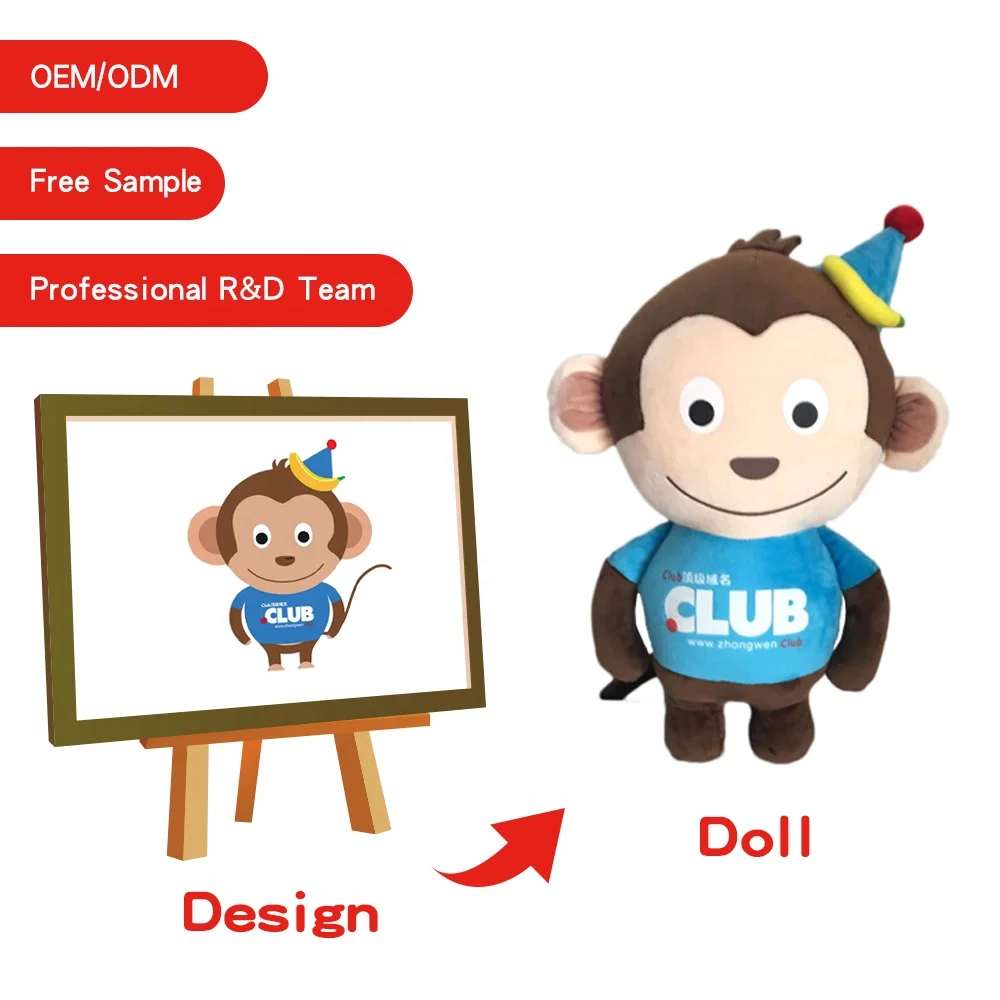

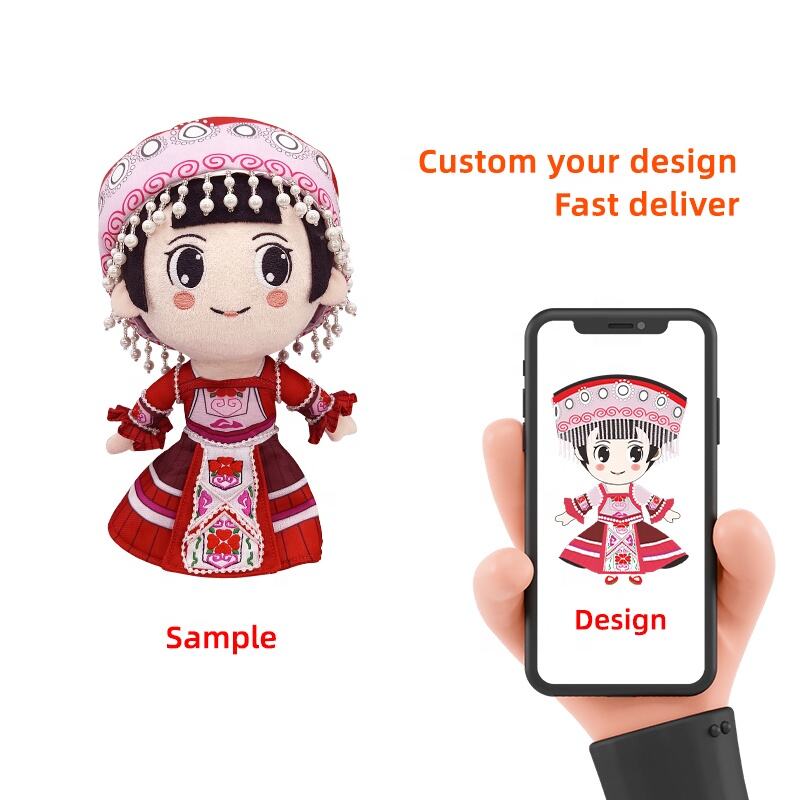

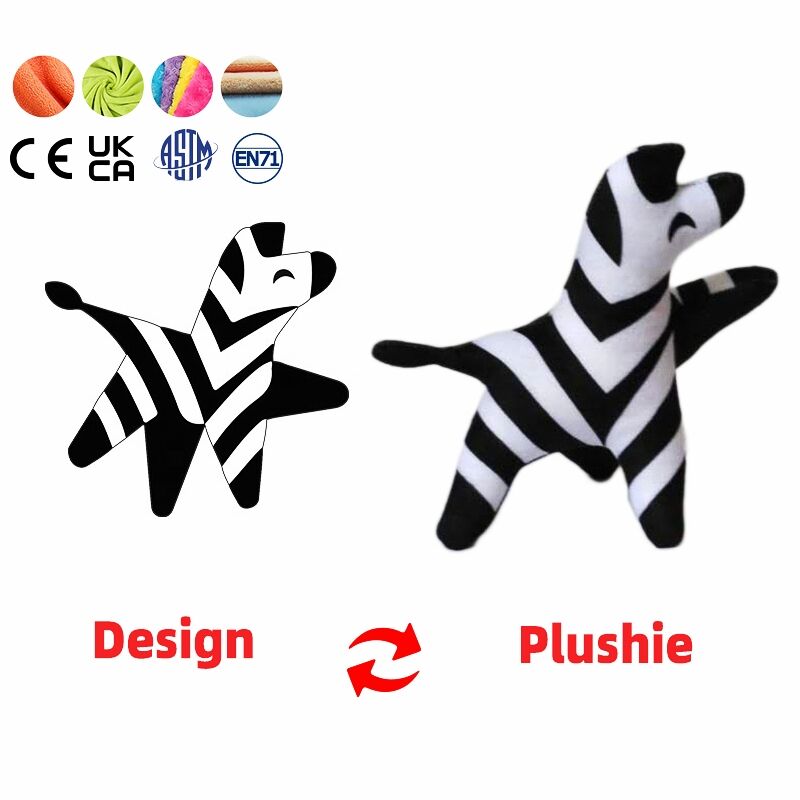

plush custom design

Plush custom design represents a revolutionary approach to creating personalized soft toys and fabric products that meet specific customer requirements and brand specifications. This innovative manufacturing process combines traditional craftsmanship with modern production techniques to deliver unique, high-quality plush items tailored to individual needs. The main functions of plush custom design encompass comprehensive product development from initial concept sketches to final production, including character creation, brand mascot development, promotional merchandise, and specialized therapeutic toys. The technological features of plush custom design incorporate advanced fabric selection processes, precision cutting systems, computerized embroidery capabilities, and quality control mechanisms that ensure consistent results across production runs. Modern plush custom design utilizes digital pattern creation software, automated cutting machines, and specialized sewing equipment to achieve precise dimensions and intricate details. The applications of plush custom design span multiple industries, including entertainment companies creating character merchandise, healthcare facilities developing therapeutic comfort items, educational institutions producing mascots and learning aids, retail brands manufacturing promotional products, and individual customers seeking personalized gifts. Corporate clients leverage plush custom design for trade show giveaways, employee recognition programs, and customer loyalty initiatives. The design process involves collaborative consultation sessions where clients work directly with skilled designers to refine concepts, select appropriate materials, and establish production timelines. Quality assurance protocols ensure that each plush custom design meets safety standards, durability requirements, and aesthetic expectations. The manufacturing process accommodates various production volumes, from small batches for limited editions to large-scale runs for commercial distribution. Advanced printing techniques allow for photorealistic reproductions of logos, artwork, and detailed graphics on fabric surfaces. The versatility of plush custom design enables creation of products ranging from simple stuffed animals to complex multi-component toys with interactive features, sound modules, or specialized textures for sensory applications.