Зохицуулалтын чадвар болон зургийн шинэчлэл

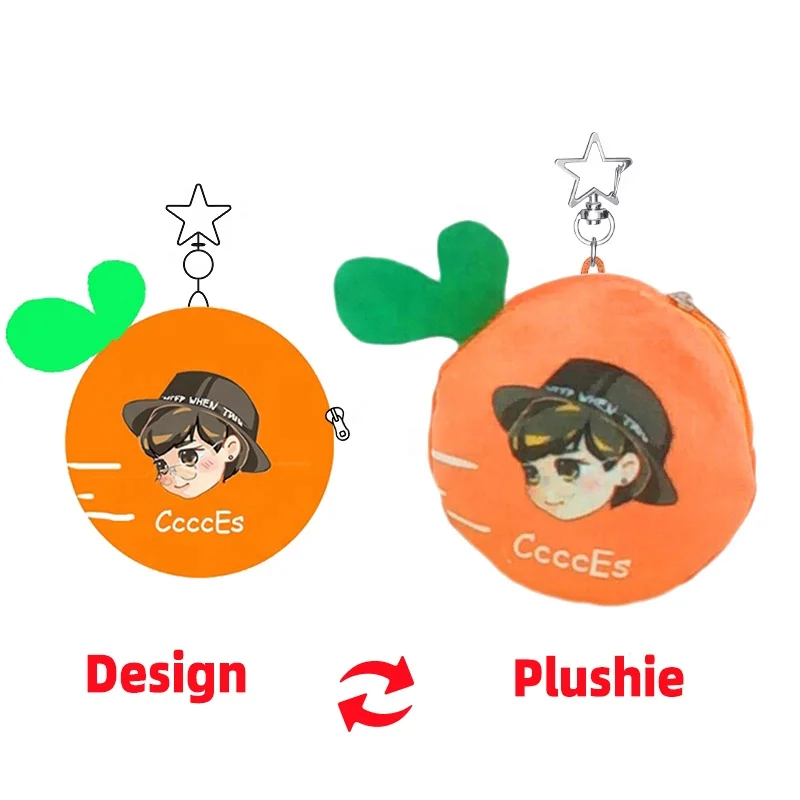

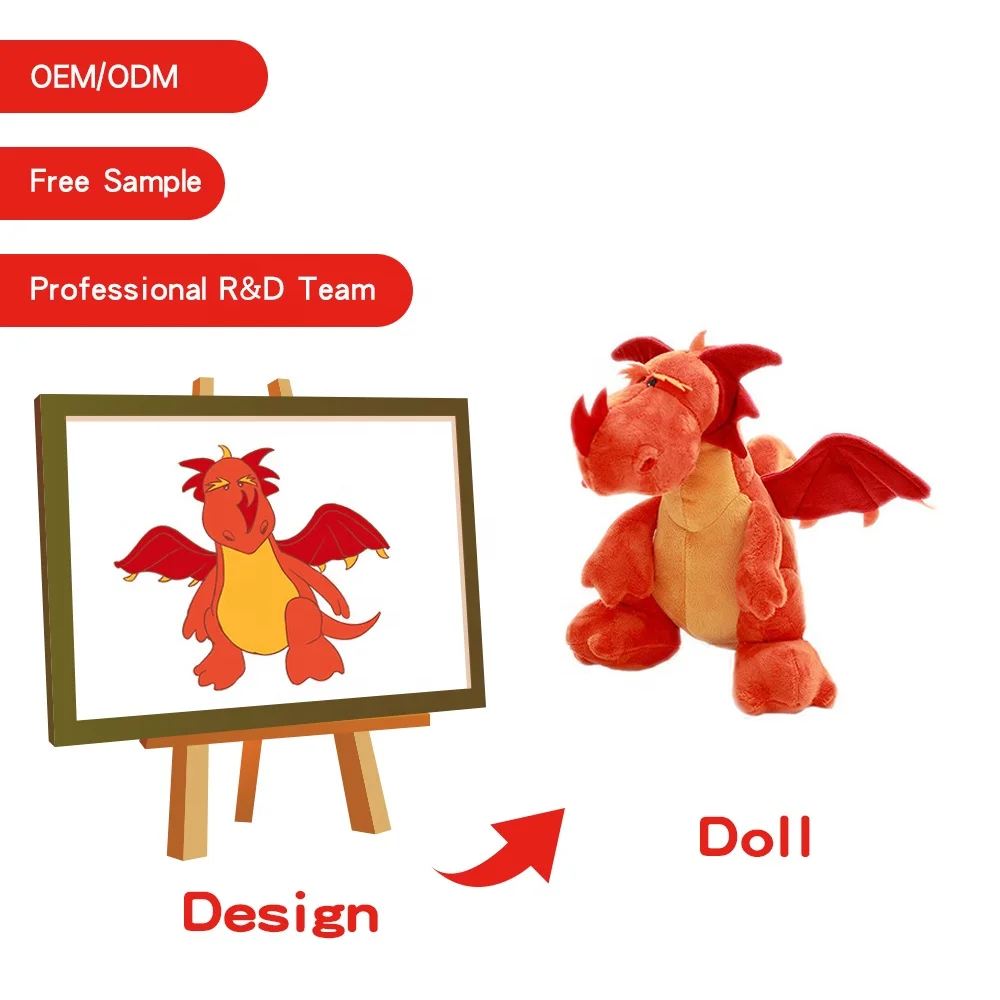

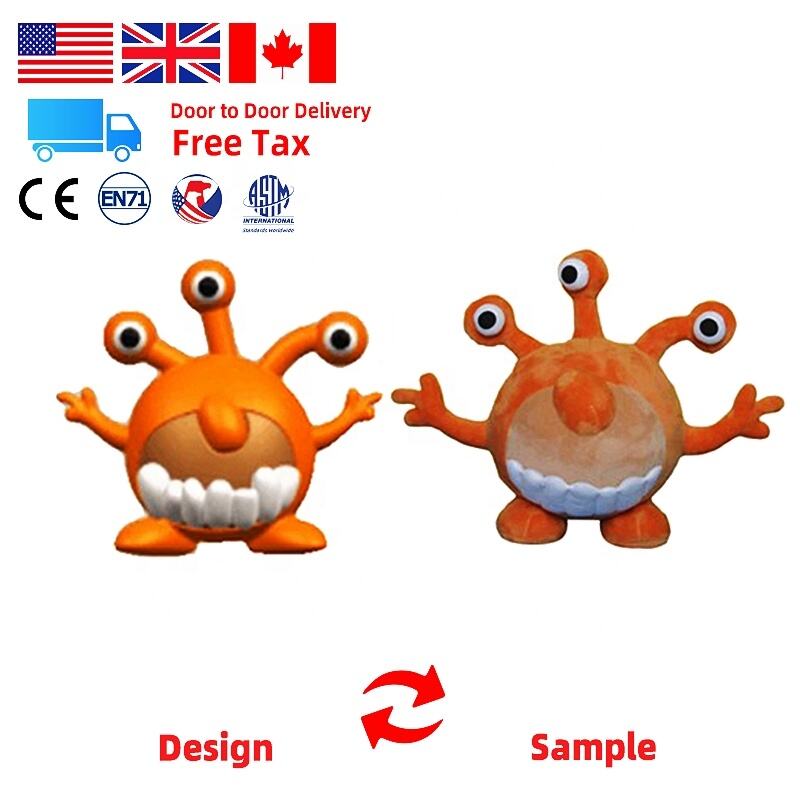

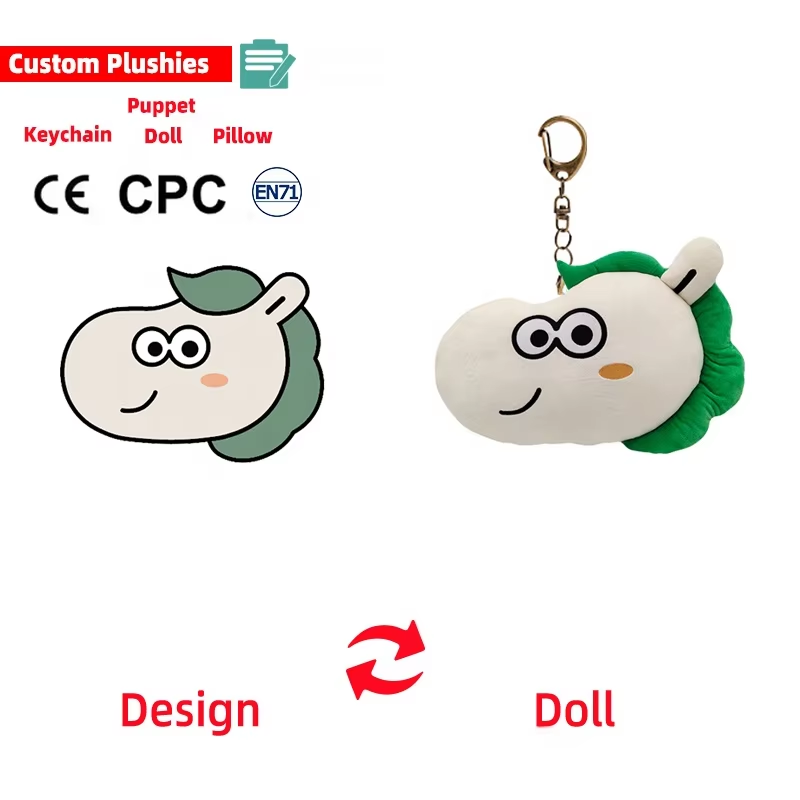

Орчин үеийн цугаалдаг тоглоомны машинтнуудын санал болгож буй захидалтын боломж нь аж бизнесүүд өвөрмөц, брэндчилсэн бүтээгдэхүүнүүдийг бий болгох, хэрэглэгчидтэй хувийн шинж чанараар нь холбогдох, зах зээлийн анхаарлыг татахад тусалдаг. Мэргэжлийн цугаалдаг тоглоомны үйлдвэрлэгчид нь брэндийн илэрхийлэлтэй танилцуулах, зорилтот бүлгийн сонирхлыг татаж чадахуйцаар санааг бодит бүтээгдэхүүн болгон хувиргахын тулд үйлчлүүлэгчтэй нягт хамтран ажилладаг ур чадвартай загварчлагчдын багтай ажилладаг. Эдгээр үйлдвэрлэгчид 3D загварчлалын програм хангамж, хурдан прототайп хийх тоног төхөөрөмж зэрэг дэвшилтэт технологи ашиглан үйлдвэрлэлийн бүрэн явцыг эхлэхээс өмнө үйлчлүүлэгчдэд загварыг харж, сайжруулах боломжийг олгодог