Unlimited Creative Possibilities

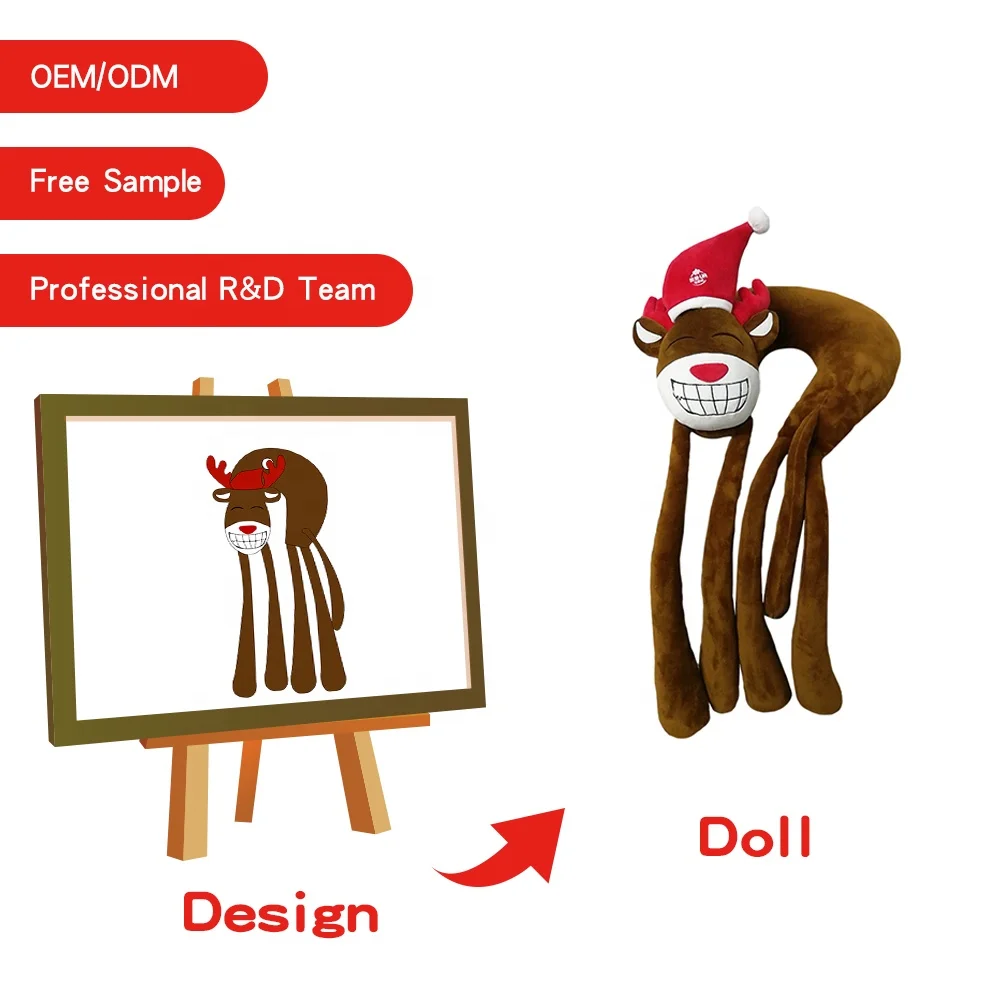

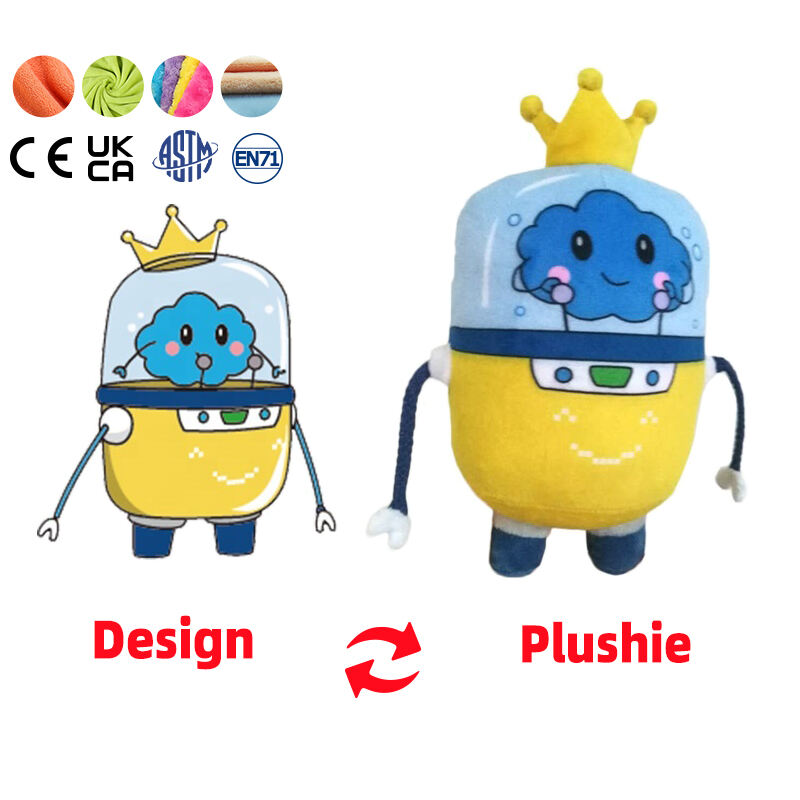

The creative freedom offered by plushie custom services opens infinite possibilities for bringing imaginative concepts to life through expertly crafted soft toys. Unlike conventional retail options that limit choices to existing inventory, plushie custom manufacturing encourages clients to explore their creativity without constraints, resulting in truly unique products that reflect personal style and preferences. Character development represents a significant aspect of plushie custom services, where clients can create original mascots, transform beloved pets into plush form, or develop educational characters that serve specific learning objectives. Size customization in plushie custom production ranges from miniature keychain versions to oversized display pieces, accommodating various applications and space requirements. Fabric selection for plushie custom projects encompasses an extensive range of textures, colors, and properties, including hypoallergenic materials for sensitive users and specialized fabrics that enhance durability or provide specific tactile experiences. Feature integration within plushie custom designs can include sound modules, LED lighting, removable accessories, or interactive elements that transform simple stuffed animals into engaging, multi-functional products. Cultural and religious considerations can be incorporated into plushie custom designs, ensuring appropriate representation and respect for diverse backgrounds and beliefs. Seasonal and holiday themes provide opportunities for limited-edition plushie custom creations that celebrate special occasions or commemorate important events. Collaborative design processes allow multiple stakeholders to contribute to plushie custom concepts, making them ideal for group projects, fundraising initiatives, or community-based programs. The ability to incorporate personal memorabilia, such as fabric from special clothing or hair samples from beloved pets, adds emotional significance to plushie custom products that extends beyond mere aesthetics. Prototype development services enable clients to test and refine their plushie custom concepts before committing to larger production quantities, reducing risk and ensuring optimal outcomes.