Selecting the right custom plush maker is a critical decision that can significantly impact your business success, product quality, and customer satisfaction. Whether you're developing branded merchandise, creating promotional items, or launching a toy line, partnering with an experienced custom plush maker ensures your vision becomes reality with precision and reliability. The manufacturing landscape offers numerous options, but finding a custom plush maker that aligns with your specific requirements demands careful evaluation and strategic consideration.

Understanding Manufacturing Capabilities and Expertise

Production Capacity and Scale

A reliable custom plush maker must demonstrate adequate production capacity to meet your order requirements within specified timeframes. Manufacturing facilities with modern equipment and streamlined processes can handle both small-batch prototyping and large-scale production runs efficiently. When evaluating potential partners, assess their monthly production volumes, peak capacity during busy seasons, and ability to scale operations based on your growing demands.

Consider the custom plush maker's workforce size and training standards, as skilled artisans directly influence product consistency and quality. Facilities with dedicated teams for different production stages, from pattern creation to final assembly, typically deliver superior results compared to smaller operations with limited specialization. Additionally, examine their production scheduling flexibility and ability to accommodate rush orders or seasonal fluctuations in demand.

Technical Design and Prototyping Services

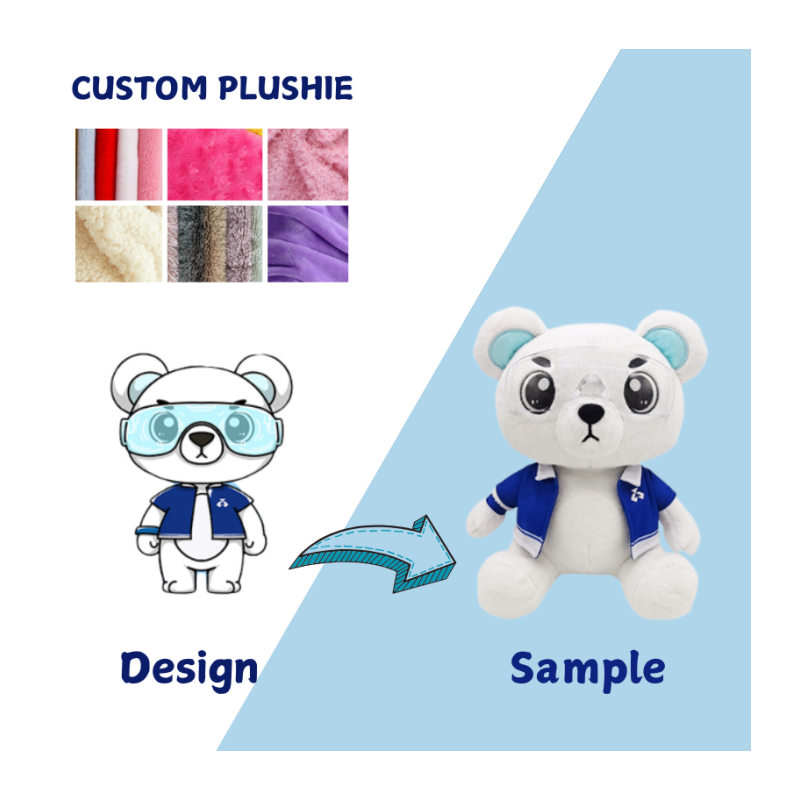

Professional custom plush maker services should include comprehensive design support and rapid prototyping capabilities. Look for manufacturers who employ experienced designers familiar with various plush construction techniques, fabric selection, and safety compliance requirements. These experts can transform your initial concepts into detailed technical drawings and three-dimensional prototypes that accurately represent your final product vision.

The prototyping process reveals crucial information about material behavior, structural integrity, and manufacturing feasibility before committing to full production. A competent custom plush maker will provide multiple prototype iterations, incorporating your feedback and suggestions to refine the design progressively. This collaborative approach minimizes production risks and ensures the final product meets your exact specifications and quality standards.

Quality Standards and Compliance Requirements

International Safety Certifications

Safety compliance represents a non-negotiable aspect when selecting a custom plush maker, particularly for products intended for children or promotional distribution. Reputable manufacturers maintain current certifications including CPSC, EN71, ASTM, and other relevant international toy safety standards. These certifications demonstrate commitment to product safety and provide legal protection for your brand and customers.

Verify that your chosen custom plush maker conducts regular testing for chemical content, choking hazards, flammability, and mechanical safety. Comprehensive testing protocols should cover all components including fabrics, stuffing materials, eyes, accessories, and decorative elements. Request documentation of recent test reports and ensure the manufacturer maintains relationships with accredited third-party testing laboratories.

Material Quality and Sourcing Practices

The quality of raw materials directly affects the durability, appearance, and safety of finished plush products. A professional custom plush maker should source fabrics, filling materials, and accessories from certified suppliers who meet international quality standards. High-grade synthetic fabrics, hypoallergenic stuffing, and lead-free components ensure product longevity and consumer safety.

Sustainable sourcing practices are increasingly important for brand reputation and environmental responsibility. Many custom plush maker facilities now offer eco-friendly material options including recycled polyester filling, organic cotton fabrics, and biodegradable packaging solutions. Discuss your sustainability goals and requirements to identify manufacturers who can support your environmental commitments while maintaining product quality.

Communication and Project Management Excellence

Language Proficiency and Cultural Understanding

Effective communication forms the foundation of successful partnerships with any custom plush maker. Language barriers can lead to misunderstandings, design errors, and production delays that ultimately impact your project timeline and budget. Prioritize manufacturers with English-speaking project managers and sales representatives who understand Western business practices and communication styles.

