ผลิตภัณฑ์เสริมอื่น ๆ ที่สามารถพัฒนาสำหรับลูกค้าองค์กรได้นอกเหนือจากตุ๊กตานามสกุลคืออะไร

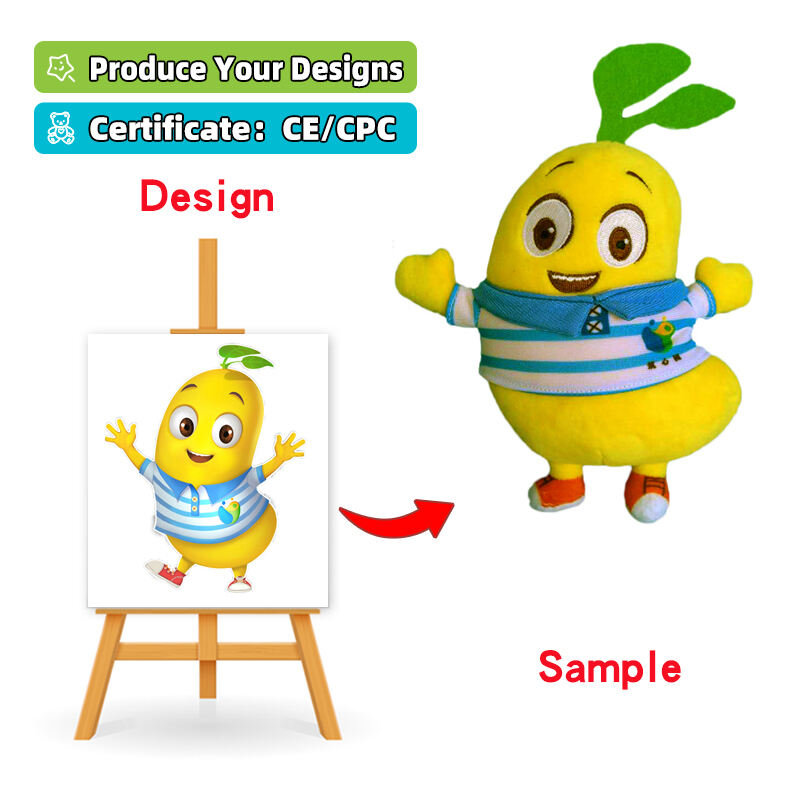

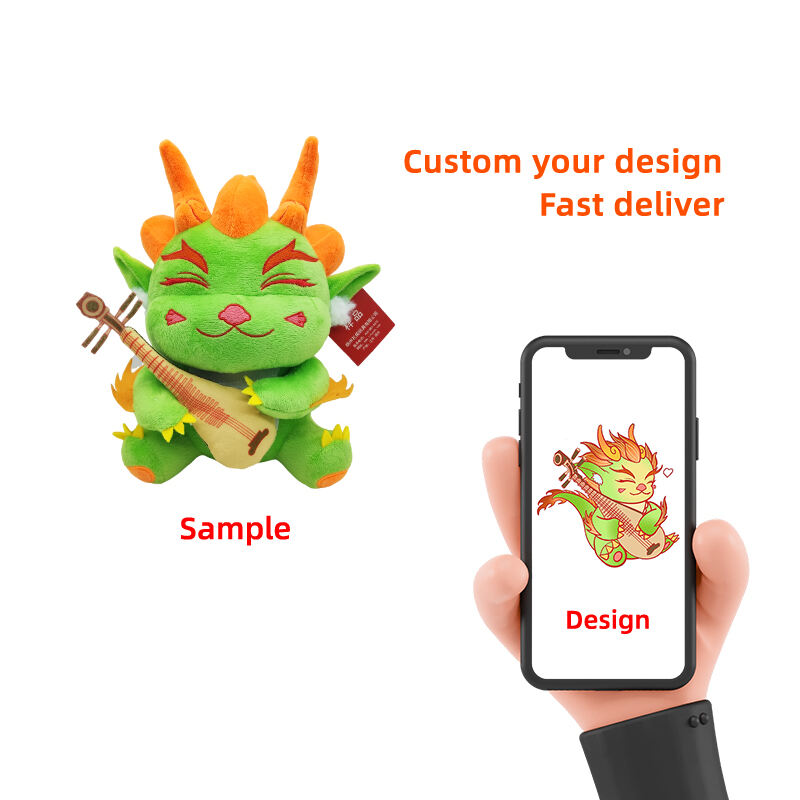

ตัวการ์ตูนแบรนด์ที่โดดเด่นนั้นมากกว่าเพียงแค่ภาพลักษณ์ที่น่ารักหรือของเล่นผ้ากำมะหยี่ชิ้นเดียว—มันควรจะถ่ายทอดจิตวิญญาณของแบรนด์ และทำหน้าที่เป็นสะพานเชื่อมโยงทางอารมณ์ระหว่างบริษัทกับกลุ่มเป้าหมาย โดยการสร้างสรรค์ผลิตภัณฑ์เสริมหลากหลายรูปแบบ

ดูเพิ่มเติม