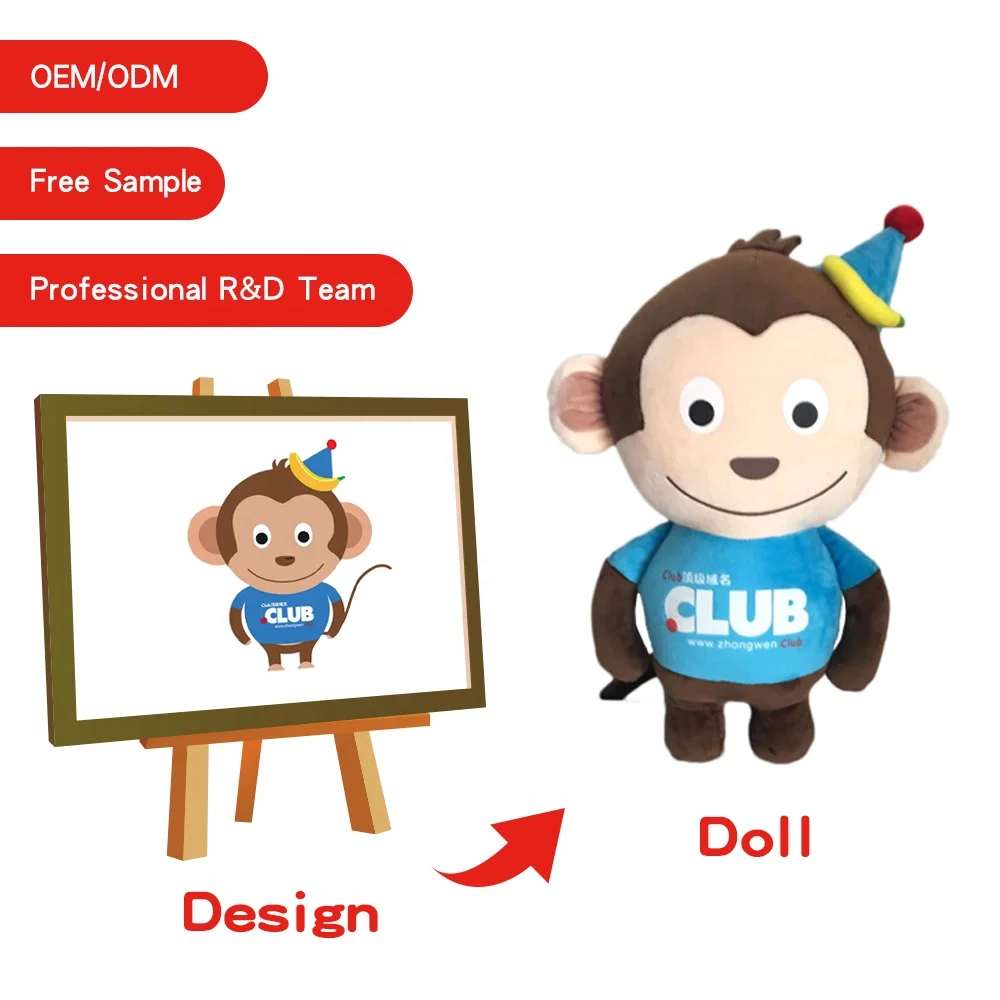

brinquedo de pelúcia feito sob medida

Brinquedo de pelúcia personalizado representa a fusão perfeita entre criatividade, artesanato e expressão pessoal no mundo dos brinquedos macios. Essas criações sob medida transformam a imaginação em realidade tangível e abraçável por meio de processos avançados de fabricação e atenção meticulosa aos detalhes. Diferentemente das alternativas produzidas em massa, cada brinquedo de pelúcia personalizado passa por cuidadosa consideração de design, seleção de materiais e construção de qualidade para atender requisitos específicos dos clientes. O processo de fabricação começa com consultas detalhadas nas quais os clientes compartilham sua visão, seja para recriar personagens queridos, comemorar ocasiões especiais ou dar vida a conceitos originais. Designers profissionais então traduzem essas ideias em especificações técnicas, levando em conta fatores como tamanho, textura, esquemas de cores e elementos funcionais. Tecnologias avançadas de impressão digital permitem a reprodução precisa de padrões intrincados, logotipos e ilustrações diretamente sobre superfícies de tecido premium. O fluxo de produção incorpora sistemas de design assistido por computador que garantem precisão dimensional e consistência entre múltiplas unidades. As medidas de controle de qualidade incluem testes rigorosos de durabilidade, conformidade com normas de segurança e resistência à descoloração, assegurando satisfação duradoura. A seleção de materiais desempenha um papel crucial, com opções que vão desde enchimentos de poliéster ultra-macio até alternativas hipoalergênicas adequadas para usuários sensíveis. Os tecidos superficiais incluem opções premium como algodão orgânico, minky luxuoso e têxteis especializados que proporcionam experiências táteis únicas. O processo de fabricação de brinquedos de pelúcia personalizados acomoda diversos níveis de complexidade, desde formas simples até designs elaborados com múltiplos componentes, partes móveis, módulos sonoros ou elementos interativos. As capacidades de produção estendem-se a diferentes categorias de tamanho, desde colecionáveis em miniatura até peças grandes e impactantes. Cada brinquedo de pelúcia personalizado recebe atenção individual durante a montagem, com artesãos qualificados garantindo costuras precisas, distribuição adequada do enchimento e acabamentos impecáveis que refletem a intenção original do design e superam as expectativas de qualidade.