Bringing a unique plush toy concept to life requires the expertise of a skilled custom plush manufacturer who understands both creative vision and production capabilities. The journey from initial design sketch to finished product involves multiple specialized stages that transform your imagination into a tangible, huggable reality. Working with an experienced custom plush manufacturer ensures that every detail of your vision is captured while meeting safety standards and quality requirements that make your plush toy suitable for its intended market.

The manufacturing process begins with understanding your specific requirements, target audience, and intended use case. Whether you need promotional items, retail products, or special commemorative pieces, a professional custom plush manufacturer will guide you through design considerations that balance creativity with manufacturability. This collaborative approach ensures that your final product not only looks amazing but also functions properly and can be produced efficiently at your desired volume.

Design Development and Conceptualization

Initial Consultation and Requirements Gathering

The first step in working with a custom plush manufacturer involves detailed discussions about your vision, budget, timeline, and intended market. During this phase, manufacturers assess the complexity of your design, identify potential challenges, and provide recommendations for materials, sizes, and construction methods. This consultation process helps establish realistic expectations and ensures that both parties understand the project scope before moving forward with development.

Professional manufacturers will ask about safety requirements, age groups, packaging needs, and quantity expectations during initial meetings. These factors significantly influence design choices and production methods. A reputable custom plush manufacturer will also discuss intellectual property considerations, ensuring that your original designs remain protected throughout the manufacturing process.

Technical Drawing and Pattern Creation

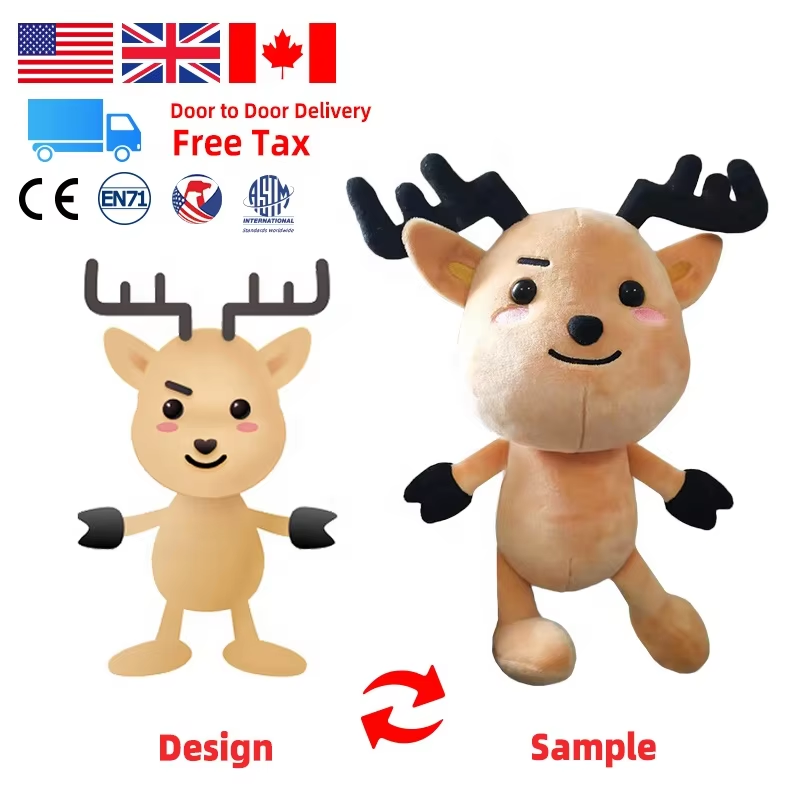

Once the concept is finalized, skilled pattern makers translate your 2D artwork into technical specifications that guide the manufacturing process. This involves creating detailed technical drawings that specify dimensions, seam placements, fabric types, and construction methods. The pattern creation phase is crucial because it determines how the final product will look, feel, and function when assembled.

