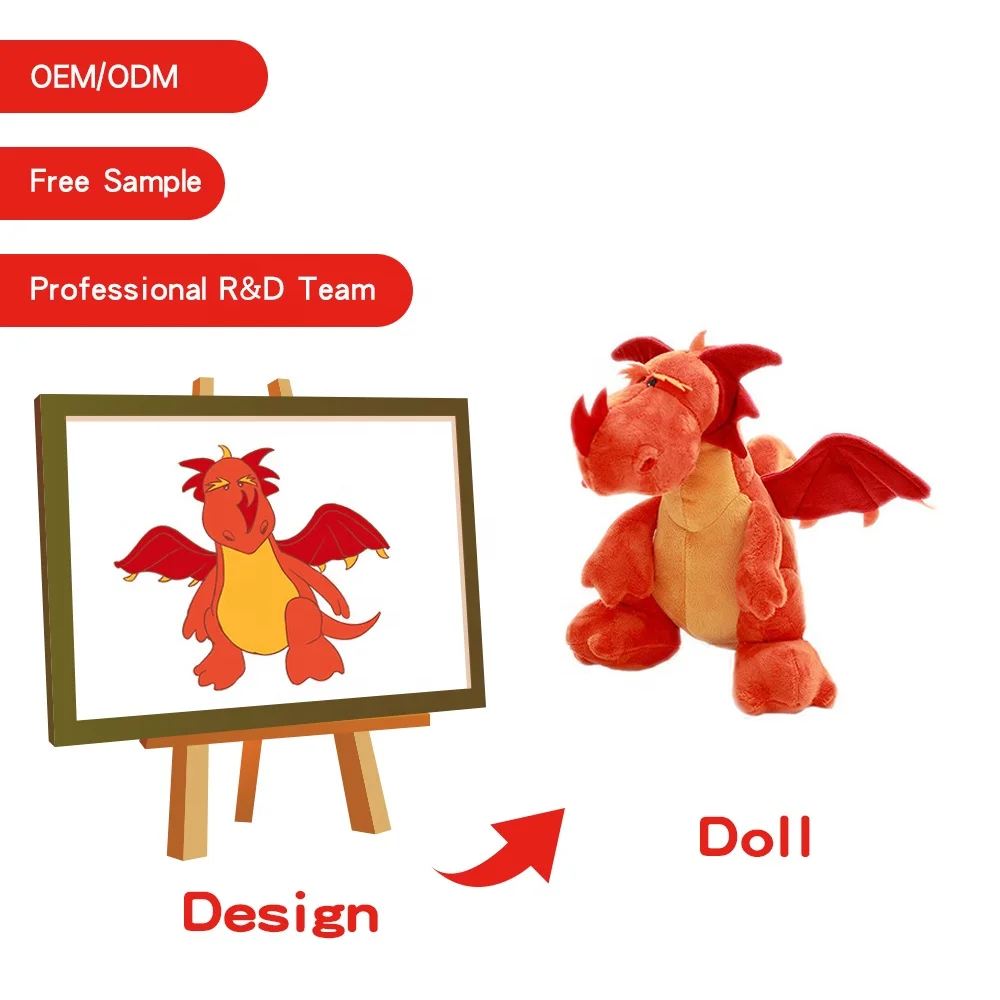

Empresas que produzem pelúcias personalizadas representam um segmento de indústria em expansão que transforma conceitos criativos em produtos tangíveis, com esculturas macias. Esses fabricantes especializados oferecem serviços completos de design à produção, atendendo empresas, organizações, artistas e indivíduos que buscam animais de pelúcia personalizados e brinquedos macios. As funções principais dessas empresas incluem consultoria de design, desenvolvimento de protótipos, aquisição de materiais, fabricação, controle de qualidade e serviços de expedição. Suas capacidades tecnológicas abrangem softwares de design assistido por computador para criação de moldes, máquinas de corte avançadas para formatos precisos de tecido, equipamentos industriais de costura para montagem e sistemas especiais de enchimento que garantem distribuição uniforme do recheio. Muitas empresas que produzem pelúcias personalizadas utilizam técnicas de impressão digital para designs intrincados, máquinas de bordado para detalhes finos e aplicações de sublimação para gráficos complexos. As tecnologias de garantia de qualidade incluem equipamentos automatizados para testes de durabilidade e sistemas de verificação de conformidade com normas de segurança. As aplicações da fabricação de pelúcias personalizadas abrangem diversos setores, incluindo campanhas de marketing corporativo nas quais mascotes personalizadas atuam como ferramentas promocionais, instituições educacionais criando produtos de incentivo ao espírito escolar, empresas de entretenimento produzindo mercadorias com personagens, organizações de saúde desenvolvendo brinquedos terapêuticos de conforto e empresas varejistas oferecendo opções de presentes personalizados. Empresas que produzem pelúcias personalizadas também atendem ao setor de jogos, produzindo personagens colecionáveis, equipes esportivas criando produtos para fãs e organizações sem fins lucrativos desenvolvendo produtos para arrecadação de fundos. O processo de fabricação normalmente envolve discussões iniciais sobre o conceito, criação de maquetes digitais, produção de amostras, ciclos de aprovação pelo cliente, fabricação em grande escala e embalagem final. Atualmente, muitas empresas que produzem pelúcias personalizadas oferecem plataformas online de design, permitindo que os clientes visualizem suas criações antes do início da produção. Essas plataformas se integram a sistemas de gestão de estoque, softwares de programação da produção e redes logísticas de transporte para garantir um processamento de pedidos e entrega contínuos.