Cultural awareness extends beyond language proficiency to include understanding of market preferences, regulatory requirements, and business etiquette in your target markets. A custom plush maker with international experience can provide valuable insights about design adaptations, packaging requirements, and distribution considerations for different geographic regions. This expertise proves invaluable when developing products for global markets or specific demographic segments.

Project Timeline Management and Delivery Reliability

Reliable project management separates professional custom plush maker operations from less experienced competitors. Established manufacturers utilize project management software and systems that provide real-time updates on production progress, quality checkpoints, and shipping schedules. Transparent communication about potential delays or challenges allows for proactive problem-solving and alternative planning.

Evaluate the manufacturer's track record for on-time delivery and their contingency plans for addressing production disruptions. A dependable custom plush maker maintains buffer time in production schedules, alternative supplier relationships, and expedited shipping options to meet critical deadlines. Request references from previous clients and inquire about their experiences with delivery reliability and crisis management.

Cost Structure and Value Proposition Analysis

Transparent Pricing Models

Understanding the complete cost structure is essential when comparing different custom plush maker options. Professional manufacturers provide detailed quotations that itemize costs for design services, tooling, materials, labor, quality testing, and shipping. Transparent pricing eliminates hidden fees and allows for accurate budget planning and cost comparison across multiple suppliers.

Consider both unit costs and total project expenses when evaluating pricing proposals. Some custom plush maker facilities offer competitive per-unit pricing but charge additional fees for design revisions, expedited production, or special packaging requirements. Others may have higher base prices but include comprehensive services that reduce overall project costs and management complexity.

Long-term Partnership Benefits

Establishing a long-term relationship with a reliable custom plush maker provides numerous advantages beyond individual project savings. Volume discounts, priority scheduling, reduced tooling costs for repeat orders, and streamlined communication processes all contribute to improved efficiency and cost-effectiveness over time. Many manufacturers offer loyalty programs or preferred customer benefits that reward ongoing partnerships.

Consider the manufacturer's capacity for growth and their willingness to adapt to your evolving needs. A custom plush maker that invests in new technologies, expands production capabilities, and develops innovative materials can support your business growth and product development initiatives. This strategic alignment creates mutual benefits and competitive advantages in dynamic market conditions.

Technology Integration and Innovation Capabilities

Digital Design and Collaboration Tools

Modern custom plush maker operations leverage advanced technology to streamline design processes and enhance collaboration efficiency. Computer-aided design software, 3D modeling capabilities, and virtual prototyping tools enable rapid concept development and visualization before physical prototype creation. These technologies reduce development time and costs while improving design accuracy and client satisfaction.

Cloud-based collaboration platforms allow real-time sharing of design files, production updates, and quality inspection reports. A technologically advanced custom plush maker provides secure access to project portals where clients can review progress, approve design changes, and communicate with production teams directly. This transparency builds confidence and enables proactive project management throughout the manufacturing process.

Innovative Manufacturing Techniques

Leading custom plush maker facilities continuously invest in new manufacturing technologies and techniques to improve product quality and production efficiency. Automated cutting systems ensure precise pattern accuracy and material utilization, while computerized embroidery machines deliver consistent decorative elements and branding applications. Advanced quality control systems using machine vision and automated testing reduce human error and improve consistency.

Innovation extends to material applications and construction methods that enhance product functionality and appeal. Some custom plush maker operations offer specialized techniques including heat-sealed seams for washability, antimicrobial treatments for hygiene applications, and electronic component integration for interactive features. These capabilities open new product possibilities and competitive advantages in crowded markets.

FAQ

What minimum order quantities do custom plush maker companies typically require?

Most professional custom plush maker facilities require minimum orders ranging from 300 to 1,000 pieces per design, depending on complexity and customization level. Smaller quantities may be available for prototype development or testing purposes, but unit costs increase significantly for low-volume production. Some manufacturers offer flexible minimums for repeat customers or simple designs using existing molds and patterns.

How long does the complete production process take from design to delivery?

The typical timeline for custom plush production spans 4-8 weeks, including design finalization, prototype creation, production, and quality inspection. Complex designs with multiple components or special features may require additional time for development and testing. Rush orders are sometimes possible with expedited fees, but proper planning with adequate lead time ensures optimal quality and cost-effectiveness.

What design files and specifications should I provide to a custom plush maker?

Provide high-resolution artwork, detailed dimensions, color specifications using Pantone references, and any special requirements for materials or features. If available, include reference photos from multiple angles and notes about texture preferences or functional requirements. Most custom plush maker teams can work with various file formats but prefer vector graphics for logos and detailed technical drawings for complex shapes.

How can I verify the quality and reliability of a potential custom plush maker partner?

Request samples of similar products, review client testimonials and case studies, and verify current safety certifications and facility inspections. Conduct video tours of production facilities when possible, and communicate directly with project managers to assess their expertise and communication skills. A reputable custom plush maker will readily provide references and documentation to demonstrate their capabilities and track record.

Table of Contents

- Understanding Manufacturing Capabilities and Expertise

- Quality Standards and Compliance Requirements

- Communication and Project Management Excellence

- Cost Structure and Value Proposition Analysis

- Technology Integration and Innovation Capabilities

-

FAQ

- What minimum order quantities do custom plush maker companies typically require?

- How long does the complete production process take from design to delivery?

- What design files and specifications should I provide to a custom plush maker?

- How can I verify the quality and reliability of a potential custom plush maker partner?