Finding the right custom plush manufacturer in 2025 requires careful evaluation and strategic questioning. The plush toy industry has evolved significantly, with new technologies, sustainability requirements, and quality standards reshaping manufacturing processes. Whether you're launching a new brand, creating promotional merchandise, or developing educational toys, partnering with the right custom plush manufacturer can determine your product's success in the competitive marketplace. Understanding what questions to ask ensures you select a manufacturer that aligns with your vision, budget, and timeline while meeting modern industry standards.

Manufacturing Capabilities and Technical Expertise

Production Capacity and Scalability

When evaluating a custom plush manufacturer, understanding their production capacity is fundamental to your business planning. Ask about their monthly output capabilities, peak season handling, and ability to scale production based on demand fluctuations. A reliable custom plush manufacturer should provide clear information about their facility size, number of production lines, and workforce capacity. This information helps you determine whether they can accommodate your initial orders and potential growth.

Inquire about their flexibility in handling both small batch orders and large-scale production runs. Many businesses start with smaller quantities to test market response before scaling up. A competent custom plush manufacturer should demonstrate experience with various order sizes and provide transparent pricing structures that reflect economies of scale. Understanding their minimum order quantities and lead times for different production volumes will help you plan your inventory and launch strategies effectively.

Design and Customization Services

The design capabilities of your chosen custom plush manufacturer directly impact your product's uniqueness and market appeal. Ask about their in-house design team, CAD capabilities, and prototype development process. A professional custom plush manufacturer should offer comprehensive design services, from initial concept sketches to detailed technical drawings and 3D modeling. They should also provide guidance on design feasibility, cost optimization, and manufacturing considerations that might affect your vision.

Discuss their experience with different plush styles, sizes, and complexity levels. Some manufacturers excel at simple designs while others specialize in intricate, multi-component toys with electronic features or mechanical elements. Understanding their design limitations and strengths helps you align your product requirements with their capabilities. Additionally, inquire about their intellectual property protection measures and confidentiality agreements to safeguard your unique designs throughout the development process.

