custom plush com

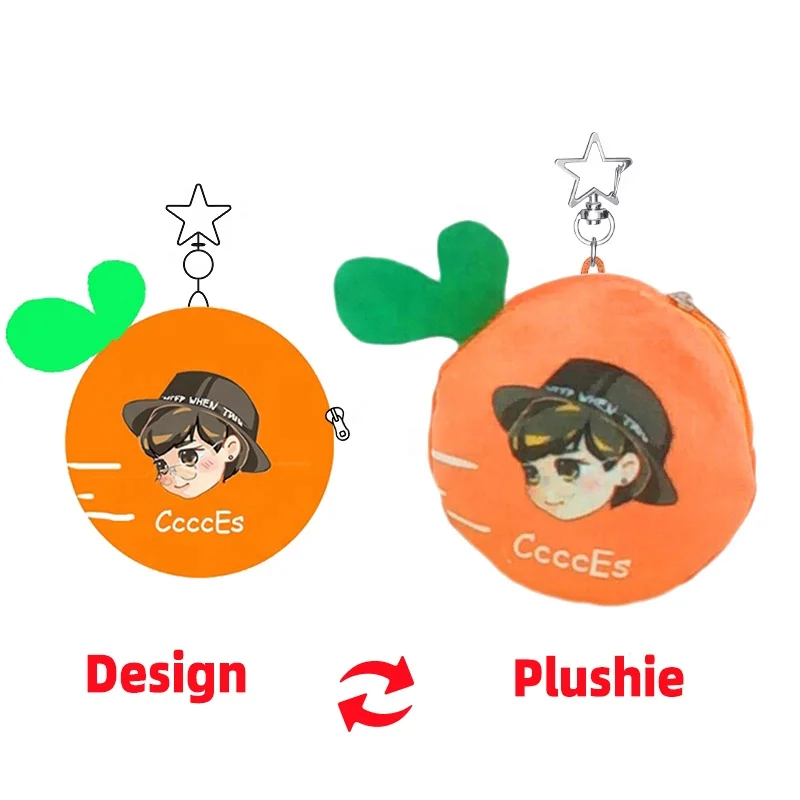

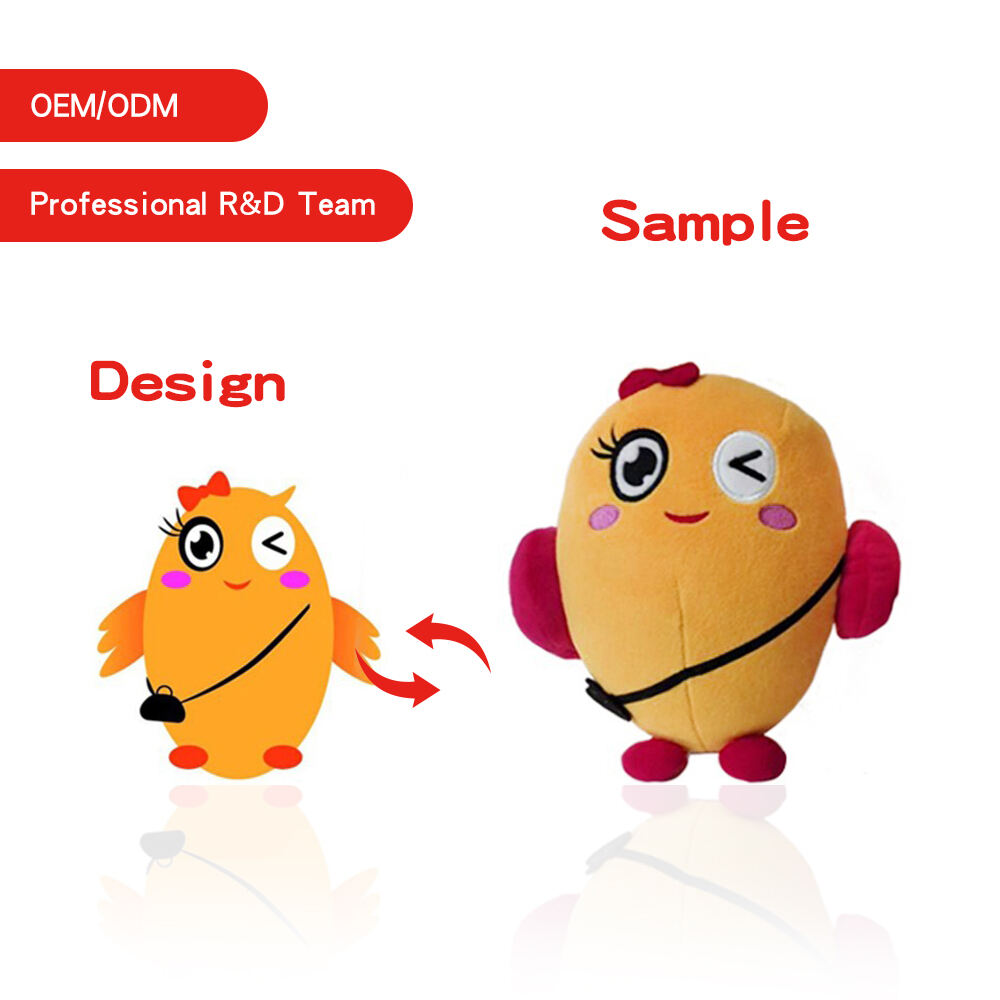

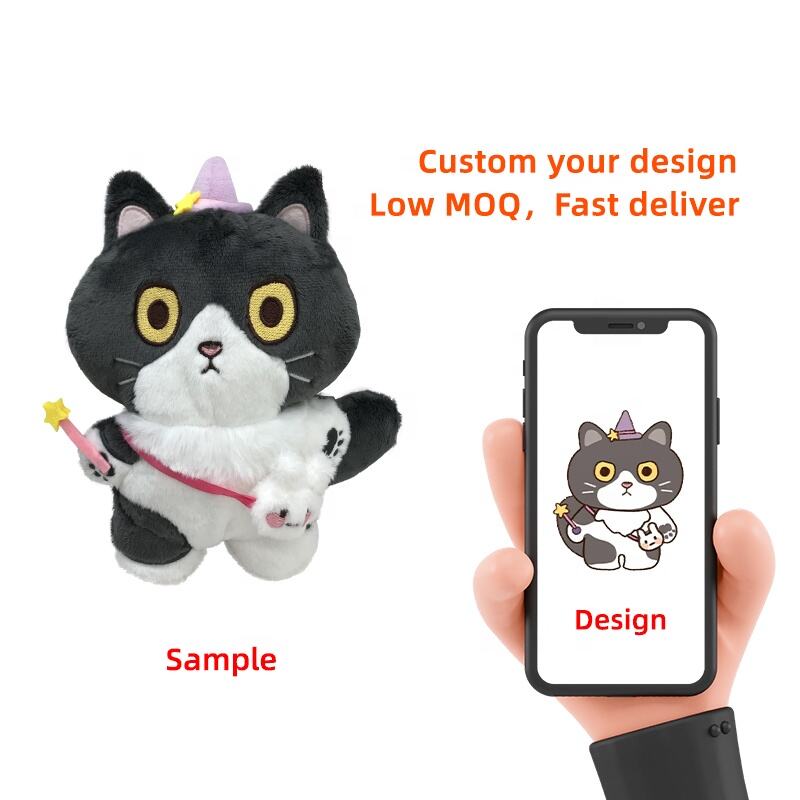

Custom plush com represents a revolutionary approach to personalized soft toy manufacturing that combines advanced digital design capabilities with traditional craftsmanship to create unique, high-quality plush products. This comprehensive platform serves as a bridge between creative vision and tangible reality, enabling individuals, businesses, and organizations to bring their imaginative concepts to life through custom-designed stuffed animals, mascots, and collectible items. The system integrates cutting-edge 3D modeling technology with sophisticated manufacturing processes to ensure precision in every detail of the final product. At its core, custom plush com operates through an intuitive interface that allows users to specify dimensions, colors, textures, and intricate design elements with remarkable accuracy. The platform supports various material options including premium cotton, polyester blends, and eco-friendly alternatives, catering to diverse preferences and sustainability requirements. Advanced pattern-making algorithms automatically generate production templates based on user specifications, while quality assurance protocols guarantee consistency across multiple units. The technological infrastructure incorporates machine learning capabilities that optimize design elements for manufacturability, reducing production time while maintaining exceptional quality standards. Applications span multiple industries including entertainment, education, marketing, and personal gifting, with successful implementations ranging from corporate mascots and promotional items to therapeutic aids and educational tools. The system's versatility extends to accommodate both small-scale individual orders and large commercial productions, making it accessible to entrepreneurs, established businesses, and creative professionals alike. Integration capabilities allow seamless connection with existing e-commerce platforms and inventory management systems, streamlining the entire production workflow from initial concept to final delivery.