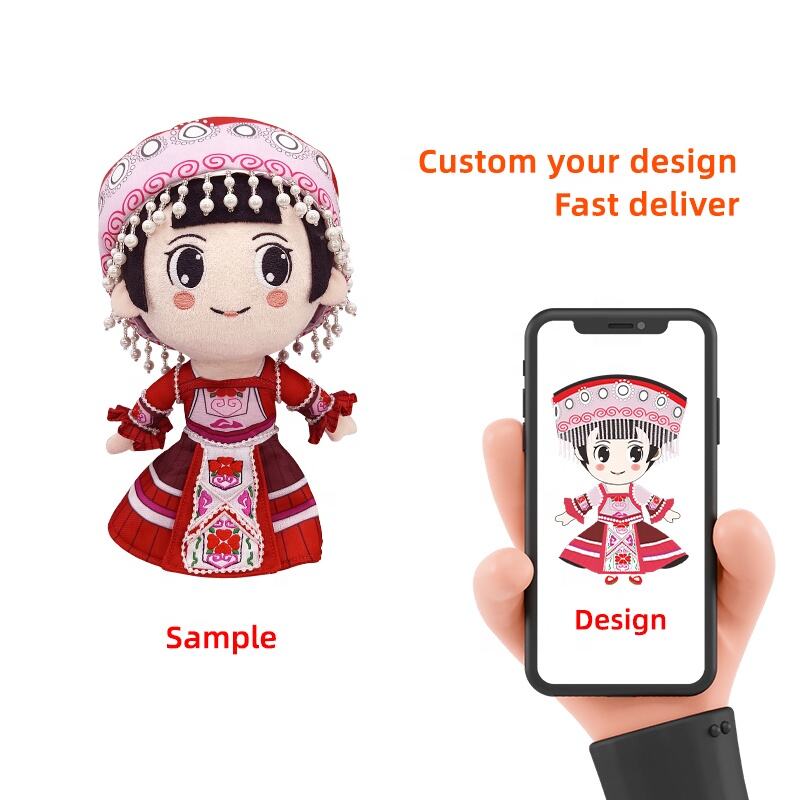

Comprehensive Customization and Personalization Options

The extensive customization capabilities available when choosing to make drawings into plushies set this service apart from standard toy manufacturing by offering unprecedented personalization options that honor individual artistic vision while enhancing functionality and appeal. Size customization ranges from miniature versions suitable for keychains or desk accessories measuring just three inches, to large companion-sized plushies exceeding two feet in height, with precise scaling algorithms ensuring proportional accuracy across all size variations. Fabric selection encompasses over fifty different textures and materials, including traditional plush fabrics, corduroy, fleece, minky, and specialized options like glow-in-the-dark or color-changing materials that add interactive elements to the finished product. Customers can specify different fabric types for different areas of their plushie, creating tactile variety that enhances sensory engagement and visual interest. Embroidery customization allows for intricate detail reproduction using high-end computerized embroidery machines capable of creating complex patterns, text, and fine details that might be challenging to achieve through traditional fabric application methods. Sound module integration offers the option to include voice recordings, music, or sound effects activated through gentle pressure, enabling plushies to speak phrases, sing songs, or produce sounds that relate to the original character design. Accessory options extend personalization further through removable clothing items, hats, glasses, or other props that can be crafted to match elements shown in the original drawing, creating a complete character representation that captures every detail of the artistic vision. Fill material choices range from traditional polyester fiberfill to memory foam inserts, weighted beads for sensory applications, or organic cotton alternatives for customers preferring natural materials. Surface treatment options include protective coatings that make plushies easier to clean, antimicrobial treatments for enhanced hygiene, or flame-retardant applications for enhanced safety compliance. The customization process includes collaborative design consultation where professional designers work directly with customers to optimize their artwork for plushie format while maintaining creative integrity and ensuring manufacturing feasibility. Multiple revision rounds ensure complete customer satisfaction before production begins, with digital mockups and physical samples available for complex projects requiring additional validation.