Planning your custom plush project requires careful timing considerations to ensure optimal results. Understanding when to engage with a custom plush maker can make the difference between a successful product launch and missed opportunities. The timing of your order affects everything from production quality to cost efficiency, making it crucial to align your needs with industry manufacturing cycles.

The global plush manufacturing industry operates on seasonal patterns that significantly impact production schedules and pricing. Most manufacturers experience peak demand periods during specific months, affecting their capacity to handle new orders. By understanding these cycles, businesses can strategically time their orders to secure better pricing, faster turnaround times, and higher priority in production queues.

Understanding Seasonal Manufacturing Cycles

Peak Production Periods

Custom plush maker facilities typically experience their highest demand from June through September as retailers prepare for holiday seasons. During this period, manufacturers allocate significant capacity to established clients and large-volume orders. Companies planning custom plush products should expect longer lead times and potentially higher costs when ordering during these peak months.

The manufacturing intensity during summer months stems from the retail calendar where holiday merchandise must be completed well before seasonal sales periods. This creates a bottleneck effect where custom plush maker resources become stretched thin. Smart businesses recognize this pattern and adjust their ordering schedules accordingly to avoid the rush.

Off-Peak Advantages

The months of January through April represent the optimal window for engaging with a custom plush maker. During this period, manufacturers have reduced order volumes and increased capacity for new projects. This timing allows for more personalized attention to design details, faster prototype development, and often more competitive pricing structures.

Off-peak ordering also provides opportunities for closer collaboration with design teams. When a custom plush maker has more available time, they can dedicate additional resources to perfecting your product specifications. This enhanced attention to detail often results in superior final products that better meet client expectations and market requirements.

Strategic Timing for Different Business Needs

Product Launch Considerations

Companies planning product launches should work backward from their target release dates when selecting a custom plush maker. Successful launches require adequate time for production, quality testing, marketing material development, and distribution setup. Industry best practices suggest allowing six to eight months from initial order to market release for complex custom plush projects.

The timing becomes even more critical for businesses targeting specific seasonal markets. Holiday-themed products, back-to-school promotions, or seasonal character tie-ins require precise coordination with manufacturing schedules. A professional custom plush maker will help clients understand these timelines and plan accordingly.

Budget Optimization Timing

Financial planning plays a crucial role in determining optimal ordering times. Many custom plush maker companies offer preferential pricing during their slower periods to maintain steady production flow. January through March typically offers the best opportunities for cost-effective manufacturing without compromising quality standards.

Budget-conscious businesses should also consider the payment schedule implications of their timing choices. Early orders often allow for more flexible payment terms and may qualify for volume discounts on future orders. This financial advantage can significantly impact overall project profitability and cash flow management.

Quality and Capacity Considerations

Manufacturing Quality During Different Periods

The quality output from any custom plush maker can vary based on production pressure and resource allocation. During peak periods, manufacturers may experience higher turnover rates among skilled workers and increased pressure to meet deadlines. This environment can potentially impact the attention to detail that custom projects require.

Conversely, off-peak periods allow manufacturing teams to work with less pressure and more focus on quality control processes. Experienced custom plush maker facilities use these periods to train new staff, upgrade equipment, and refine production processes. Clients ordering during these times often benefit from these improvements in operational efficiency.

Resource Allocation and Priority

Understanding how a custom plush maker allocates resources throughout the year helps clients set realistic expectations. During busy periods, new clients may find themselves competing for attention with established accounts who have priority status. This dynamic can affect everything from design consultation time to production scheduling flexibility.

Smart timing allows new clients to establish relationships with manufacturers when they have more capacity for relationship building. These connections formed during slower periods often translate into better service and priority treatment during future busy seasons. The investment in timing can yield long-term partnership benefits beyond the immediate project.

Industry-Specific Timing Strategies

Retail and Consumer Products

Retail businesses working with a custom plush maker must align their ordering with consumer buying patterns and retail calendars. The toy industry follows predictable seasonal trends with major sales periods during holidays, back-to-school seasons, and summer vacation periods. Successful retailers plan their custom plush orders to ensure inventory availability during these peak selling times.

E-commerce businesses have additional flexibility in timing since they can adjust inventory levels more dynamically than traditional retail stores. However, they still benefit from strategic timing to optimize advertising campaigns, seasonal promotions, and customer demand cycles. Working with an experienced custom plush maker helps identify these optimal windows for different market segments.

Corporate and Promotional Uses

Companies using custom plush products for promotional purposes or corporate gifts have different timing considerations. Trade shows, conference schedules, and corporate calendar events drive the urgency for these projects. A reliable custom plush maker will work with corporate clients to establish production schedules that align with business event calendars.

Corporate orders often benefit from early planning since they typically involve approval processes, brand compliance reviews, and coordination with marketing teams. Starting the conversation with a custom plush maker well in advance of needed delivery dates ensures adequate time for these internal processes while securing optimal production scheduling.