Quality Control and Compliance Standards

Safety Certifications and Testing Protocols

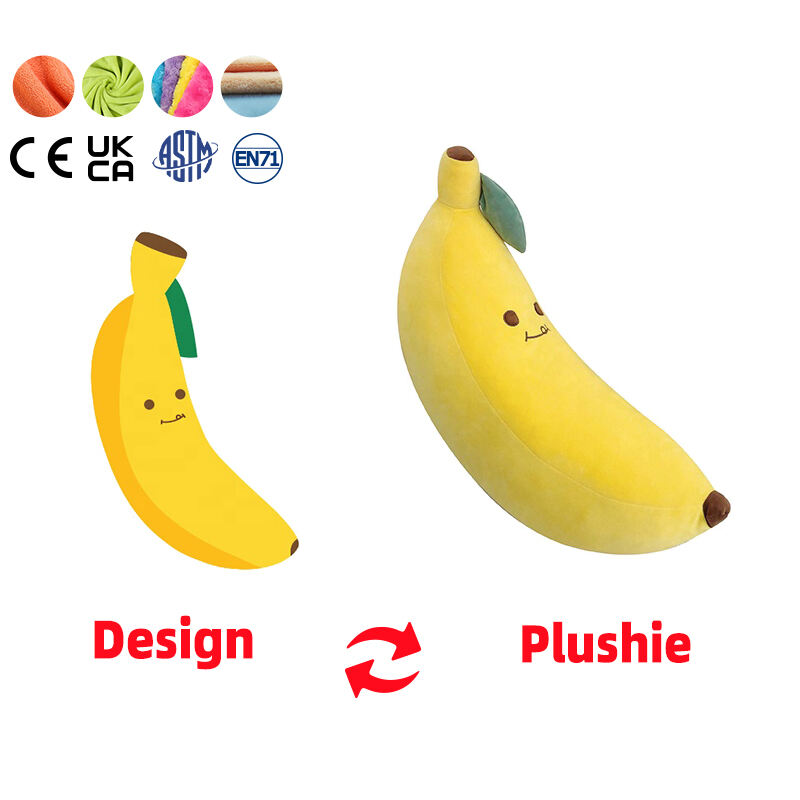

Product safety is paramount in the plush toy industry, especially when targeting children's markets. Ask your prospective custom plush manufacturer about their safety certifications, including CE marking, CPSIA compliance, and other relevant regional standards. A reputable manufacturer should maintain current certifications and provide documentation proving their adherence to safety regulations. They should also demonstrate knowledge of age-appropriate design guidelines and restricted materials lists.

Inquire about their testing protocols and quality assurance procedures throughout the production process. A professional custom plush manufacturer should conduct regular testing for mechanical hazards, chemical composition, flammability, and choking hazards. They should provide detailed test reports and maintain traceability records for all materials and components used in production. Understanding their recall procedures and liability insurance coverage also provides additional peace of mind for your business operations.

Material Selection and Sourcing

The materials used in plush toy manufacturing significantly impact product quality, safety, and cost. Ask about their material sourcing policies, supplier relationships, and quality control measures for incoming materials. A reliable custom plush manufacturer should work with certified suppliers and maintain strict material inspection procedures. They should also offer various fabric options, filling materials, and component choices to meet different quality levels and price points.

Discuss their approach to sustainable and eco-friendly materials, as environmental consciousness increasingly influences consumer purchasing decisions. Many custom plush manufacturer operations now offer recycled polyester stuffing, organic cotton fabrics, and biodegradable packaging options. Understanding their sustainability initiatives and certifications can help differentiate your products in environmentally conscious markets while supporting corporate social responsibility goals.

Communication and Project Management

Language Capabilities and Time Zone Considerations

Effective communication is crucial when working with a custom plush manufacturer, particularly for international partnerships. Assess their English proficiency levels, communication protocols, and availability during your business hours. A professional manufacturer should have dedicated account managers or project coordinators who can communicate clearly and respond promptly to inquiries. They should also provide regular project updates and maintain transparent communication throughout the production process.

Consider the time zone differences and their impact on project timelines and problem resolution. Some custom plush manufacturer teams offer extended support hours or maintain staff in different time zones to accommodate international clients. Understanding their communication preferences, whether through email, video calls, or project management platforms, helps establish efficient working relationships and prevents misunderstandings that could delay production.

Project Timeline and Milestone Management

Establishing clear timelines and milestones is essential for successful collaboration with any custom plush manufacturer. Ask about their typical project phases, from initial design to final delivery, and the expected duration for each stage. A experienced manufacturer should provide detailed project schedules that account for design revisions, prototype development, tooling creation, production time, and quality inspection periods.

Inquire about their contingency planning for potential delays and their track record for meeting delivery commitments. Understanding their peak production periods, holiday schedules, and capacity constraints helps you plan your product launches and inventory management more effectively. A reliable custom plush manufacturer should also offer expedited production options for urgent orders, though these typically come with additional costs that should be clearly communicated upfront.

Pricing Structure and Payment Terms

Cost Transparency and Hidden Fees

Understanding the complete cost structure is vital when selecting a custom plush manufacturer for your project. Request detailed quotations that break down all charges, including design fees, tooling costs, material expenses, production charges, and any additional services. A transparent manufacturer should clearly explain their pricing methodology and provide written estimates that remain valid for a specified period. This clarity helps you budget accurately and compare different manufacturers objectively.

Ask about potential additional costs that might arise during production, such as design modification fees, rush order charges, or packaging upgrades. Some custom plush manufacturer operations charge separately for services like prototype development, color matching, or special packaging requirements. Understanding these potential costs upfront prevents budget surprises and helps you make informed decisions about optional services that might enhance your product but increase overall expenses.