During pattern development, experienced teams consider factors like fabric stretch, stuffing distribution, and structural integrity. They create templates that ensure consistent reproduction across large production runs while maintaining the design's intended proportions and aesthetic appeal. This technical foundation allows the custom plush manufacturer to produce samples that accurately represent your vision.

Material Selection and Sourcing

Fabric Types and Quality Considerations

Material selection significantly impacts both the appearance and durability of your finished plush toy. A knowledgeable custom plush manufacturer maintains relationships with fabric suppliers who provide high-quality materials that meet international safety standards. Common fabric options include minky, fleece, cotton blends, and specialized textiles that offer unique textures or properties like water resistance or antimicrobial treatment.

The choice of fabric affects not only the tactile experience but also the manufacturing process itself. Different materials require specific handling techniques, cutting methods, and sewing approaches. Experienced manufacturers understand how various fabrics behave during production and can recommend options that balance your aesthetic preferences with practical manufacturing considerations.

Safety Standards and Compliance

Safety compliance represents a critical aspect of material selection that cannot be overlooked. Professional manufacturers ensure that all materials, including fabrics, stuffing, threads, and hardware components, meet relevant safety standards such as CPSIA, EN71, or other regional requirements. This includes testing for chemical content, flammability, and mechanical safety features that prevent choking hazards or other injuries.

A responsible custom plush manufacturer maintains documentation for all materials used in production and can provide certificates of compliance when required. They stay updated on changing regulations and proactively ensure that their manufacturing processes meet current safety requirements for different markets worldwide.

Prototype Development and Testing

Sample Creation Process

Creating prototypes allows you to evaluate your design concept before committing to full production. The sample creation process typically involves hand-cutting fabric pieces according to the approved patterns and assembling them using the same techniques planned for mass production. This initial prototype reveals how the design translates from concept to physical reality and identifies any necessary adjustments.

During prototype development, manufacturers pay close attention to proportions, seam placement, stuffing distribution, and overall construction quality. They may create multiple iterations to refine the design, making adjustments based on your feedback and their technical expertise. This iterative approach ensures that the final prototype accurately represents your vision while meeting manufacturing requirements.

Quality Assessment and Refinement

Once prototypes are complete, thorough quality assessment helps identify areas for improvement before proceeding to production. This evaluation covers aesthetic elements like color matching, proportional accuracy, and overall appearance, as well as functional aspects such as durability, safety features, and user experience. Manufacturers conduct stress tests to ensure seams hold properly and stuffing remains evenly distributed during normal use.

The refinement process may involve multiple prototype iterations as adjustments are made to improve quality, reduce manufacturing complexity, or address specific feedback points. An experienced custom plush manufacturer uses this phase to optimize the design for both quality and cost-effectiveness while maintaining the creative integrity of your original concept.

Production Planning and Manufacturing

Production Scaling and Workflow Management

Transitioning from approved prototypes to full production requires careful planning to ensure consistency and quality across large quantities. Manufacturers develop detailed production schedules that coordinate fabric cutting, sewing operations, stuffing, finishing work, and quality control checkpoints. This systematic approach ensures that each finished piece meets the same standards as the approved prototype.

Efficient workflow management allows custom plush manufacturer facilities to handle complex orders while maintaining quality standards. They organize production lines to minimize handling time, reduce waste, and ensure consistent results throughout the manufacturing process. Experienced teams understand how to balance speed with quality to meet delivery deadlines without compromising product standards.

Quality Control and Final Inspection

Comprehensive quality control measures are implemented throughout the manufacturing process to catch and correct issues before they affect finished products. This includes inspections at various stages, from fabric preparation through final packaging. Quality control teams check for proper construction, accurate proportions, color consistency, and adherence to safety standards.

Final inspection processes typically include detailed visual examinations, functionality testing, and compliance verification. Products that do not meet established standards are identified and corrected before packaging. This systematic approach to quality control ensures that customers receive products that meet their expectations and maintain the reputation of both the brand and the custom plush manufacturer.

