proizvođač prilagođenih mehurih igračaka

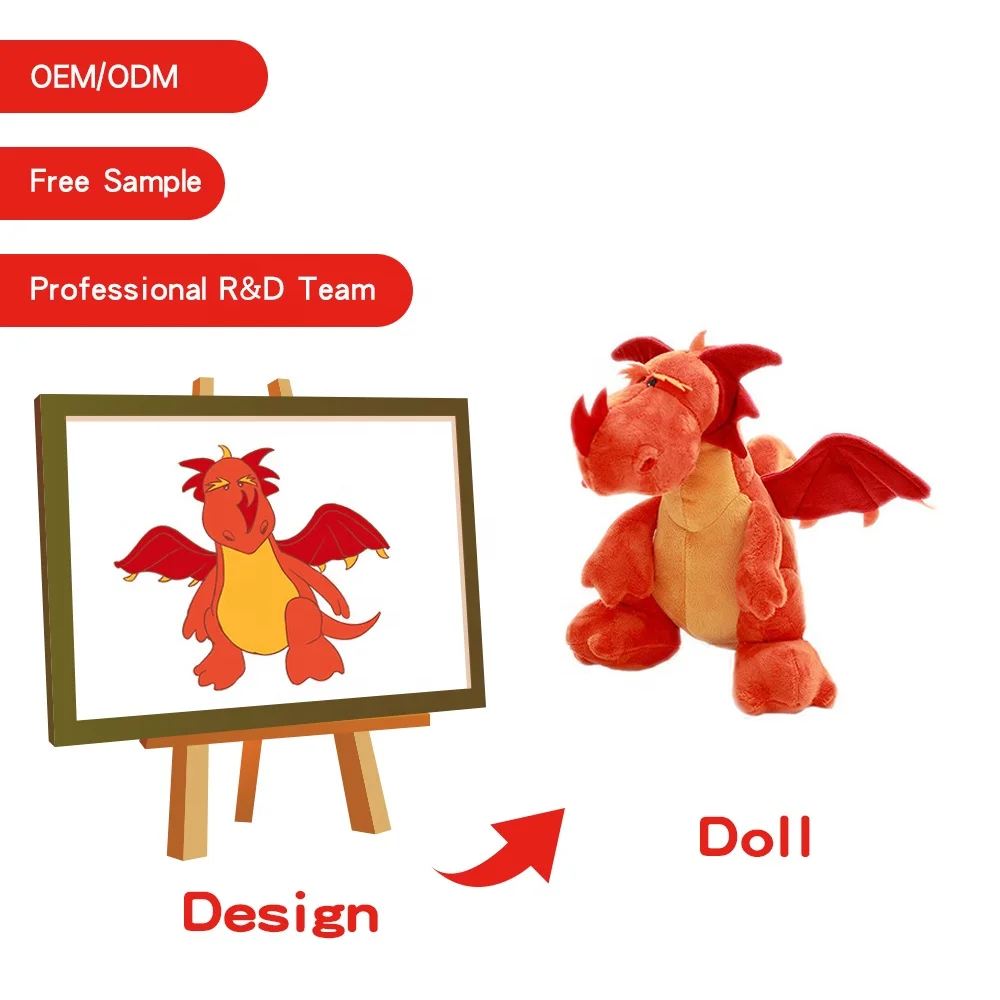

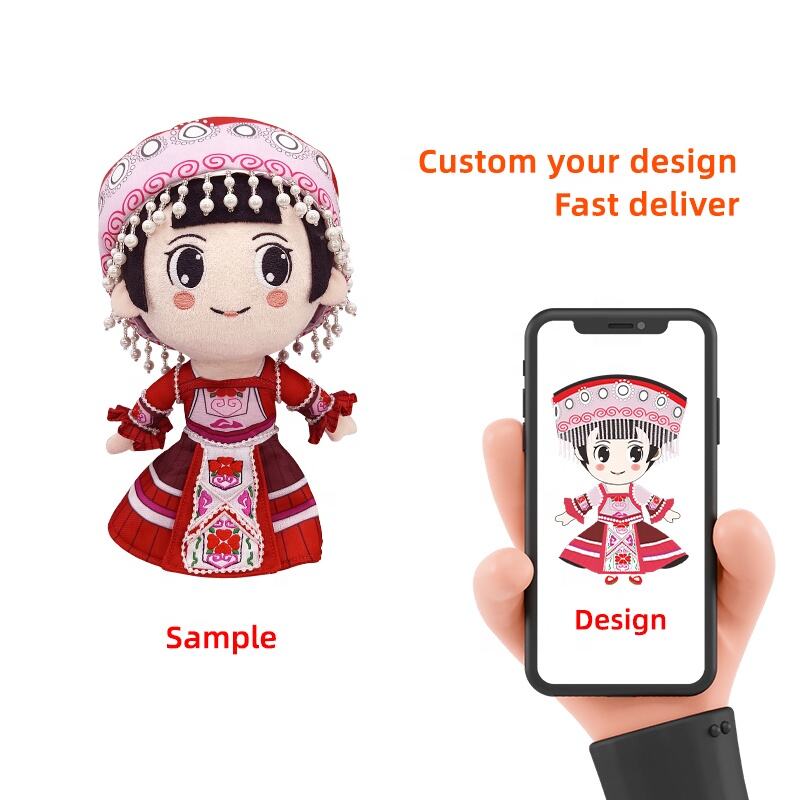

Proizvođač prilagođenih plišanih igračaka djeluje kao specijalizirani partnerski proizvođač koji kreativne ideje pretvara u konkretna, visokokvalitetna životinjska bića i meke igračke. Ovi proizvođači posjeduju sofisticirane pogone opremljene naprednom opremom, vještim obrtnicima te sveobuhvatnim sustavima kontrole kvalitete kako bi isporučili personalizirane plišane proizvode koji zadovoljavaju specifične zahtjeve klijenata. Glavna uloga proizvođača prilagođenih plišanih igračaka je suradnja s tvrtkama, organizacijama i pojedincima u stvaranju jedinstvenih dizajna plišanih igračaka koji odražavaju identitet brenda, obilježavaju posebne događaje ili zadovoljavaju određene tržišne potrebe. Proizvodni proces započinje detaljnim savjetovanjima tijekom kojih klijenti prezentiraju svoje vizije, skice ili postojeće uzorke. Stručni timovi za dizajn zatim koriste softver za računalno podržano projektiranje i stručno znanje iz područja izrade kalupa kako bi kreirali tehničke specifikacije i prototipove. Savremeni proizvođači prilagođenih plišanih igračaka koriste najnovije tehnologije uključujući 3D modeliranje, automatske uređaje za rezanje i preciznu opremu za vezenje kako bi