Payment Terms and Financial Arrangements

Payment terms significantly impact your cash flow and financial planning, making this an important discussion point with any custom plush manufacturer. Inquire about their standard payment schedules, deposit requirements, and accepted payment methods. Many manufacturers require deposits ranging from 30% to 50% of the total order value, with the balance due before shipment or upon delivery. Understanding these requirements helps you plan your working capital needs accordingly.

Discuss their policies regarding payment protection, order cancellations, and partial shipments. Some custom plush manufacturer companies offer flexible payment terms for established clients or large orders, while others maintain strict policies regardless of order size. Understanding their approach to payment disputes and refund procedures provides additional security for your investment and helps establish mutual trust in the business relationship.

Logistics and Shipping Capabilities

International Shipping and Customs Handling

For businesses importing products from overseas custom plush manufacturer facilities, understanding shipping and logistics capabilities is crucial. Ask about their experience with international shipping, preferred freight forwarders, and customs documentation procedures. A experienced manufacturer should provide guidance on shipping methods, transit times, and cost optimization strategies for different delivery requirements and destinations.

Inquire about their packaging standards and protection measures for long-distance shipping. Plush toys require careful packaging to maintain their appearance and prevent damage during transit. A professional custom plush manufacturer should use appropriate packaging materials and methods to ensure products arrive in perfect condition. They should also provide tracking information and insurance options to protect your investment during shipping.

Inventory Management and Drop Shipping Services

Some custom plush manufacturer operations offer additional services like inventory management and drop shipping, which can streamline your business operations. Ask about their warehousing capabilities, inventory tracking systems, and ability to ship directly to your customers or retail partners. These services can reduce your overhead costs and improve order fulfillment efficiency, particularly for e-commerce businesses or those with multiple distribution channels.

Discuss their minimum inventory requirements, storage fees, and order processing times for warehoused products. Understanding their inventory management capabilities helps you evaluate whether these services align with your business model and provide sufficient value to justify any additional costs. Some manufacturers also offer kitting services, combining multiple products into custom packages or promotional sets.

FAQ

How long does it typically take to develop and produce custom plush toys

The timeline for custom plush toy development and production varies depending on design complexity, order quantity, and manufacturer capacity. Generally, the complete process from initial concept to finished products takes 4-8 weeks. This includes 1-2 weeks for design development and prototype creation, 1-2 weeks for sample approval and revisions, and 2-4 weeks for bulk production. A experienced custom plush manufacturer should provide detailed timeline estimates based on your specific requirements and their current production schedule.

What minimum order quantities should I expect from manufacturers

Minimum order quantities vary significantly among custom plush manufacturer facilities, typically ranging from 100 to 1,000 pieces per design. Factors affecting MOQs include product complexity, size, number of colors, and special features. Some manufacturers offer lower MOQs for simple designs or first-time clients, while complex toys with electronic components or multiple fabric types may require higher minimum orders. It's important to discuss MOQ flexibility and potential for staged production to accommodate your budget and market testing needs.

How can I ensure the quality and safety of my custom plush products

Ensuring quality and safety requires selecting a custom plush manufacturer with proper certifications and testing capabilities. Look for manufacturers with current CE, CPSIA, or other relevant safety certifications. Request to see their testing reports, quality control procedures, and facility inspection records. Additionally, consider conducting third-party testing through independent laboratories to verify compliance with safety standards. A reputable manufacturer should welcome quality discussions and provide transparency about their testing protocols and safety measures.

What intellectual property protections should I expect from manufacturers

Intellectual property protection is crucial when working with any custom plush manufacturer, especially for unique or proprietary designs. Reputable manufacturers should offer comprehensive non-disclosure agreements (NDAs) and intellectual property protection clauses in their contracts. They should also maintain confidentiality throughout the design and production process and implement security measures to prevent unauthorized reproduction of your designs. Discuss their policies regarding design ownership, sample retention, and measures they take to prevent intellectual property theft or unauthorized distribution.