Finding the right custom plush maker can make the difference between bringing your creative vision to life and facing unexpected disappointments. Whether you're developing a brand mascot, creating promotional merchandise, or launching a new toy line, selecting the ideal manufacturing partner requires careful consideration. The plush toy industry has evolved significantly, with manufacturers offering varying levels of quality, customization options, and service standards. Understanding what questions to ask before committing to a partnership will save you time, money, and potential headaches down the road.

Understanding Production Capabilities and Specializations

Manufacturing Experience and Track Record

The experience level of your chosen custom plush maker directly impacts the quality and reliability of your final product. Established manufacturers typically have refined production processes, quality control systems, and problem-solving capabilities developed through years of operation. Ask potential partners about their years in business, the types of projects they've completed, and their client portfolio. A reputable custom plush maker should be willing to share case studies, testimonials, or examples of previous work that demonstrate their expertise in your specific requirements.

Production volume capabilities represent another crucial factor in your selection process. Some manufacturers excel at small batch orders, while others are optimized for large-scale production runs. Understanding minimum order quantities, production capacity, and scalability options helps ensure your chosen partner can accommodate both your immediate needs and future growth plans. Additionally, inquire about their ability to handle rush orders or seasonal fluctuations in demand.

Design and Customization Options

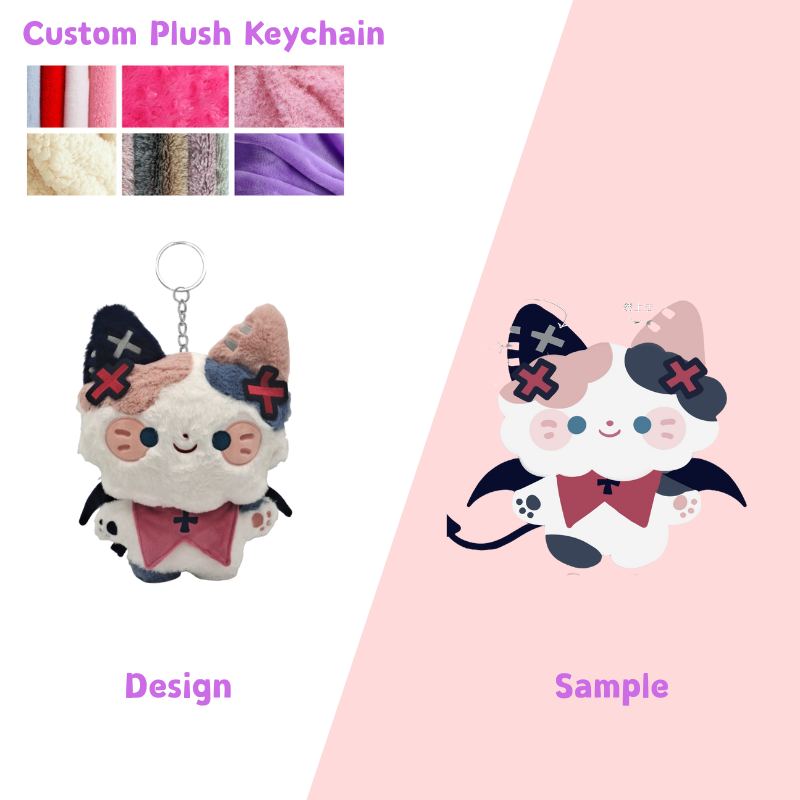

The scope of customization services offered by different manufacturers varies considerably across the industry. A skilled custom plush maker should provide comprehensive design support, from initial concept development to final production specifications. Ask about their design team's capabilities, software tools used, and the level of input you can provide throughout the creative process. Some manufacturers offer 3D modeling services, prototype development, and iterative design refinement to ensure your vision is accurately captured.

Material selection represents a critical aspect of customization that affects both appearance and production costs. Quality manufacturers maintain extensive fabric libraries, offering various textures, colors, and specialty materials like organic cotton, recycled polyester, or flame-retardant options. Understanding available material choices and their respective properties helps you make informed decisions about durability, safety compliance, and market positioning for your finished products.

Quality Standards and Manufacturing Processes

Quality Control Systems

Comprehensive quality control systems distinguish professional manufacturers from less reliable options in the competitive plush toy market. A reputable custom plush maker should implement multi-stage inspection processes, from incoming material verification through final product approval. Ask about their quality checkpoints, testing procedures, and defect rates to understand how they maintain consistent standards across production runs.

Documentation and traceability systems provide valuable insights into a manufacturer's operational sophistication. Professional facilities maintain detailed records of production batches, material sources, and quality test results. This documentation becomes essential for regulatory compliance, warranty claims, and continuous improvement initiatives. Inquire about their record-keeping practices and how they handle quality issues when they arise.