Planning and Preparation Timeline

Initial Consultation and Design Phase

The relationship with a custom plush maker begins long before production starts. Initial consultations should occur at least four to six months before desired delivery dates for complex projects. This timeline allows for proper design development, material selection, and prototype creation without rushing critical decisions that affect final product quality.

Design phase timing also affects cost control since rushed design processes may limit material options or require expedited prototyping services. Working with a custom plush maker during their less busy periods often provides access to more design resources and creative consultation time, resulting in better final products.

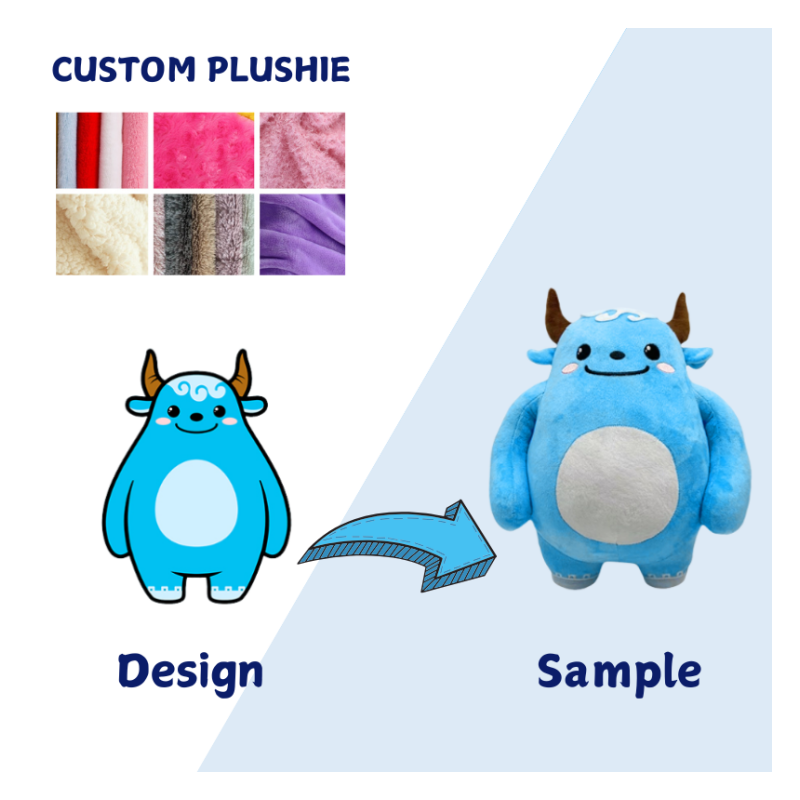

Sample Development and Approval

Sample development represents a critical phase in custom plush manufacturing that requires adequate time allocation. Most projects require multiple sample iterations before final approval, with each round taking several weeks to complete. Understanding this timeline helps clients work with their custom plush maker to establish realistic project schedules.

The sample approval process also involves stakeholder reviews, which can add additional time requirements. Companies should factor in internal approval processes, potential design modifications, and final sign-off procedures when establishing timelines with their chosen custom plush maker. This comprehensive planning prevents delays and ensures smooth production transitions.

FAQ

How far in advance should I contact a custom plush maker for my project

The ideal timeline for contacting a custom plush maker depends on project complexity and desired delivery dates. For standard custom products, initiate contact at least three to four months before your needed delivery date. Complex projects requiring extensive design work, special materials, or large quantities should begin six to eight months in advance. This timeline ensures adequate time for design development, sampling, revisions, and production without rushing any critical steps.

What months offer the best pricing from custom plush maker companies

January through April typically offer the most competitive pricing from custom plush maker facilities. During these months, manufacturers experience lower order volumes and often provide incentives to maintain steady production flow. Additionally, many companies offer early-bird discounts for orders placed during their slower periods. However, pricing advantages must be balanced against your specific delivery timeline requirements and market launch goals.

Can I expect faster delivery if I order during off-peak periods

Yes, ordering during off-peak periods generally results in faster turnaround times from most custom plush maker companies. With reduced production volumes during January through April, manufacturers can allocate more resources to individual projects and often complete orders ahead of standard timelines. However, delivery speed should not be the only consideration, as rushing any phase of custom manufacturing can potentially compromise quality outcomes.

How do holiday seasons affect custom plush maker production schedules

Holiday seasons significantly impact custom plush maker production schedules, with peak demand occurring from June through September as manufacturers prepare holiday inventory. During these periods, expect longer lead times, higher costs, and less flexibility in production scheduling. Many facilities prioritize existing clients and large-volume orders during peak seasons, potentially pushing smaller or new client orders to later time slots. Planning around these seasonal patterns helps ensure better service and more predictable delivery schedules.