פתרונות התאמה שותפות מותג

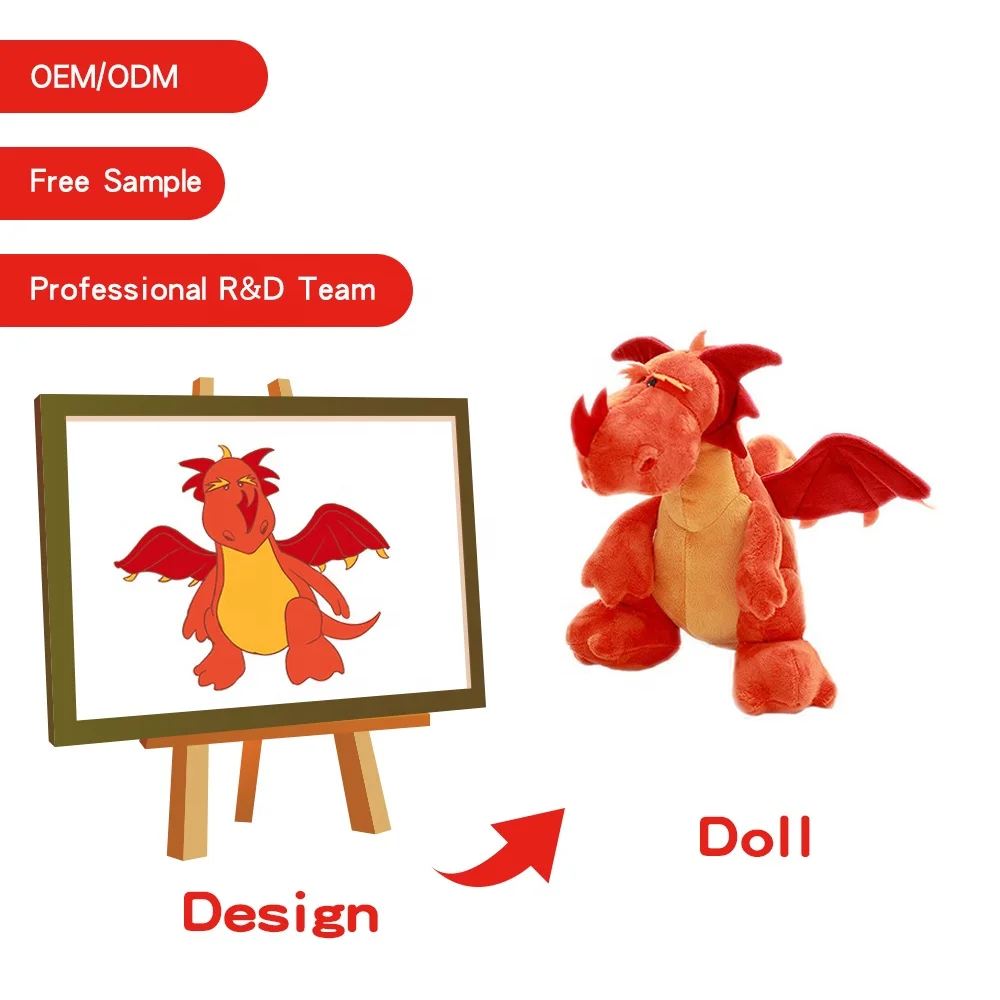

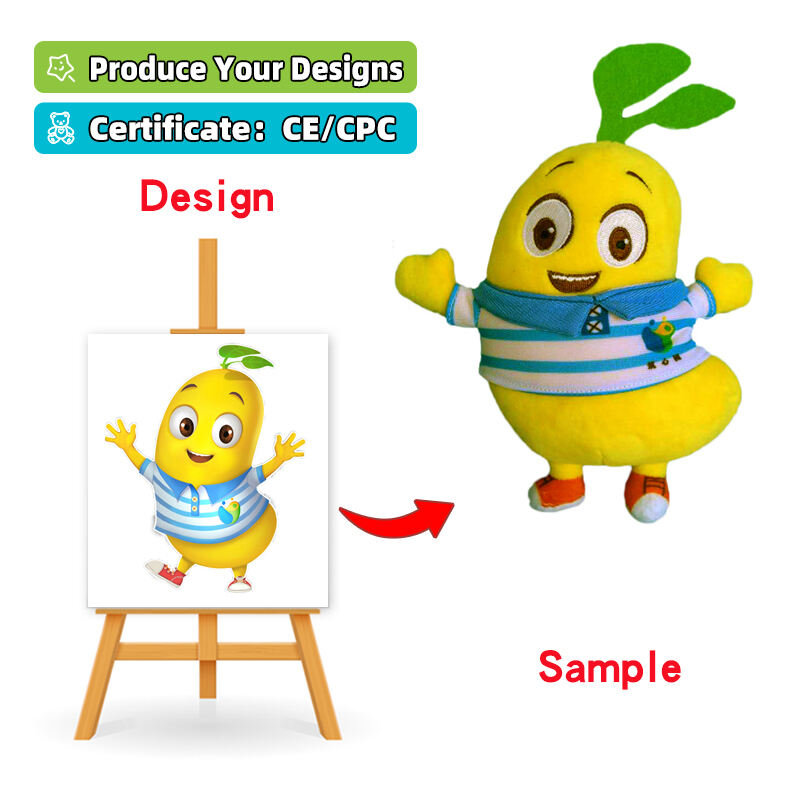

חברות מובילות בתחום צעצועי הפלש מצטיינות בסיוע בהגשמת פתרונות התאמה והợשקółות יוקרה שמעבירים רעיונות יצירתיים למוצר מוכן לשיווק, ובכך תומכות במגוון יעדי עסקים ואסטרטגיות שיווק. הארגונים הללו מחזיקים בצוותי עיצוב מיוחדים המורכבים מאומנים, מהנדסים ופיתוחנים אשר עובדים בשיתוף פעולה הדוק עם לקוחות על מנת להפוך זהויות מותגות, עיצובי דמויות ורעיונות קידום למוצרי פלש מוחשיים, המגלמים באופן מדויק את המסרים והיעדים האסתטיים שנקבעו. יכולות מתקדמות של דוגמיות מאפשרות פיתוח מהיר של דגמי ניסוי באמצעות מגוון חומרים, טכניקות בנייה ואפשרויות גימור, ומאפשרות ללקוחות להעריך מספר גרסאות עיצוב לפני סגירת مواصفות הייצור הסופיות וההתחייבויות הפיננסיות. מערכות ייצור גמישות מספקות הזמנות בגודל משתנה, החל מכמויות קטנות לקידום וכלה הפצה רחבה ברשתות קמעונאיות, ומספקות פתרונות מתכ-scalable התומכים במודלי עסקים שונים ואסטרטגיות שיווק. מומחיות בתיאום צבעים מבטיחה שכפול מדויק של צבעי תאגיד, דרישות דמויות והנחיות מותג, באמצעות מערכות צביעה מתקדמות ותהליכי בקרת איכות שמונעים עקביות לאורך כל קו המוצרים. פרוטוקולי