Comprehensive Quality Control and Safety Compliance Systems

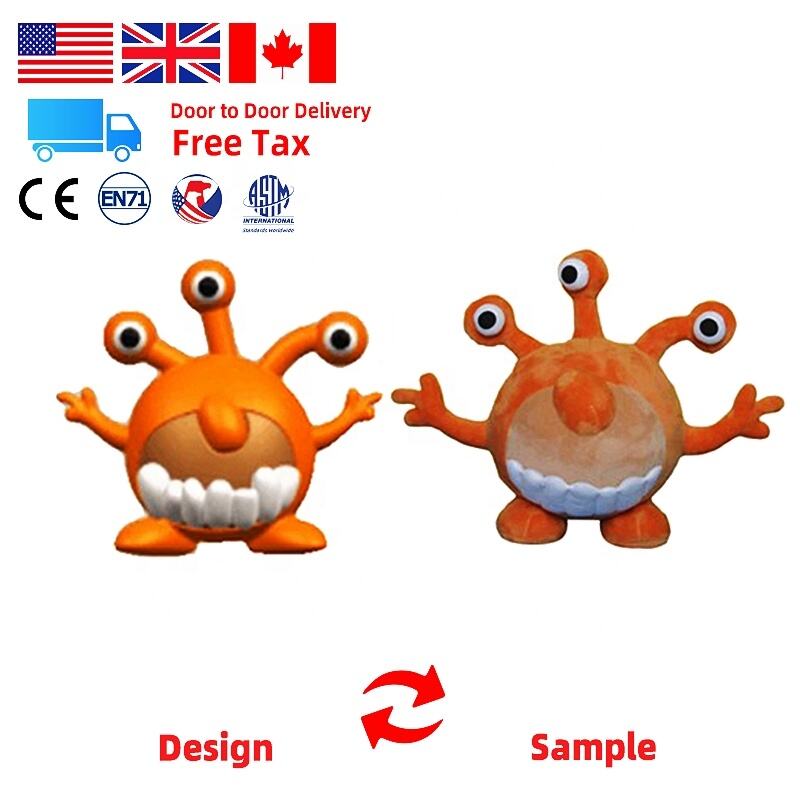

The comprehensive quality control and safety compliance systems implemented by professional custom plush manufacturer facilities represent critical differentiators that protect customers, end users, and brand reputations through rigorous testing protocols and adherence to international safety standards. Multi-stage inspection processes begin with incoming material verification, where every fabric shipment undergoes testing for colorfastness, tensile strength, and chemical composition to ensure compliance with safety regulations such as CPSIA, EN71, and ASTM standards. Trained quality assurance technicians conduct thorough examinations at each production milestone, monitoring stitching integrity, stuffing distribution, and component attachment security using standardized checklists and measurement tools. Advanced testing equipment measures pull strength for small parts, verifies flame resistance properties, and analyzes material composition for restricted substances that could pose health risks to users. The custom plush manufacturer quality control framework includes batch sampling procedures that statistically validate production consistency across large order volumes, ensuring that quality standards remain uniform regardless of order size or production timeline pressures. Documentation systems maintain detailed records of all testing results, material certifications, and production parameters, providing complete traceability for regulatory compliance and potential recall situations. Laboratory partnerships enable access to specialized testing capabilities for specific requirements such as antimicrobial properties, allergen testing, and environmental impact assessments. Continuous improvement protocols analyze quality metrics, customer feedback, and industry best practices to refine testing procedures and enhance overall product reliability. The safety compliance expertise of established custom plush manufacturer operations extends beyond basic requirements to anticipate emerging regulations and market trends, protecting customers from potential liability issues and ensuring products remain compliant throughout their market lifecycle. Final inspection procedures include comprehensive functionality testing, packaging integrity verification, and random sampling for third-party validation when required by specific market segments or customer policies. This unwavering commitment to quality control and safety compliance provides customers with confidence in their products while minimizing risks associated with manufacturing defects or regulatory non-compliance issues.