нарийн загваруудыг бий болгодог. Захидалтын хүрээ нь хэмжээ, өнгөний схем, даавууны текстур, царайны илэрхийлэл, хувцас, хавтангууд, дууны модуль эсвэл интерактив элемент зэрэг функциональ онцлогууд гэх мэт бүтээгдэхүүний бүтээлч үйл явцын олон талыг хамардаг. Тоглоомны мэргэжлийн үйлдвэрлэгчид захидалт бүтээгдэхүүний хөгжүүлэлтийн төлөвийн дүр төрхийг бараг хязгааргүй болгодог даавуу, дүүргэгч материал, декоратив элементүүдийн өргөн сан байдаг. Үйлдвэрлэгчдийн техникийн мэдлэг нь загварын хийх боломжийг үнэлэх, үйлдвэрлэлийг хялбарчлах зорилгоор сайжруулах саналуудыг гаргах, загварын бүтэн байдлыг хадгалж, үйлдвэрлэлийн үр ашгийг дээшлүүлэхийн тулд зардал хэмнэх замуудыг санал болгоход тусалдаг. Мэргэжлийн цугаалдаг тоглоомны үйлдвэрлэгчдийн удирдсан хамтын ажиллагааны загвар нь үйлчлүүлэгчийн хүлээж баталсан хүрээнд хүрэх, төсөвлөсөн хугацаа болон төсөвт тохируулан шийдвэр гаргах, эцсийн бүтээгдэхүүн нь хүлээсээ давахуйц байдлыг