הגנת רכוש רוחני שומרים על עיצובים פרטיים, הסכמים על זיכיון ומידע סודי לאורך כל שלבי הפיתוח והייצור, ומבטיחים שלווה לבעלי המותגים וליוצרים. שירותי ניהול פרויקטים משנים מסעキャンペーン מורכבות של מוצרים מרובים, מנהלים לוחות זמנים לייצור ומקלים על תקשורת בין בעלי עניין, כדי להבטיח השלמת הפרויקט בהצלחה בתוך הפרמטרים של זמן ותקציב. אפשרויות התאמה של אריזה כוללות קופסאות ממותגות, תגי תלול, מדורי טיפול ודפי הנחיה, והכנסות שיפור לעיצוב המוצר ותומכות באסטרטגיות שיווק תוך שמירה על יעילות עלות. יכולות ייצור והפצה בינלאומיות מאפשרות השקת מוצרים גלובלית, התאמות לשוקות אזוריים ודרישות אריזה מקומיות, התומכות באסטרטגיות הרחבת מותג עולמית. שירותים לאחר ייצור כוללים ניהול מלאי, הסכמים למשלוח ישיר ותמיכה בביצוע, אשר מפשיטים תהליכי הפצה ומצמצמים עומסים אופרטיביים עבור שותפי המותג. ניטור עקביות איכות מבטיח שמוצרי ההזרמה יקיימו את התקנים שהוגדרו לאורך כל שרשרת הייצור, ומשמר את מוניטין המותג ואת שביעות הרצון של הלקוחות בכל שוקות היעד. יכולות ההתאמה המקיפות הללו מקימות את חברות צעצועי הפלש כשותפות אסטרטגיות ערכיות, המסוגלות לתמוך ביוזמות מותג מורכבות, תוך כדי מסירת מוצרים יוצאי דופן שפוגעים בציבור היעד ומצליחים מסחרית.