Packaging and Delivery Considerations

Custom Packaging Solutions

Packaging plays a crucial role in product presentation and protection during shipping and retail display. Many manufacturers offer custom packaging solutions that complement your plush toy design while providing adequate protection during transport. Options range from simple poly bags to elaborate display boxes that enhance the unboxing experience and support marketing objectives.

Professional packaging design considers factors like product size, shipping requirements, retail display needs, and environmental considerations. A knowledgeable custom plush manufacturer can recommend packaging solutions that balance protection, presentation, and cost-effectiveness while supporting your brand image and marketing goals.

Shipping and Logistics Coordination

Efficient shipping and logistics coordination ensures that your finished products arrive on schedule and in perfect condition. Experienced manufacturers work with reliable shipping partners who understand the special handling requirements for plush toys and other soft goods. They coordinate pickup schedules, documentation requirements, and tracking systems that keep you informed throughout the delivery process.

International shipping requires additional considerations including customs documentation, import regulations, and compliance certificates. Professional manufacturers handle these requirements smoothly, ensuring that your products clear customs efficiently and reach their destination without delays or complications that could impact your launch timeline or customer satisfaction.

Working Relationship and Communication

Project Management and Updates

Effective communication throughout the manufacturing process keeps projects on track and ensures that expectations are met at every stage. Professional manufacturers assign dedicated project managers who serve as your primary contact point and coordinate between design teams, production staff, and quality control departments. Regular updates keep you informed about progress, potential challenges, and milestone achievements.

Modern custom plush manufacturer facilities often provide online portals or digital communication systems that allow real-time project tracking and easy access to important documents, photos, and production updates. This transparency builds trust and allows for quick decision-making when adjustments or approvals are needed during the manufacturing process.

Long-term Partnership Benefits

Building a strong relationship with a reliable custom plush manufacturer provides advantages that extend beyond individual projects. Established partnerships lead to better pricing, priority scheduling, and streamlined processes for future orders. Manufacturers who understand your brand values, quality expectations, and design preferences can work more efficiently and suggest improvements based on their accumulated knowledge of your requirements.

Long-term relationships also facilitate innovation and product development opportunities. Experienced partners stay informed about new materials, manufacturing techniques, and market trends that could benefit your products. They may suggest design improvements, cost optimizations, or new product possibilities that align with your brand strategy and market positioning.

FAQ

How long does the custom plush manufacturing process typically take?

The timeline for custom plush manufacturing varies depending on design complexity, order quantity, and production schedule. Simple designs with standard materials may be completed in 4-6 weeks from approval to delivery, while complex projects with custom fabrics or special features may require 8-12 weeks. Prototype development typically adds 1-2 weeks to the overall timeline. Manufacturers provide specific timelines based on your project requirements during the initial consultation phase.

What is the minimum order quantity for custom plush toys?

Minimum order quantities vary among custom plush manufacturer facilities, typically ranging from 100 to 1,000 pieces depending on design complexity and production requirements. Some manufacturers offer lower minimums for simple designs or repeat orders, while complex projects with multiple components may require higher quantities to justify setup costs. Many facilities provide quantity breaks that reduce per-unit costs for larger orders, making higher quantities more economical for businesses.

Can manufacturers help with design modifications to reduce production costs?

Experienced manufacturers often suggest design modifications that can reduce production costs without compromising the overall concept. These may include simplifying construction techniques, reducing the number of fabric colors, optimizing sizes for efficient cutting, or suggesting alternative materials that provide similar aesthetic results at lower costs. Professional teams understand how design choices impact manufacturing complexity and can recommend changes that balance quality, appearance, and budget considerations.

What intellectual property protections are available during manufacturing?

Reputable custom plush manufacturer facilities typically offer non-disclosure agreements and confidentiality protections for proprietary designs. Many maintain secure facilities with restricted access to design files and finished samples. Some manufacturers also provide design registration services or work with intellectual property attorneys to help protect original concepts. It is important to discuss IP protection requirements during initial negotiations and ensure that appropriate agreements are in place before sharing detailed design information.