osigurali točnost i dosljednost tijekom cijelog proizvodnog procesa. Ovi pogoni vode opsežne baze materijala s različitim tkaninama, punjenjima i priborom nabavljenim od certificiranih dobavljača koji se pridržavaju međunarodnih sigurnosnih standarda. Protokoli jamstva kvalitete uključuju više faza inspekcije, od provjere sirovina do testiranja gotovih proizvoda, osiguravajući time sukladnost s sigurnosnim propisima poput CPSIA, EN71 i CE standarda. Tehnološka infrastruktura proizvođača prilagođenih plišanih igračaka obično uključuje digitalizirane uređaje za vezenje sposobne za složene dizajne, sisteme za termalni transfer print za detaljne grafičke elemente te specijaliziranu šivaću opremu za složene tehnike izrade. Primjena prilagođenih plišanih igračaka obuhvaća brojne industrije i svrhe, uključujući korporativne promocijske artikle, trgovačko asortiman, edukacijska pomagala, terapijske alate, proizvode za prikupljanje sredstava i personalizirane poklone. Kompanije iz zabavne industrije često surađuju s proizvođačima prilagođenih plišanih igračaka u izradi robne markice likova, dok zdravstvene organizacije koriste terapijske plišane igračke u programima za udobnost pacijenata. Obrazovne institucije naručuju prilagođene maskote u plišu kako bi poboljšale duh škole i prepoznatljivost brenda.