tagagawa ng plush toys

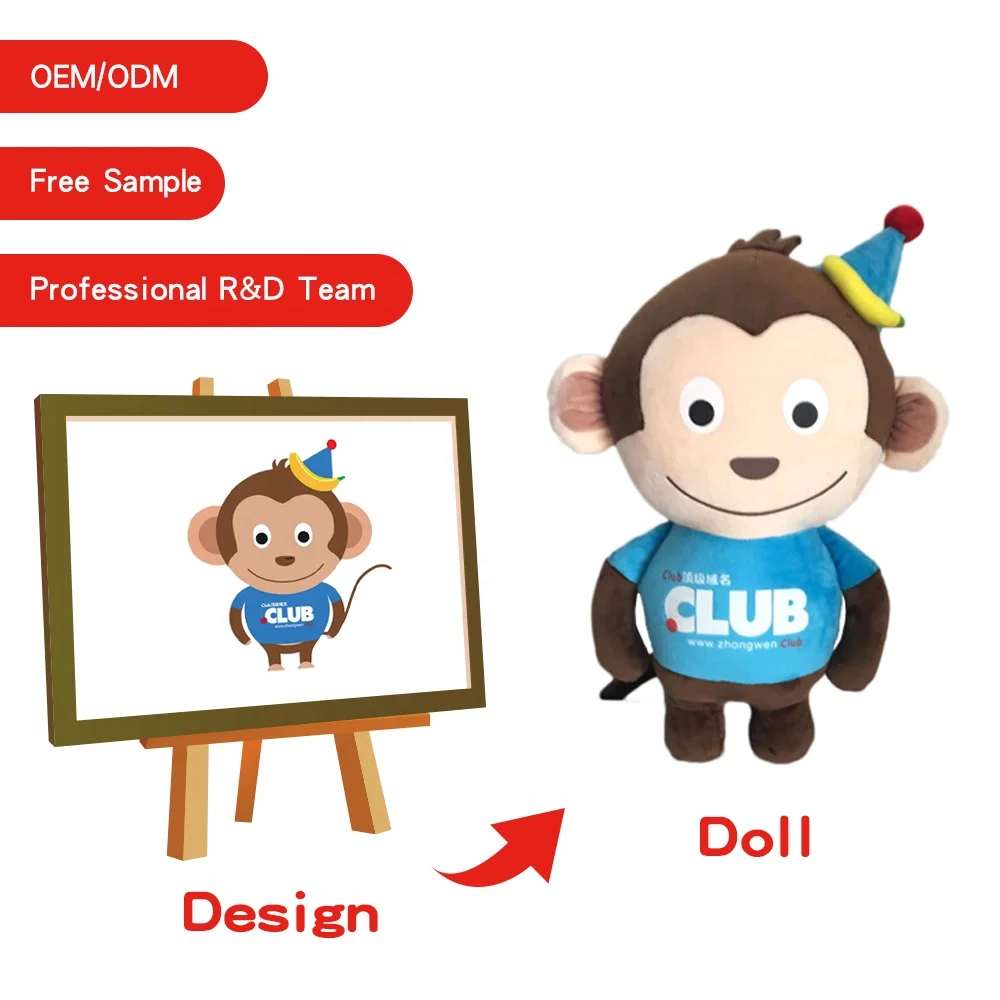

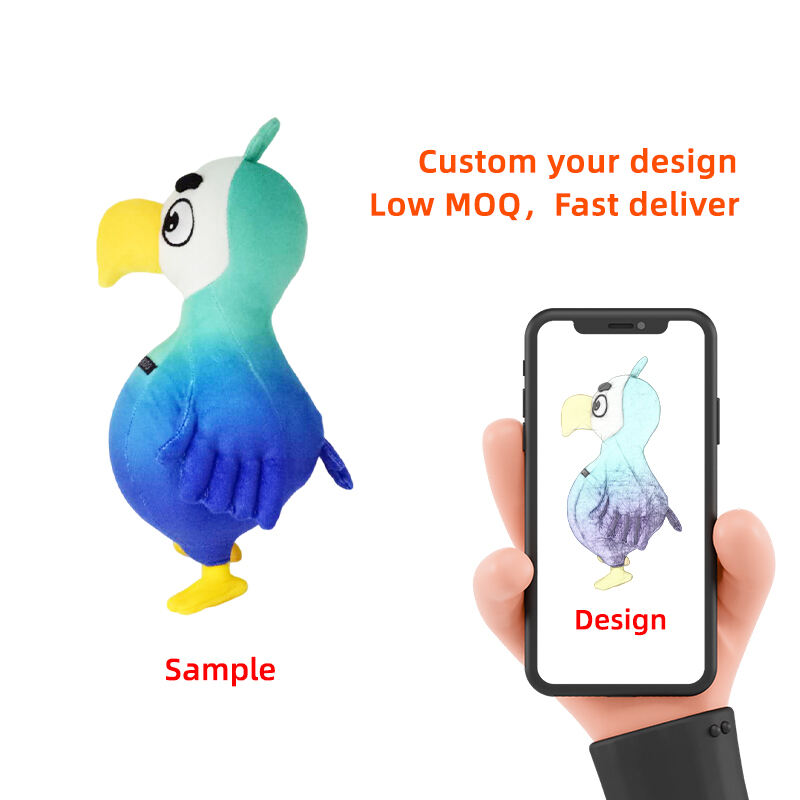

Ang isang tagagawa ng plush toys ay kumakatawan sa isang espesyalisadong pasilidad sa produksyon na nagdidisenyo, gumagawa, at nagpapamahagi ng mga malambot na stuffed toy para sa iba't ibang merkado sa buong mundo. Pinagsasama ng mga kumpanyang ito ang tradisyonal na kasanayan sa paggawa at modernong teknolohiya upang makalikha ng mga plush product na may mataas na kalidad at sumusunod sa mga pamantayan ng kaligtasan at inaasahan ng mga konsyumer. Ang pangunahing tungkulin ng isang tagagawa ng plush toys ay ang pagbabago sa mga hilaw na materyales tulad ng synthetic fibers, cotton, polyester filling, at tela upang maging tapos na produkto sa pamamagitan ng sopistikadong proseso ng produksyon. Kasama sa mga pasilidad na ito ang komprehensibong linya ng produksyon na binubuo ng disenyo ng pattern, pagputol, pananahi, pagpupuno, kontrol sa kalidad, at mga departamento sa pag-iimpake. Isinasama ng modernong operasyon ng tagagawa ng plush toys ang mga advanced na makina tulad ng computerized embroidery machines, automated cutting systems, at precision sewing equipment upang matiyak ang pare-parehong kalidad ng produkto at epektibong daloy ng produksyon. Kasama sa mga teknolohikal na tampok ng kasalukuyang mga pasilidad ng tagagawa ng plush toys ang digital design software para sa paglikha ng detalyadong technical