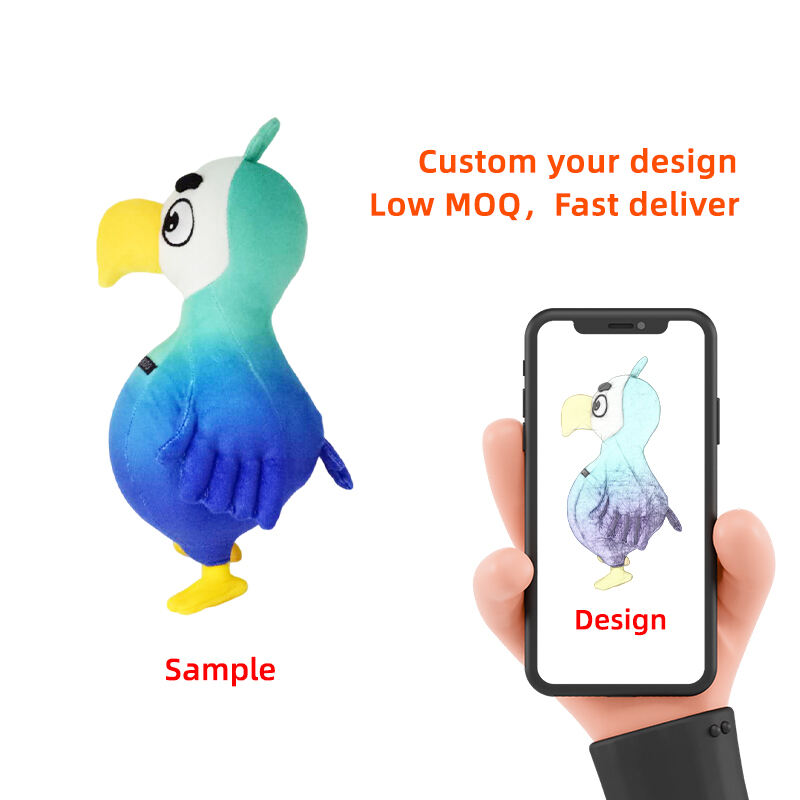

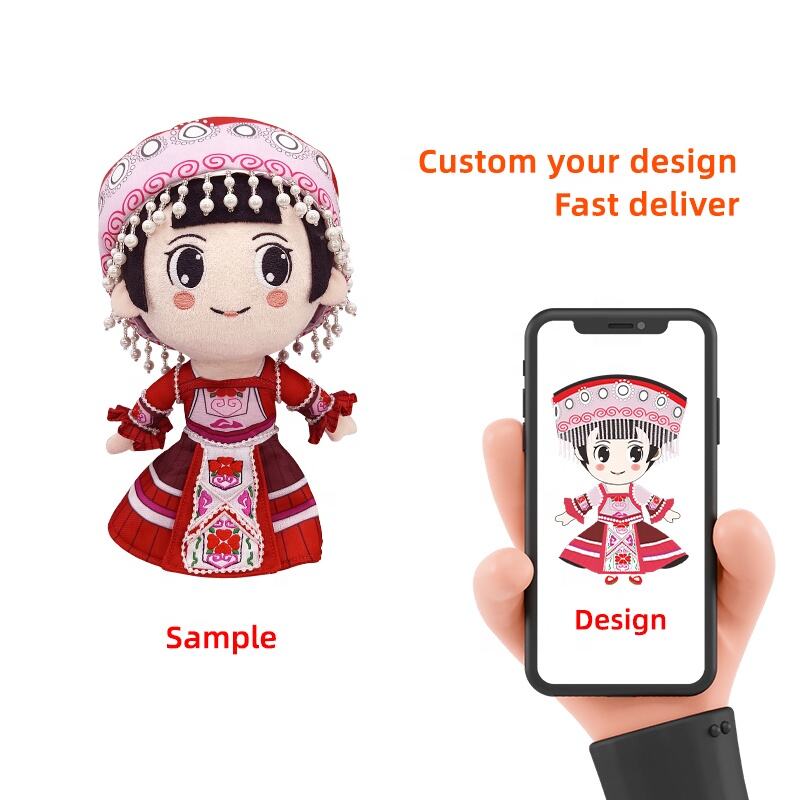

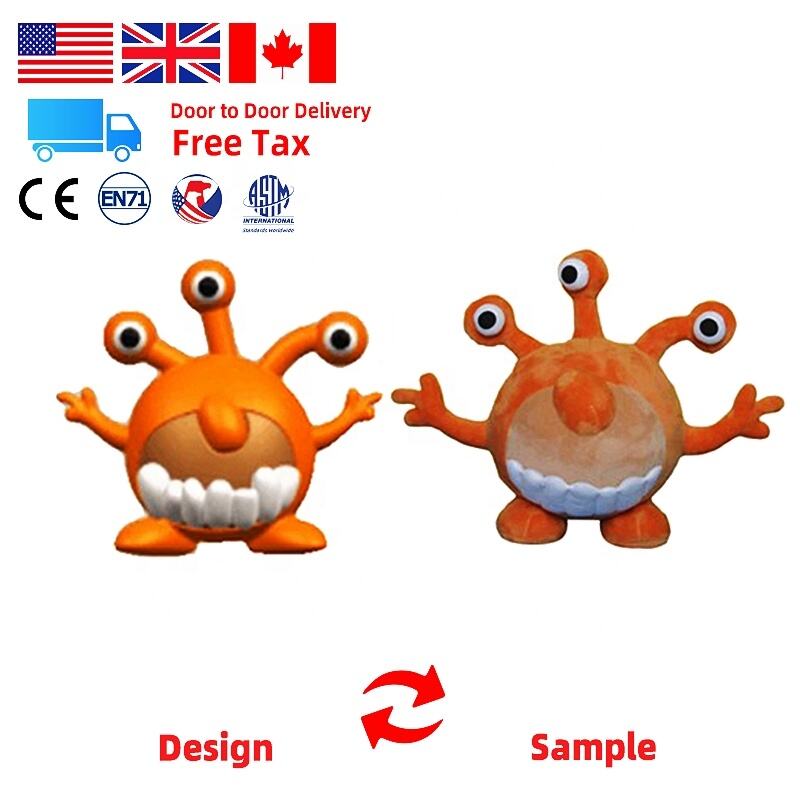

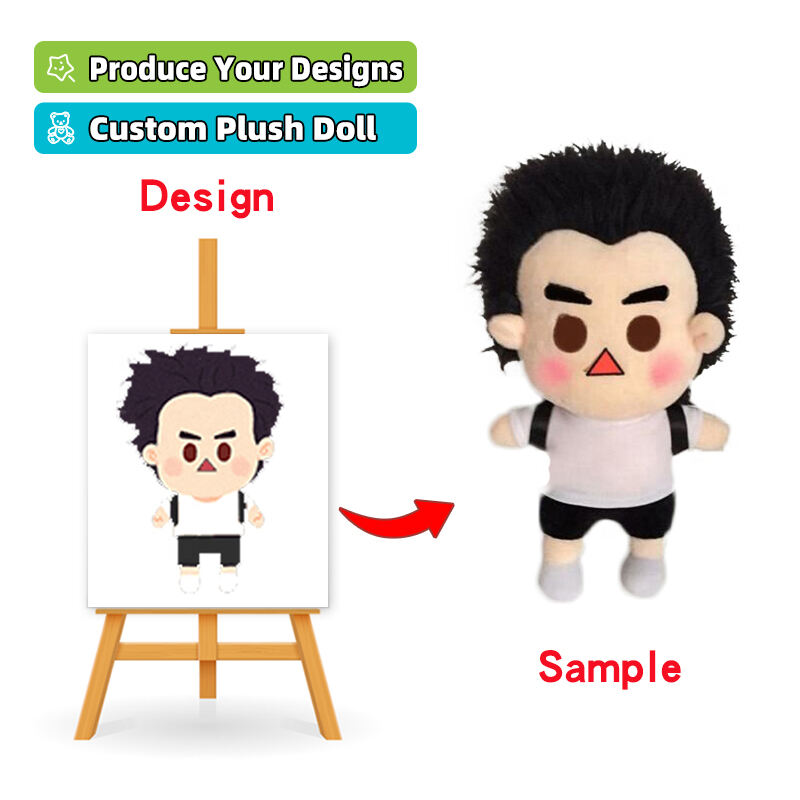

Customization and Market Adaptability

The inherent flexibility of plush toy making processes enables unprecedented customization capabilities that serve diverse market segments and create unique competitive advantages for manufacturers and retailers. Custom design services allow clients to transform concepts, artwork, or existing characters into tangible plush products through collaborative development processes that ensure perfect translation from vision to finished toy. Small-batch production capabilities in modern plush toy making operations accommodate specialty orders and limited edition releases without requiring minimum order quantities that traditionally excluded smaller businesses and independent creators. Rapid response manufacturing systems enable plush toy making facilities to capitalize on trending themes, seasonal opportunities, and viral phenomena by developing and producing relevant products within remarkably short timeframes. Material variety expands customization possibilities in plush toy making, offering options ranging from traditional plush fabrics to innovative textures, metallic finishes, and interactive elements that enhance play value and collector appeal. Size flexibility accommodates projects from miniature keychain accessories to oversized display pieces, ensuring plush toy making operations can serve every market segment and application. Personalization services including embroidered names, custom messages, and photograph integration create emotionally meaningful products that command premium pricing and generate exceptional customer loyalty. Corporate branding capabilities transform plush toy making into powerful marketing tools through accurate logo reproduction, color matching, and design elements that reinforce brand identity while providing memorable promotional items. International compliance expertise ensures plush toy making operations can navigate varying safety regulations, labeling requirements, and cultural preferences across global markets without compromising product integrity or delivery schedules. Technology integration including sound modules, LED lighting, and interactive features expands the possibilities within plush toy making while maintaining the essential comfort and safety characteristics that define the category. Quality control protocols adapt seamlessly to custom requirements, ensuring every specialized order meets the same rigorous standards as mass-produced items. These comprehensive customization capabilities establish plush toy making as an versatile manufacturing solution that grows with client needs while maintaining operational efficiency and profitability across diverse project scales and complexity levels.