plush animal manufacturers

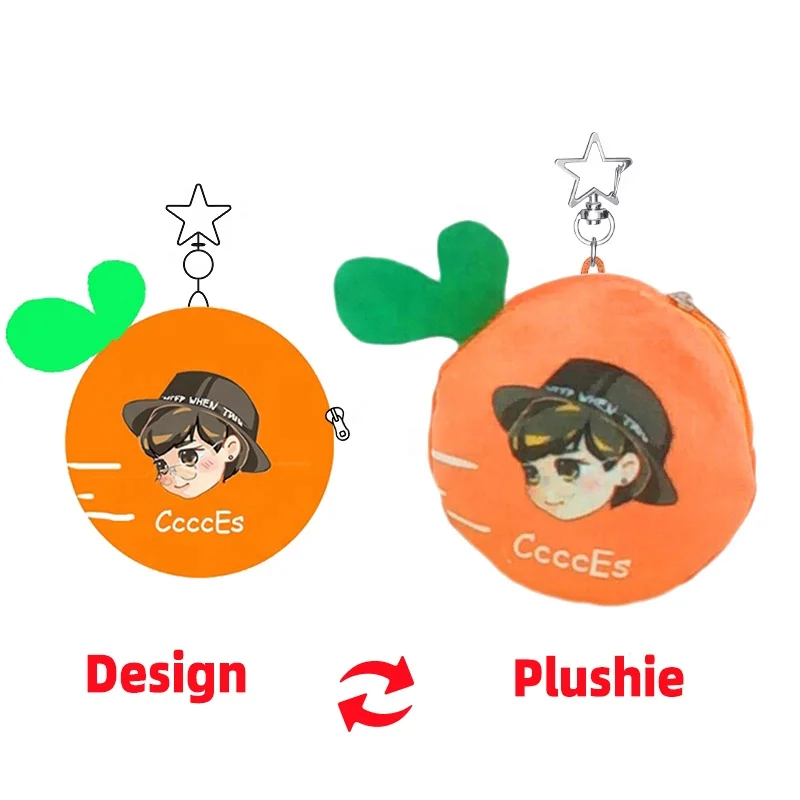

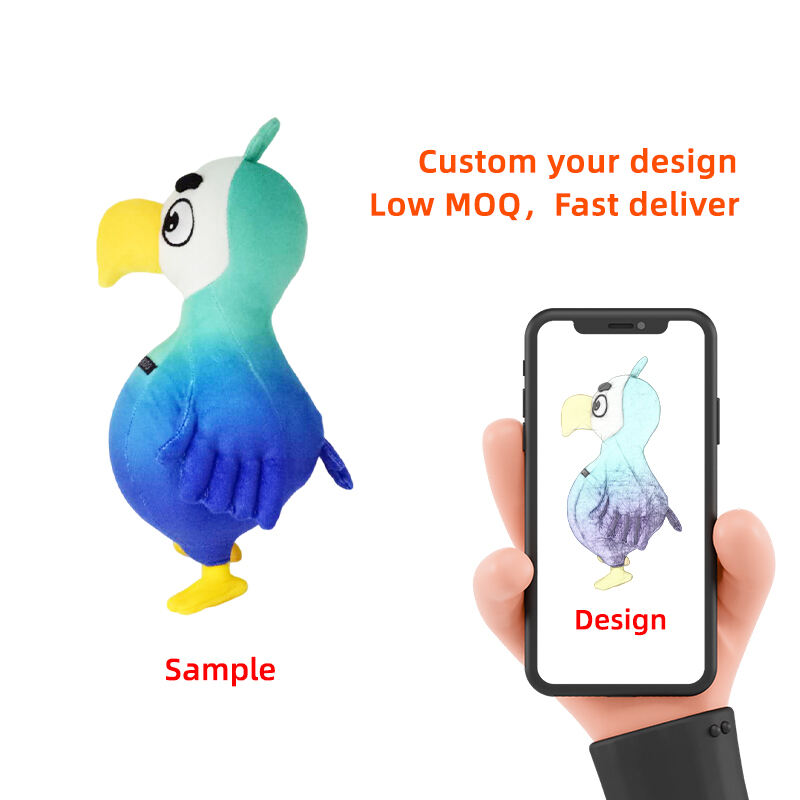

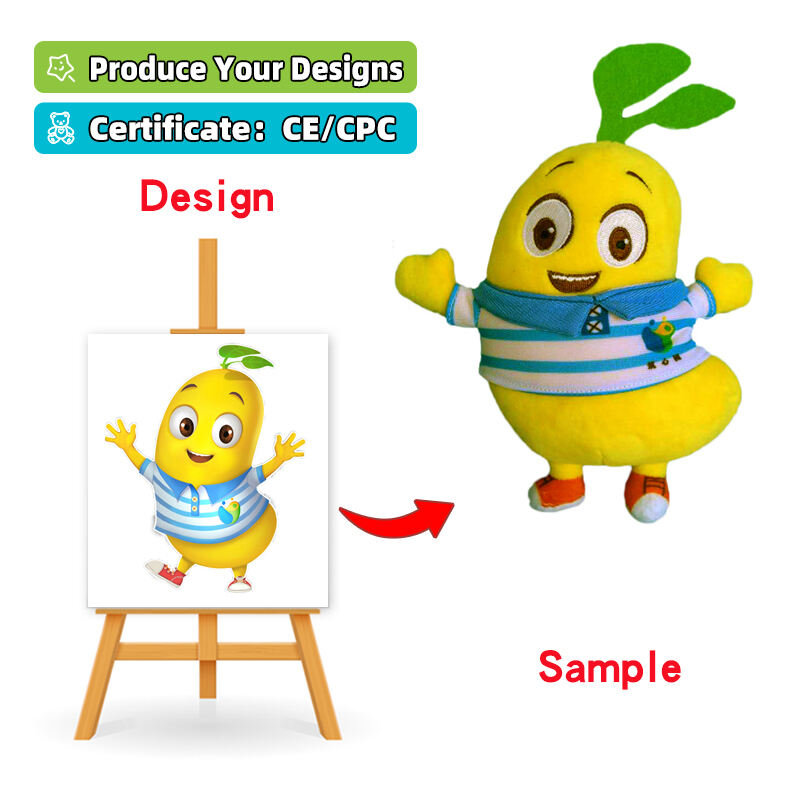

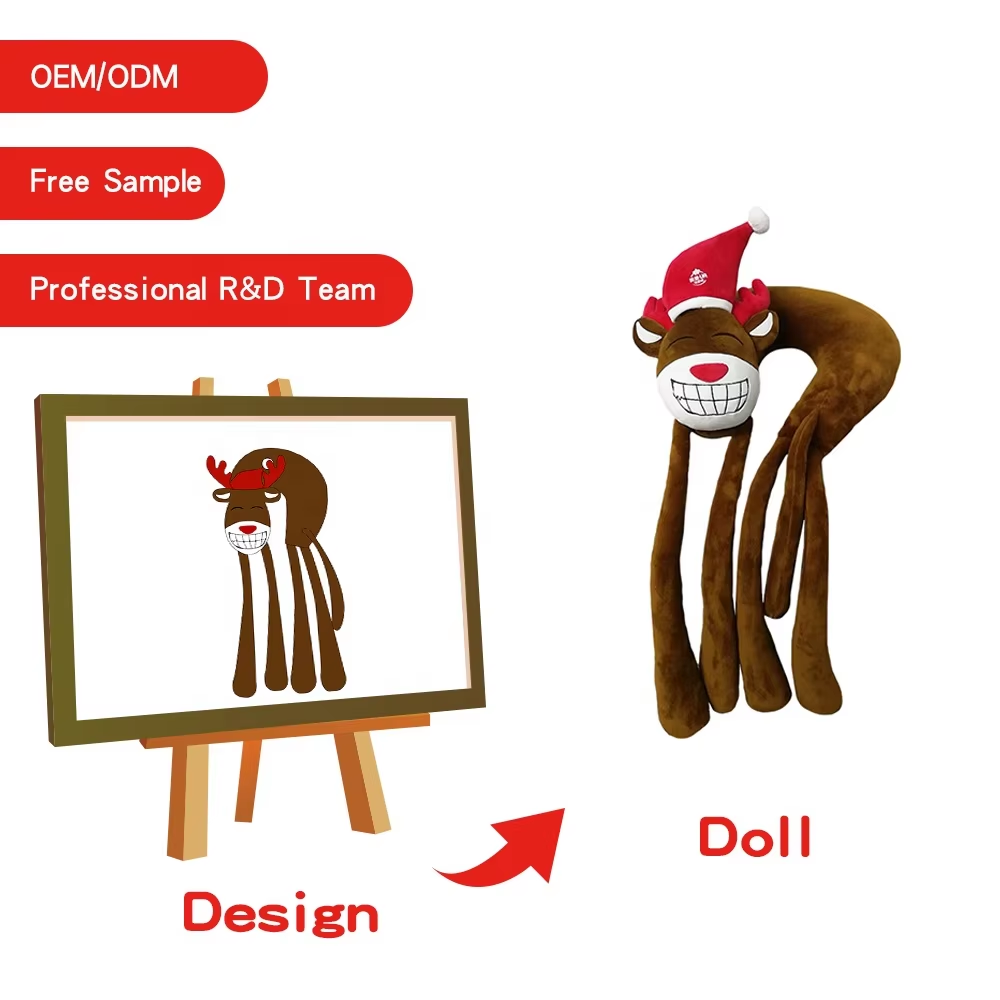

Plush animal manufacturers represent a specialized sector within the global toy industry, dedicated to creating soft, cuddly stuffed animals that bring joy to children and adults alike. These companies combine traditional craftsmanship with modern production techniques to deliver high-quality plush toys that meet stringent safety standards and customer expectations. The primary function of plush animal manufacturers involves designing, producing, and distributing a wide range of stuffed animals, from classic teddy bears to exotic wildlife replicas and popular character-based toys. These manufacturers utilize advanced textile technologies, including computerized embroidery systems, precision cutting equipment, and automated stuffing machinery to ensure consistent product quality and efficient production cycles. Modern plush animal manufacturers incorporate sustainable materials such as recycled polyester filling, organic cotton fabrics, and eco-friendly dyes to meet growing environmental consciousness among consumers. Their technological features include sophisticated quality control systems that monitor fabric durability, stitching integrity, and safety compliance throughout the manufacturing process. Many facilities employ digital design software that allows for precise pattern creation and color matching, ensuring brand consistency across large production runs. The applications of plush animal manufacturers extend far beyond traditional toy retail, encompassing promotional merchandise, therapeutic tools for healthcare facilities, educational resources for schools, and collectible items for enthusiasts. These manufacturers serve diverse markets including major toy retailers, specialty gift shops, theme parks, entertainment companies, and corporate clients seeking branded promotional items. Their production capabilities range from small custom orders to massive international distribution contracts, with many facilities offering private labeling services and custom design consultation. The industry continues to evolve with technological advancements in materials science, automation, and sustainable manufacturing practices, positioning plush animal manufacturers as innovative partners in the broader consumer goods ecosystem.