custom plush toys bulk

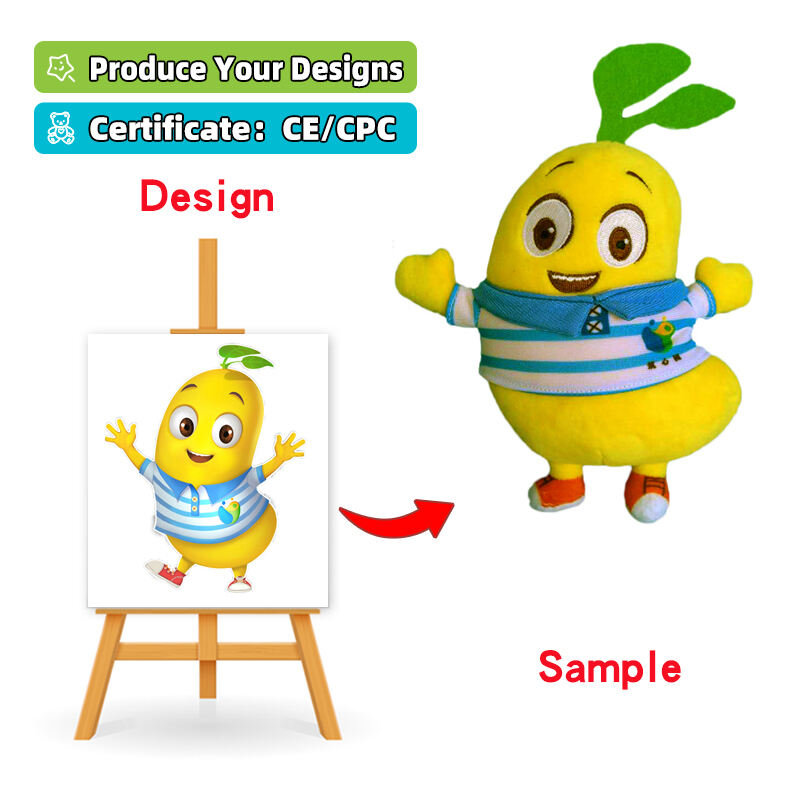

Custom plush toys bulk manufacturing represents a comprehensive solution for businesses, organizations, and entrepreneurs seeking to create personalized soft toys at scale. This specialized service combines advanced textile engineering with creative design capabilities to produce high-quality stuffed animals, mascots, and decorative plushies tailored to specific requirements. The bulk production approach leverages economies of scale, enabling significant cost reductions while maintaining exceptional quality standards across large quantities. Modern custom plush toys bulk operations utilize cutting-edge CAD software for precise pattern development, ensuring consistent dimensions and proportions throughout production runs. The manufacturing process incorporates premium materials including hypoallergenic polyester fiberfill, durable cotton fabrics, and specialized safety-tested components that meet international toy safety regulations. Advanced embroidery machines and heat-transfer technologies enable intricate logo placement, detailed facial features, and complex color patterns with remarkable precision. Quality control systems monitor every production stage, from initial material inspection through final packaging, guaranteeing that each plush toy meets rigorous standards. The technological infrastructure supporting custom plush toys bulk production includes automated cutting systems that optimize fabric usage, reducing waste by up to thirty percent compared to traditional methods. Digital color matching ensures brand consistency across entire product lines, while specialized sewing equipment handles various textures and materials seamlessly. Applications span diverse industries including corporate marketing campaigns, educational institutions creating mascots, entertainment companies developing merchandise, healthcare facilities producing therapeutic toys, and retail brands launching exclusive product lines. The versatility of custom plush toys bulk makes them ideal for promotional giveaways, fundraising initiatives, anniversary celebrations, and seasonal marketing campaigns, providing tangible brand representation that resonates with audiences across all demographics.