Safety Certifications and Compliance

Safety compliance represents a non-negotiable requirement for any custom plush maker serving consumer markets. Different regions maintain specific safety standards for toys and children's products, including regulations about chemical content, choking hazards, and flammability. Your chosen manufacturer should possess relevant certifications such as CE marking for European markets, CPSIA compliance for the United States, or equivalent standards for your target regions.

Testing capabilities and third-party validation provide additional assurance of safety compliance. Many manufacturers maintain in-house testing facilities or partnerships with accredited laboratories to verify their products meet required standards. Ask about their testing protocols, frequency of safety audits, and how they stay current with evolving regulations in different markets.

Pricing Structure and Cost Considerations

Transparent Pricing Models

Understanding the complete cost structure helps you make informed decisions and avoid unexpected expenses during production. A professional custom plush maker should provide detailed quotations that break down material costs, labor charges, tooling fees, and any additional services. This transparency allows you to identify cost optimization opportunities and compare quotes accurately across different manufacturers.

Hidden costs can significantly impact your project budget if not identified early in the selection process. Common additional charges include design revision fees, expedited production costs, packaging modifications, and shipping expenses. Ask for a comprehensive list of potential extra charges and under what circumstances they might apply to your specific project requirements.

Payment Terms and Financial Security

Payment structure negotiations reflect both the manufacturer's business practices and your risk tolerance. Established manufacturers typically offer flexible payment terms that balance cash flow considerations with production milestones. Standard arrangements might include partial deposits upon order confirmation, progress payments during production, and final balance upon completion. Understanding these terms helps you plan your financial commitments and assess the manufacturer's confidence in their delivery capabilities.

Financial security measures protect both parties throughout the production relationship. Some manufacturers offer production guarantees, quality warranties, or performance bonds that provide recourse if deliverables don't meet agreed specifications. These protections become particularly important for large orders or critical product launches where delays or quality issues could have significant business impacts.

Communication and Project Management

Communication Protocols

Effective communication forms the foundation of successful partnerships between clients and manufacturers. A professional custom plush maker should establish clear communication channels, designated points of contact, and regular update schedules that keep you informed throughout the production process. Ask about their preferred communication methods, response time commitments, and how they handle urgent issues or design changes.

Language capabilities and cultural understanding become increasingly important when working with international manufacturers. While many global suppliers offer English-speaking representatives, the depth of communication and cultural alignment can vary significantly. Assess the manufacturer's ability to understand your market requirements, design preferences, and business objectives to ensure smooth collaboration.

Project Timeline Management

Realistic timeline development requires understanding all phases of the production process, from initial design through final delivery. An experienced custom plush maker should provide detailed project schedules that account for design development, prototype creation, production setup, manufacturing time, quality control, and shipping logistics. These timelines help you plan product launches, inventory management, and marketing campaigns effectively.

Contingency planning demonstrates a manufacturer's operational maturity and commitment to meeting deadlines. Ask about their approaches to handling potential delays, alternative sourcing options for materials, and communication protocols for schedule adjustments. Understanding how they manage unexpected challenges provides insight into their reliability and problem-solving capabilities.

FAQ

What minimum order quantities should I expect from a custom plush maker?

Minimum order quantities vary significantly across different manufacturers, typically ranging from 100 pieces for specialized small-batch producers to 1,000 or more pieces for large-scale facilities. The complexity of your design, number of colors, and customization requirements all influence minimum orders. Some custom plush maker companies offer prototype services with very low minimums to help you test market demand before committing to larger production runs.

How long does the typical custom plush production process take?

Standard production timelines for custom plush projects typically range from 4-8 weeks after design approval, depending on order complexity and quantity. This includes pattern development, material sourcing, production setup, manufacturing, and quality control processes. Rush orders may be available for additional fees, while complex designs or specialized materials could extend timelines. A reliable custom plush maker will provide detailed schedules and milestone dates during the quotation process.

What design files or specifications do I need to provide?

Most manufacturers can work with various design inputs, from hand-drawn sketches to detailed digital artwork. High-resolution images, color specifications, size requirements, and any special features should be clearly documented. Many custom plush maker facilities offer design services to help refine your concept and create technical specifications. Providing reference materials, competitor examples, or mood boards helps communicate your vision more effectively to the design team.

How can I verify the quality and reliability of a potential manufacturer?

Verification methods include requesting samples of previous work, checking client references and testimonials, reviewing certifications and compliance documentation, and conducting virtual or in-person facility tours. A reputable custom plush maker should willingly provide portfolio examples, connect you with existing clients for feedback, and demonstrate their quality control processes. Third-party verification through industry associations or trade organizations can also provide additional credibility confirmation.