stuffed toy manufacturers

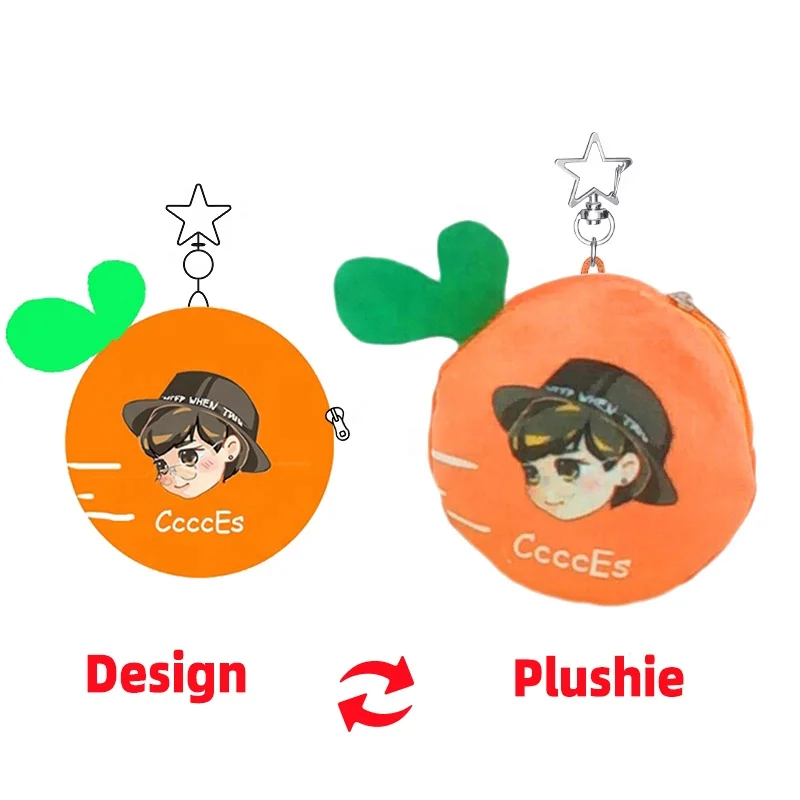

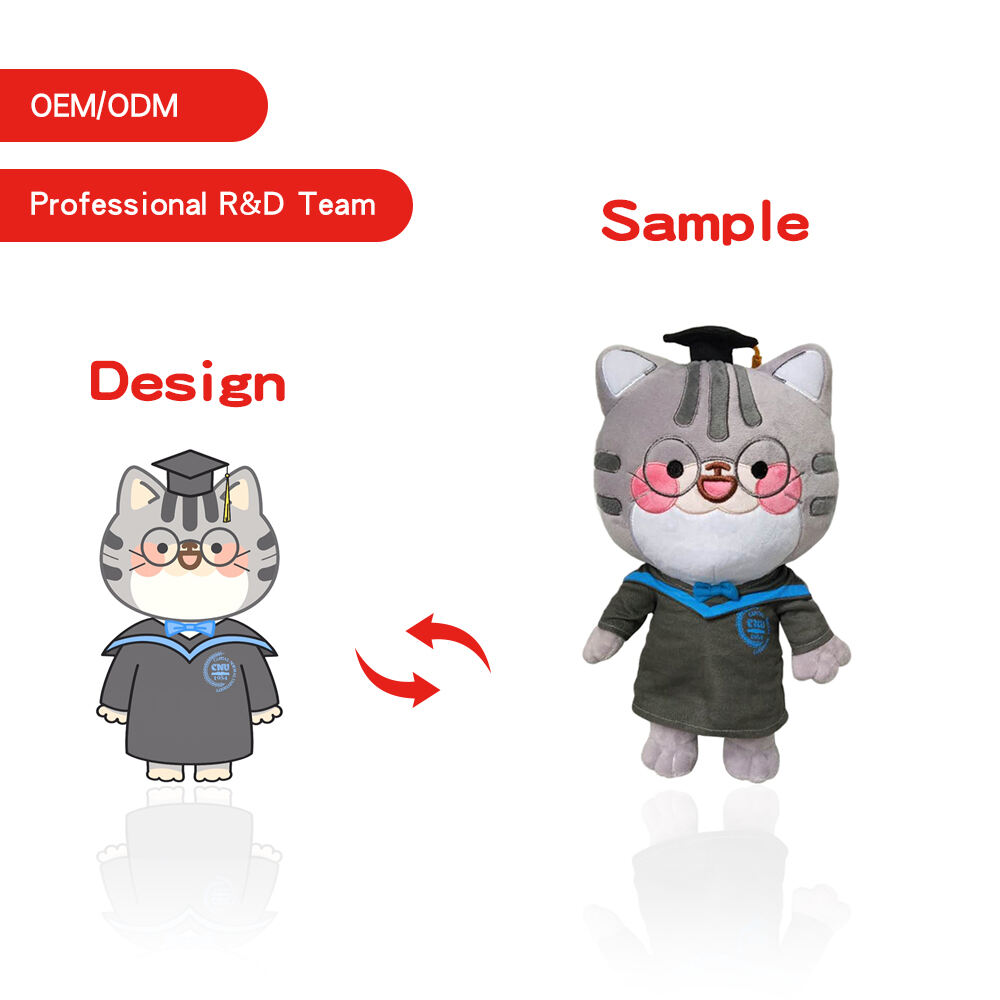

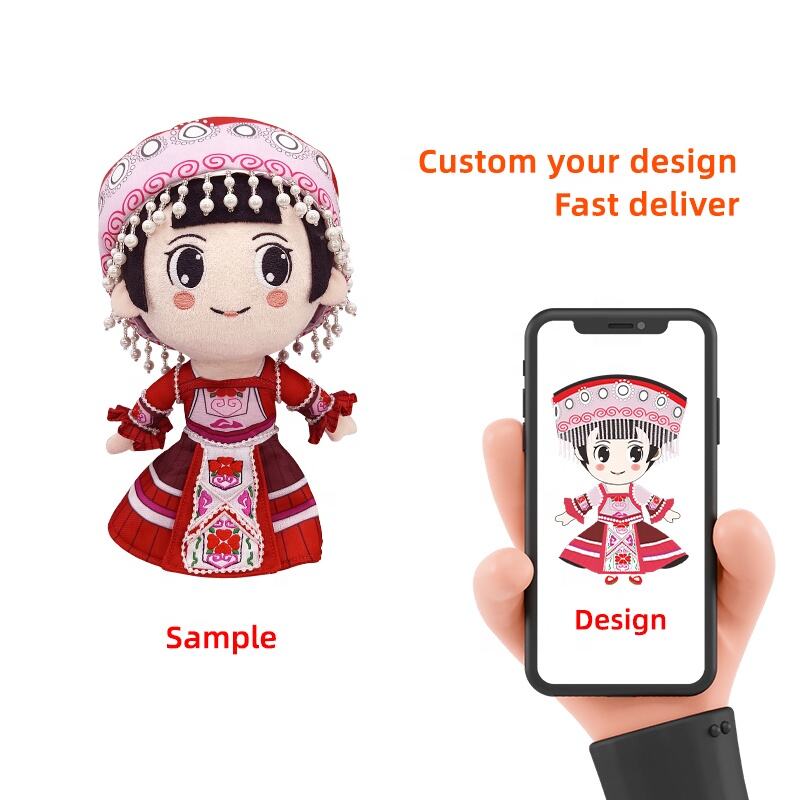

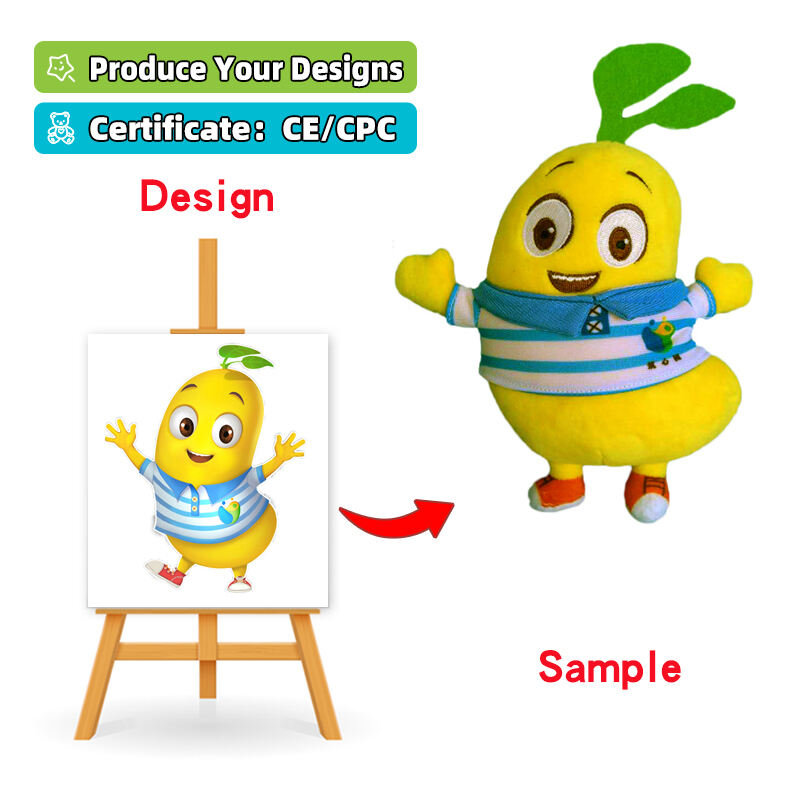

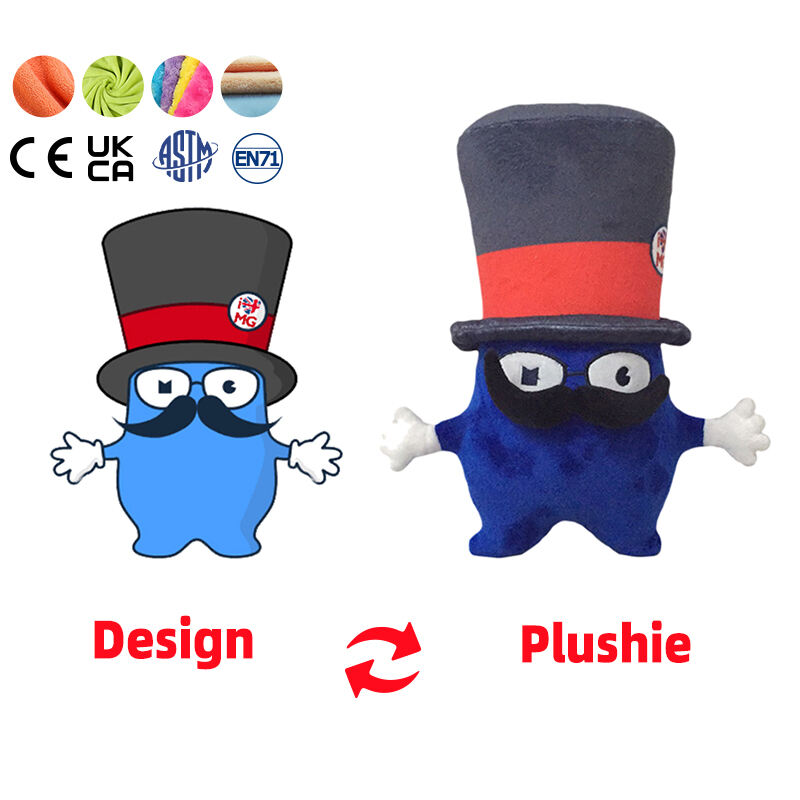

Stuffed toy manufacturers represent the backbone of a multi-billion-dollar global industry that creates beloved companions for children and collectors worldwide. These specialized companies operate sophisticated production facilities equipped with cutting-edge machinery, quality control systems, and design capabilities that transform raw materials into cherished plush products. Modern stuffed toy manufacturers utilize advanced textile technologies, computerized embroidery systems, and precision filling equipment to create products that meet stringent safety standards while maintaining exceptional softness and durability. The primary function of these manufacturers extends beyond simple