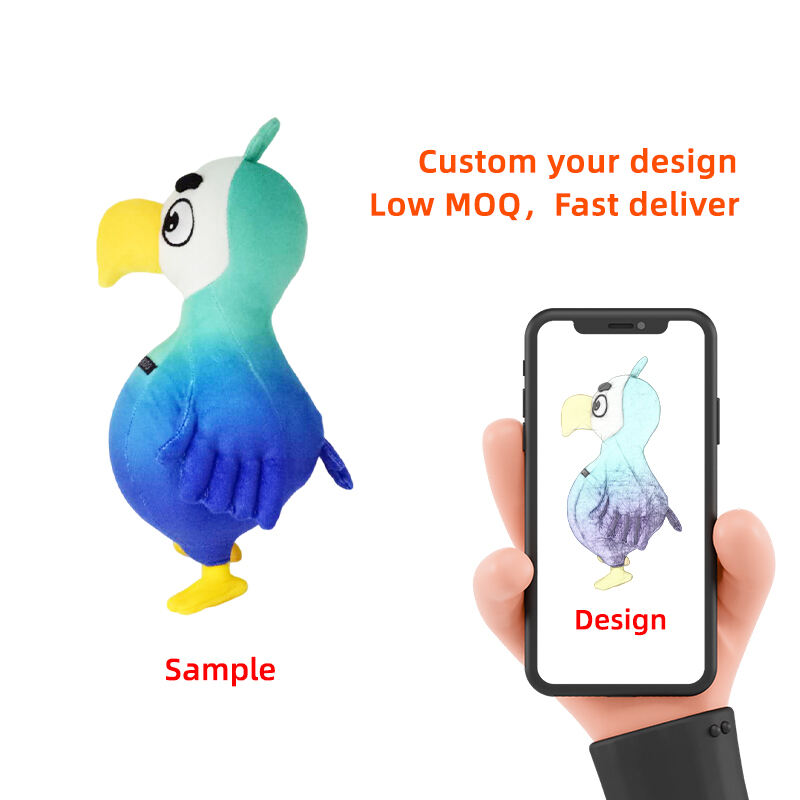

custom soft toy manufacturers

Custom soft toy manufacturers represent a specialized sector of the global toy industry, focusing on creating personalized plush products tailored to specific client requirements. These manufacturers combine traditional craftsmanship with modern production techniques to deliver unique soft toys that meet diverse market demands. The primary function of custom soft toy manufacturers involves transforming creative concepts into tangible plush products through comprehensive design-to-production services. They work closely with brands, retailers, promotional companies, and individual customers to bring imaginative characters and designs to life. The manufacturing process encompasses initial concept development, pattern creation, material selection, prototype development, quality testing, and full-scale production. Custom soft toy manufacturers utilize advanced technologies including computer-aided design software, precision cutting equipment, automated stitching machines, and specialized filling systems. These technological features enable manufacturers to maintain consistency across large production runs while accommodating intricate design specifications. Quality control systems incorporate multi-stage inspection protocols, ensuring each product meets safety standards and client expectations. The applications for custom soft toy manufacturers span numerous industries and purposes. Corporate clients frequently engage these manufacturers for promotional merchandise, brand mascots, and marketing campaigns. Educational institutions utilize custom plush toys for teaching aids and school spirit merchandise. Entertainment companies collaborate with manufacturers to produce licensed character toys and collectibles. Healthcare facilities often commission therapeutic soft toys designed for patient comfort and pediatric care. Retail businesses leverage custom soft toy manufacturers to create exclusive product lines and seasonal collections. Additionally, these manufacturers serve individual customers seeking personalized gifts, memorial keepsakes, or unique celebration items. The versatility of custom soft toy manufacturers allows them to accommodate various production volumes, from small batch specialty items to large-scale commercial orders, making them valuable partners across multiple sectors.