drawing into plush

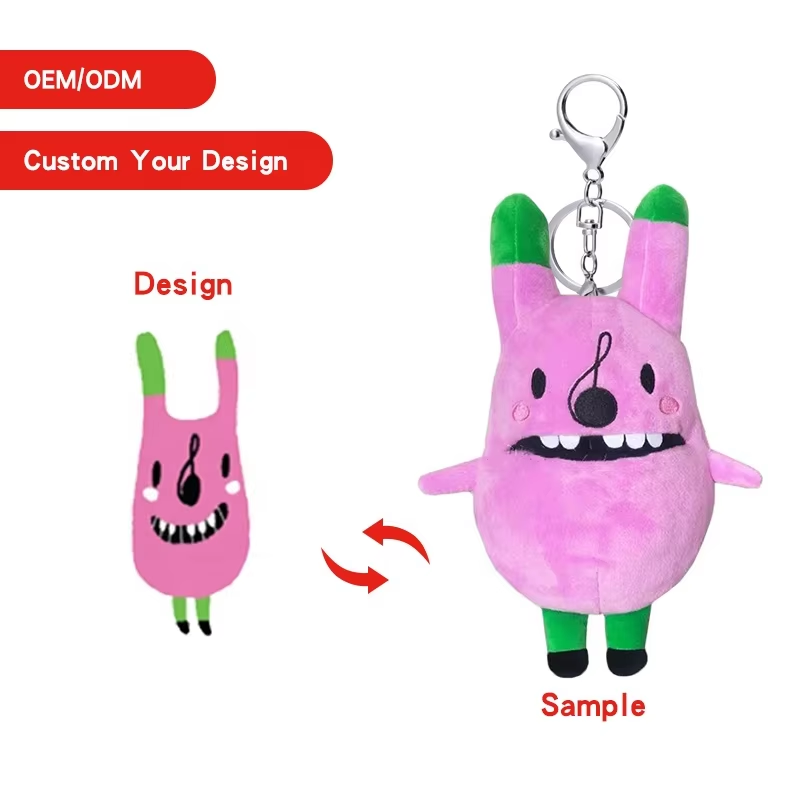

Drawing into plush represents a revolutionary personalized manufacturing service that transforms hand-drawn artwork, digital illustrations, photographs, and creative designs into high-quality custom stuffed animals and plush toys. This innovative process bridges the gap between imagination and reality by converting two-dimensional artwork into three-dimensional soft collectibles that capture the essence and character of original designs. The drawing into plush service utilizes advanced textile manufacturing techniques combined with skilled craftsmanship to create unique, personalized plush toys that serve as memorable keepsakes, promotional items, gifts, or collectible merchandise. The technological foundation of drawing into plush relies on sophisticated pattern-making software that analyzes submitted artwork to determine optimal fabric placement, color matching, and structural design elements. Professional designers work closely with clients to ensure accurate representation of original concepts while maintaining the structural integrity necessary for durable plush construction. The service accommodates various art styles, from simple cartoon characters to complex detailed illustrations, making it accessible to artists, businesses, families, and creative individuals seeking custom plush solutions. Manufacturing processes incorporate premium materials including hypoallergenic fabrics, non-toxic stuffing materials, and durable stitching techniques that ensure long-lasting quality. Quality control measures guarantee that each drawing into plush creation meets safety standards while preserving artistic authenticity. The service typically includes design consultation, pattern development, prototype creation, client approval processes, and final production phases. Drawing into plush applications span multiple industries including entertainment merchandising, corporate branding, educational tools, therapeutic aids, memorial keepsakes, and personalized gift markets. The versatility of drawing into plush makes it suitable for creating mascots, character merchandise, promotional items, children's toys, collector's editions, and unique artistic expressions that cannot be found through traditional retail channels.