plush toy manufacturer

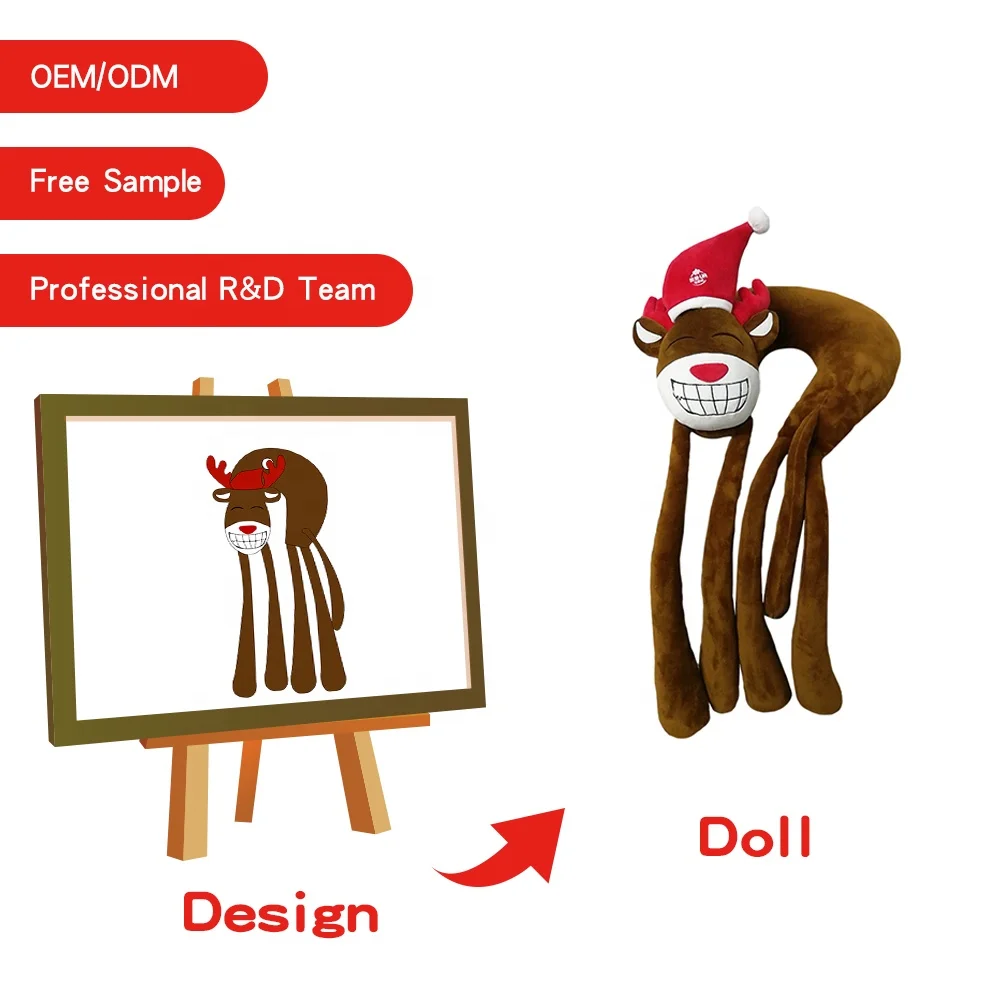

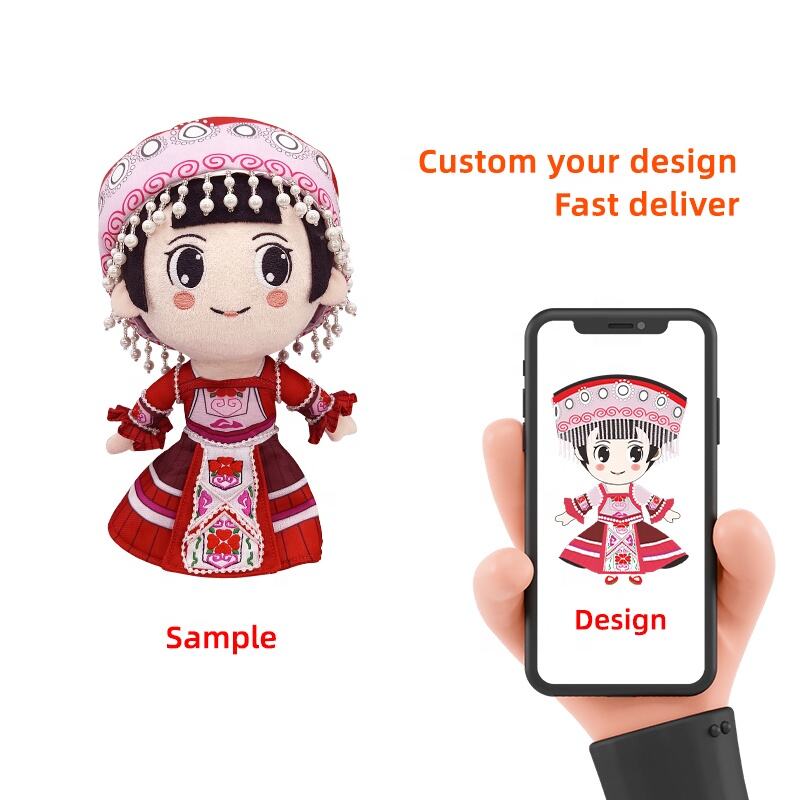

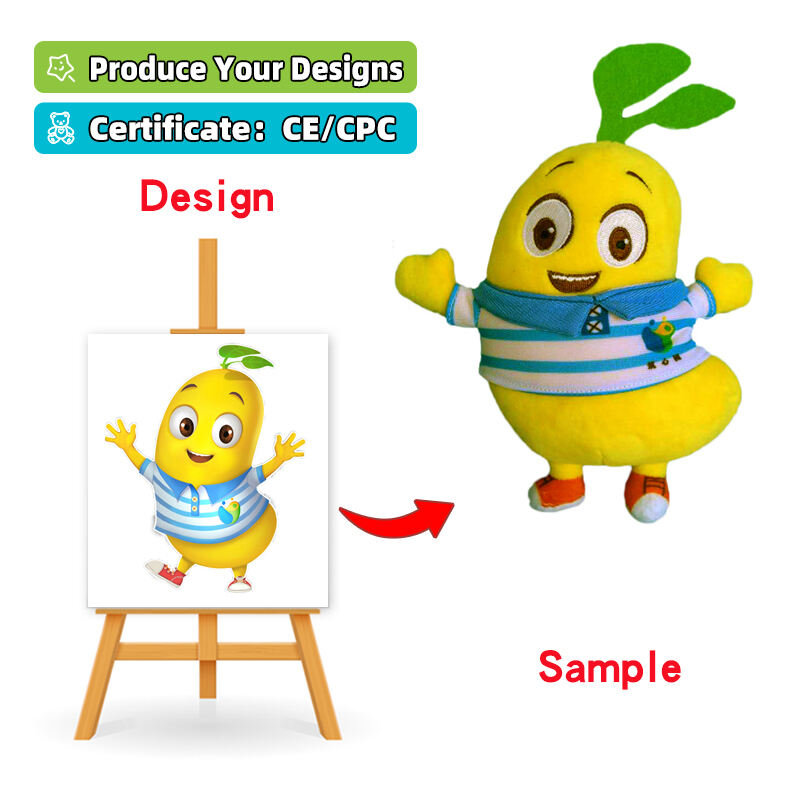

A professional plush toy manufacturer serves as the cornerstone of creating beloved soft toys that bring joy to children and adults worldwide. These specialized companies combine traditional craftsmanship with modern manufacturing techniques to produce high-quality stuffed animals, dolls, and collectible items. The primary function of a plush toy manufacturer encompasses the entire production cycle, from initial design conceptualization to final product delivery. They work closely with clients to transform creative ideas into tangible products that meet safety standards and market demands. Modern plush toy manufacturers utilize advanced production facilities equipped with computerized embroidery machines, precision cutting tools, and automated stuffing systems. These technological features enable consistent quality control while maintaining efficiency in large-scale production runs. The manufacturing process incorporates sophisticated quality assurance protocols, ensuring every product meets international safety regulations such as CE, CPSIA, and EN71 standards. Digital design software allows manufacturers to create detailed prototypes and 3D renderings before physical production begins, reducing development time and costs. Applications for plush toy manufacturers extend far beyond traditional toy production. They serve diverse industries including promotional merchandise, corporate gifts, educational tools, therapeutic aids, and licensed character products. Entertainment companies partner with manufacturers to create official merchandise for movies, television shows, and video games. Healthcare facilities utilize custom therapeutic plush toys for patient comfort and stress relief. Educational institutions commission manufacturers to produce mascots and learning aids that enhance student engagement. The versatility of modern plush toy manufacturers allows them to accommodate various materials, sizes, and complexity levels, from simple teddy bears to intricate multi-component designs featuring electronic components, sound modules, or interactive elements that respond to touch or movement.