specifications, automated inventory management systems, at quality assurance protocols na tinitiyak ang pagsunod sa internasyonal na mga regulasyon sa kaligtasan. Tinataglay ng mga tagagawa na ito ang maraming aplikasyon sa iba't ibang sektor kabilang ang retail toy stores, mga kumpanya ng promotional merchandise, entertainment franchises, institusyong pang-edukasyon, at mga pasilidad sa healthcare. Ang versatility ng isang tagagawa ng plush toys ay nagbibigay-daan sa custom production runs, private label manufacturing, at specialized product development upang matugunan ang tiyak na pangangailangan ng mga kliyente. Nag-aalok din ang maraming pasilidad ng karagdagang serbisyo tulad ng packaging ng produkto, paglalagay ng label, at direktang pagpapadala sa mga huling kustomer. Ang proseso ng pagmamanupaktura ay karaniwang nagsisimula sa pagbuo ng konsepto at pag-apruba sa disenyo, sinusundan ng pagkuha ng materyales, paglikha ng prototype, at mass production. Isinasama ang mga hakbang sa kontrol ng kalidad sa buong siklo ng produksyon upang matiyak na ang bawat plush toy ay sumusunod sa itinakdang mga pamantayan ng kaligtasan at kinakailangan sa katatagan. Pinananatili ng isang propesyonal na tagagawa ng plush toys ang mga sertipikasyon mula sa mga kaugnay na regulatory bodies at ipinapatupad ang mga sustainable manufacturing practices upang bawasan ang epekto sa kapaligiran habang pinapataas ang kahusayan ng produksyon at kalidad ng produkto.