animais de pelúcia a granel

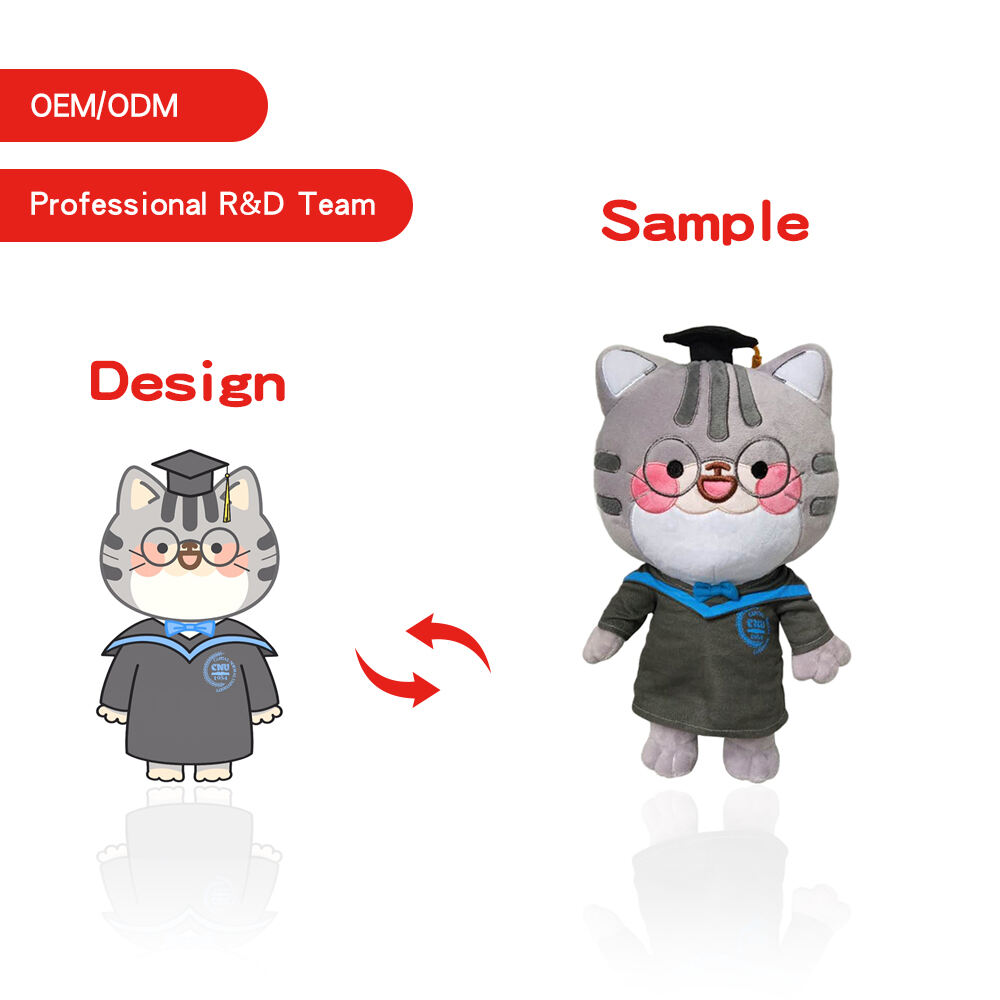

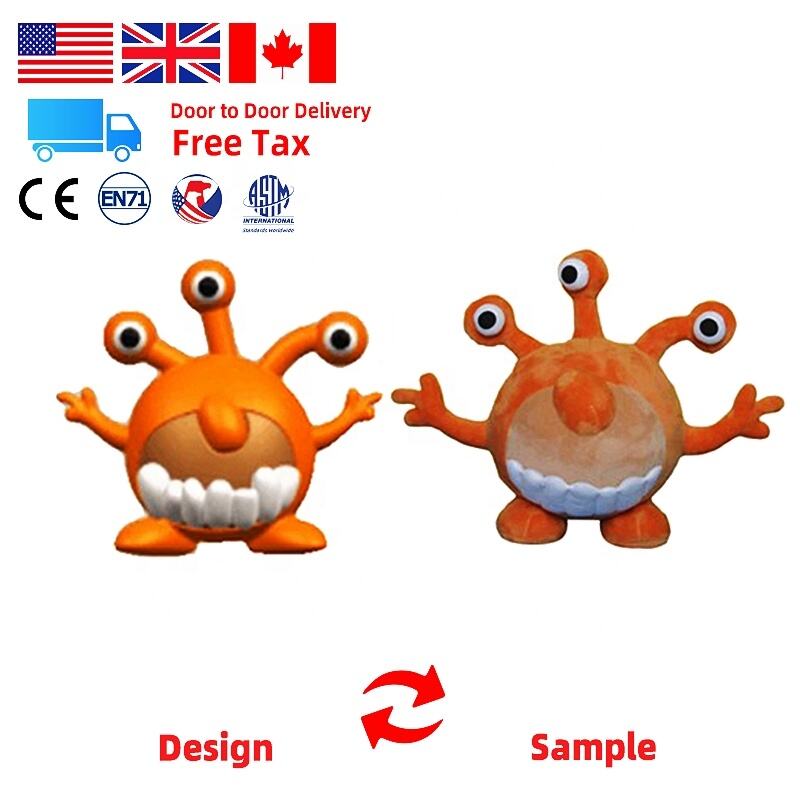

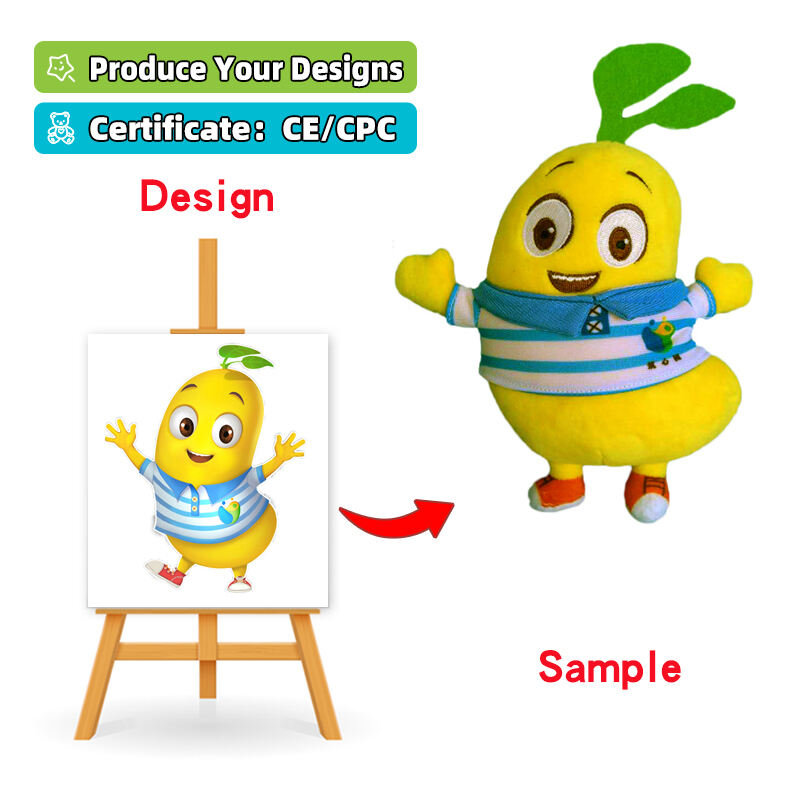

Brinquedos de pelúcia personalizados em grande quantidade representam uma solução abrangente de fabricação que transforma conceitos criativos em produtos de pelúcia de alta qualidade em larga escala. Esses serviços especializados de manufatura atendem empresas, organizações e empreendedores que desejam produzir brinquedos de pelúcia personalizados em grandes quantidades, mantendo padrões excepcionais de qualidade. O processo abrange consultoria completa de design, desenvolvimento de protótipos, seleção de materiais e capacidades de produção em larga escala, garantindo que cada pedido de brinquedos de pelúcia personalizados em grande quantidade atenda exatamente às especificações definidas. Instalações modernas de fabricação utilizam tecnologias têxteis avançadas, incluindo sistemas de bordado computadorizados, equipamentos de corte de precisão e protocolos de controle de qualidade que garantem resultados consistentes em toda a linha de produção. A estrutura tecnológica que sustenta a produção de brinquedos de pelúcia personalizados em grande quantidade inclui softwares sofisticados de design que permitem opções detalhadas de personalização, desde texturas e cores dos tecidos até detalhes intrincados como logotipos, mensagens e características exclusivas. As capacidades de produção normalmente acomodam pedidos que variam de centenas a milhares de unidades, tornando os brinquedos de pelúcia personalizados em grande quantidade uma solução ideal para campanhas promocionais, produtos para varejo, instituições educacionais e iniciativas de marca corporativa. Os processos de garantia de qualidade envolvem múltiplas etapas de inspeção, assegurando durabilidade, conformidade com normas de segurança e apelo visual durante todo o ciclo de fabricação. As aplicações abrangem diversos setores, incluindo entretenimento, saúde, educação, varejo e corporativo, onde os brinquedos de pelúcia personalizados em grande quantidade atuam como ferramentas eficazes de marketing, auxiliares educacionais, companheiros terapêuticos e presentes memoráveis que criam conexões emocionais duradouras com os públicos-alvo.