Advanced Design Capabilities and Personalization Options

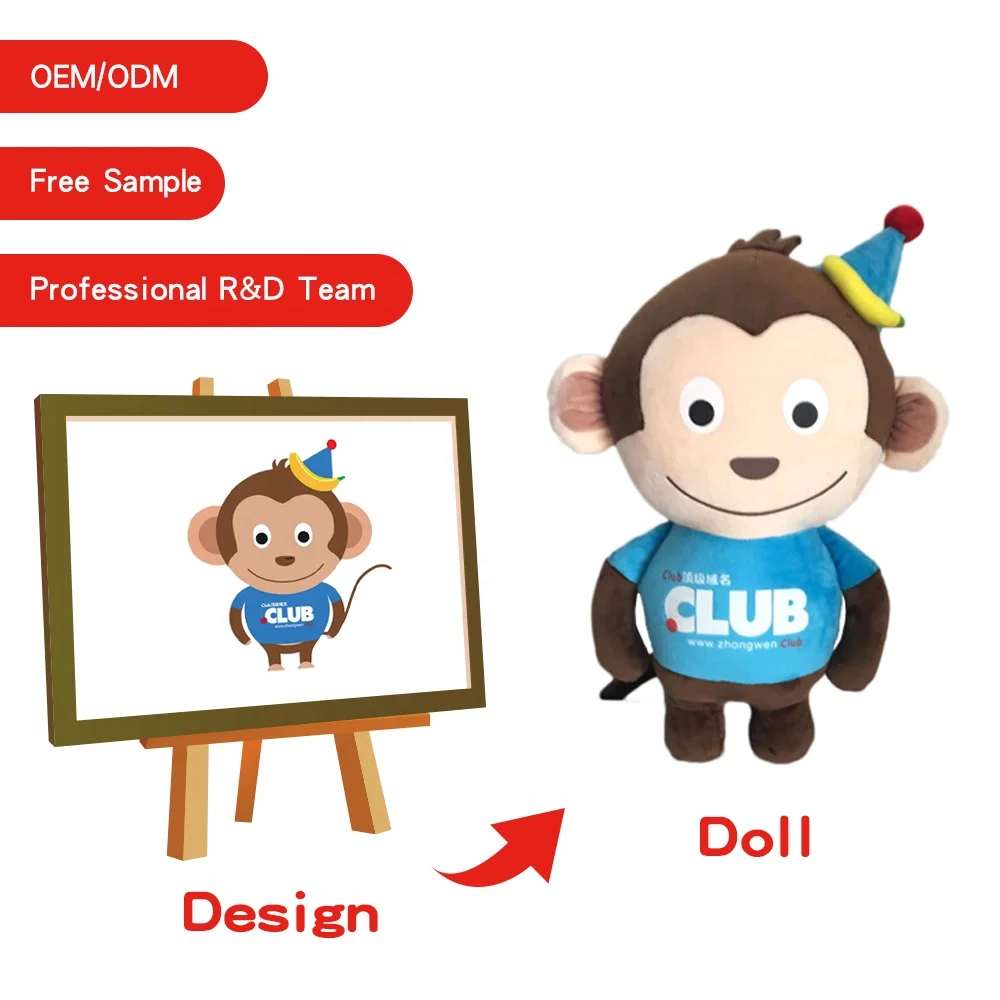

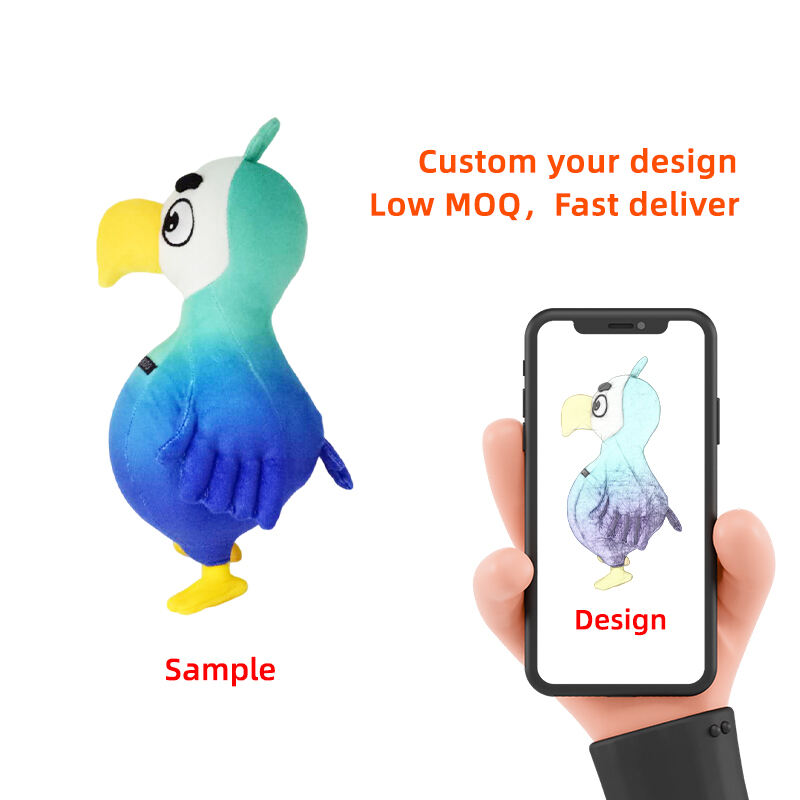

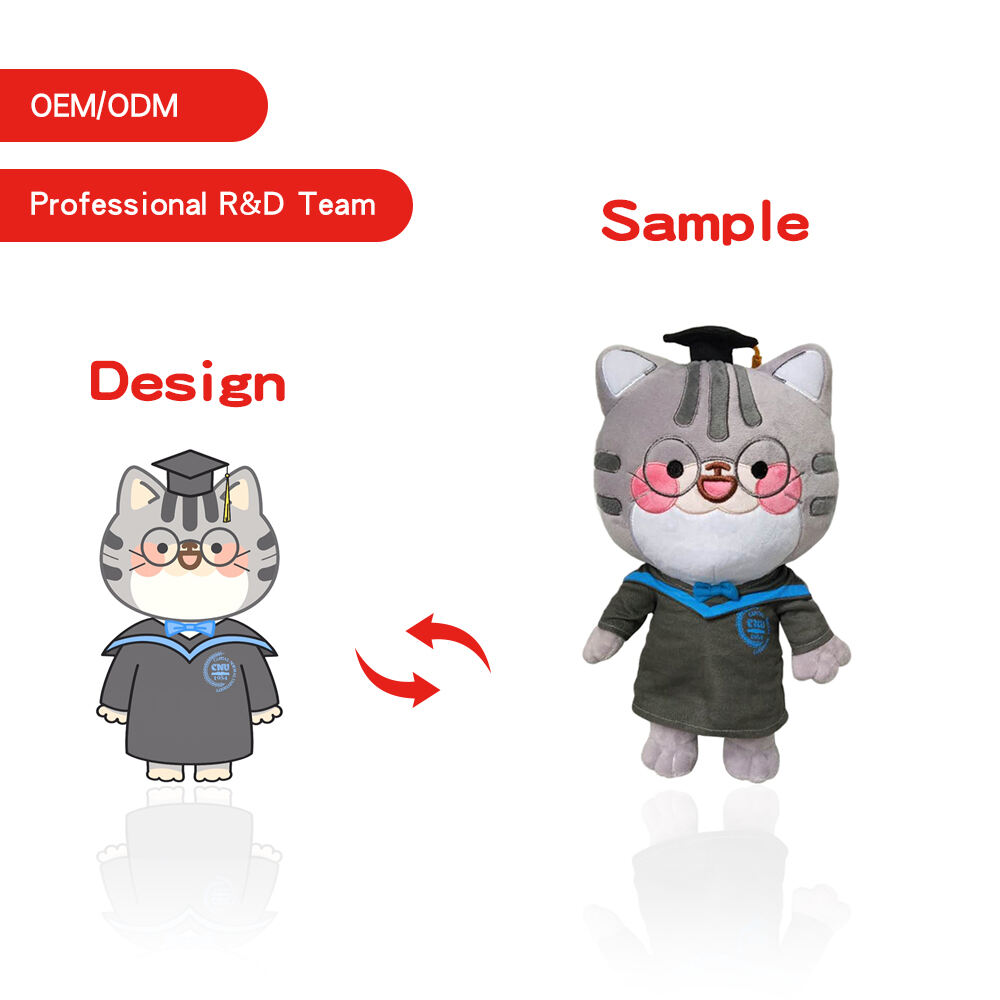

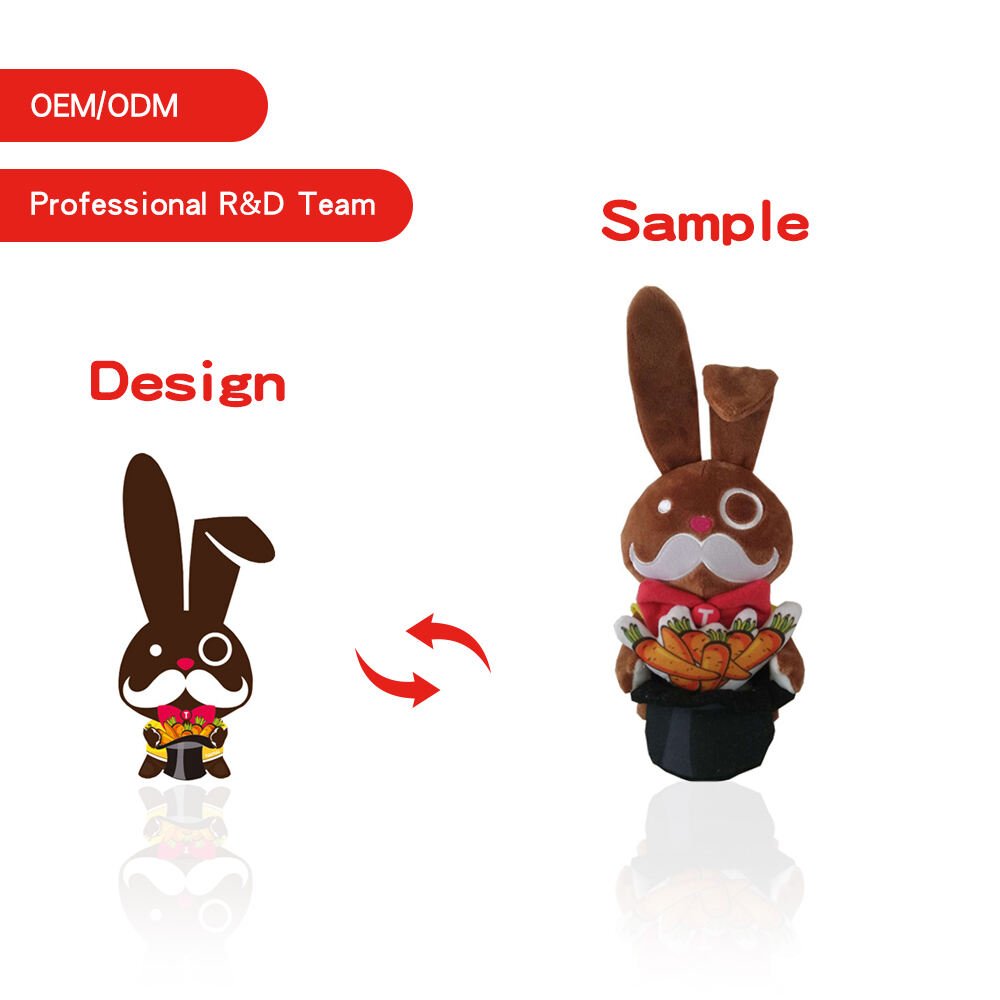

Custom stuffed animal manufacturers excel in providing comprehensive design capabilities that transform abstract concepts into detailed, manufacturable products through sophisticated design processes and personalization options. These manufacturers utilize state-of-the-art computer-aided design software that allows for precise pattern creation, three-dimensional modeling, and virtual prototyping before physical production begins. The design teams work collaboratively with clients to interpret their vision, whether it involves recreating existing characters, developing original mascots, or creating therapeutic comfort items with specific functional requirements. The personalization options offered by professional custom stuffed animal manufacturers extend far beyond basic color and size modifications, encompassing intricate details such as facial expressions, body proportions, accessory integration, and specialized features like sound modules or removable components. These manufacturers maintain extensive libraries of fabric options, including various textures, patterns, and specialized materials such as hypoallergenic options for sensitive users or flame-retardant materials for institutional applications. The advanced embroidery and printing capabilities enable manufacturers to add logos, text, or complex graphics with exceptional precision and durability. Many custom stuffed animal manufacturers also offer interactive features such as recorded voice messages, LED lighting, or motion sensors that enhance the final product's appeal and functionality. The importance of these advanced design capabilities lies in their ability to create products that perfectly align with client objectives, whether for marketing campaigns, therapeutic applications, or retail merchandise. The value to potential customers includes reduced development time, professional design expertise, and access to manufacturing techniques that would be cost-prohibitive for individual projects. These comprehensive design services ensure that every custom stuffed animal meets exact specifications while maintaining production feasibility and cost-effectiveness, ultimately delivering products that exceed client expectations and serve their intended purposes effectively.