хангах зорилгоор тогтмол холбоо харилцаа, загварын шинэчлэлт, баталгаажуулалтын үе шатуудыг хамардаг. Урьдчилан бодож хөгжүүлэлтийн инициативт хөрөнгө оруулдаг урьдчилан харъяа бодолтой цугаалдаг тоглоомны үйлдвэрлэгчдийн хамтын ажиллагаа нь материалын шинэ хэлбэр, үйлдвэрлэлийн арга технологи, функциональ онцлогуудыг судалж, бүтээгдэхүүний татамжийг нэмэгдүүлэх, зах зээл дээрх өрсөлдөх чадварыг дээшлүүлэх замаар шинэ санаа бүтээх боломжийг олгодог. Үйлдвэрлэгчдийн одоогийн зах зээлийн хандлага, хэрэглэгчийн сонирхол, улирлын эрэлт хэрэгцээг ойлгох чадвар нь загварын шийдвэрт үнэтэй ойлголтуудыг өгч, худалдааны хувьд хүчтэй боломжтой бүтээгдэхүүн бий болгоход тусалдаг. Тусгайчлагдсан цугаалдаг тоглоомны үйлдвэрлэгчдийн нэмэлт суулгац, хэвлэлтийн боломжууд нь товчлогдсон брендчлэл, нарийн зураглал, нарийн орчуулга зэрэгт ашиглагдаж, өрсөлдөх чадвартай худалдааны орчинд бүтээгдэхүүний найдвартай байдал, үнэ цэнийг нэмэгдүүлдэг.