production, encompassing comprehensive services including custom design development, prototype creation, mass production, packaging, and distribution coordination. Leading stuffed toy manufacturers employ teams of skilled designers who work closely with licensing partners, retailers, and brand owners to develop products that capture market trends and consumer preferences. Their technological infrastructure includes automated cutting systems that ensure precise fabric patterns, specialized sewing equipment designed for three-dimensional construction, and advanced stuffing machinery that creates consistent density and shape retention. Quality assurance laboratories within these facilities conduct rigorous testing protocols, including safety assessments for small parts, flammability resistance, and chemical composition analysis to comply with international toy safety regulations such as CPSC, EN71, and ASTM standards. The applications for stuffed toy manufacturers span diverse market segments including traditional toy retail, promotional merchandise, educational tools, therapeutic products, and collectible items. Many manufacturers specialize in specific categories such as licensed character products, custom corporate mascots, or premium collector editions that require specialized materials and construction techniques. The integration of sustainable practices has become increasingly important, with leading stuffed toy manufacturers implementing eco-friendly materials, renewable energy systems, and waste reduction programs throughout their production processes. These companies serve as critical partners for major toy brands, entertainment companies, and retail chains by providing scalable manufacturing solutions that can accommodate both small custom orders and large-scale production runs while maintaining consistent quality standards and competitive pricing structures.