soft toy companies

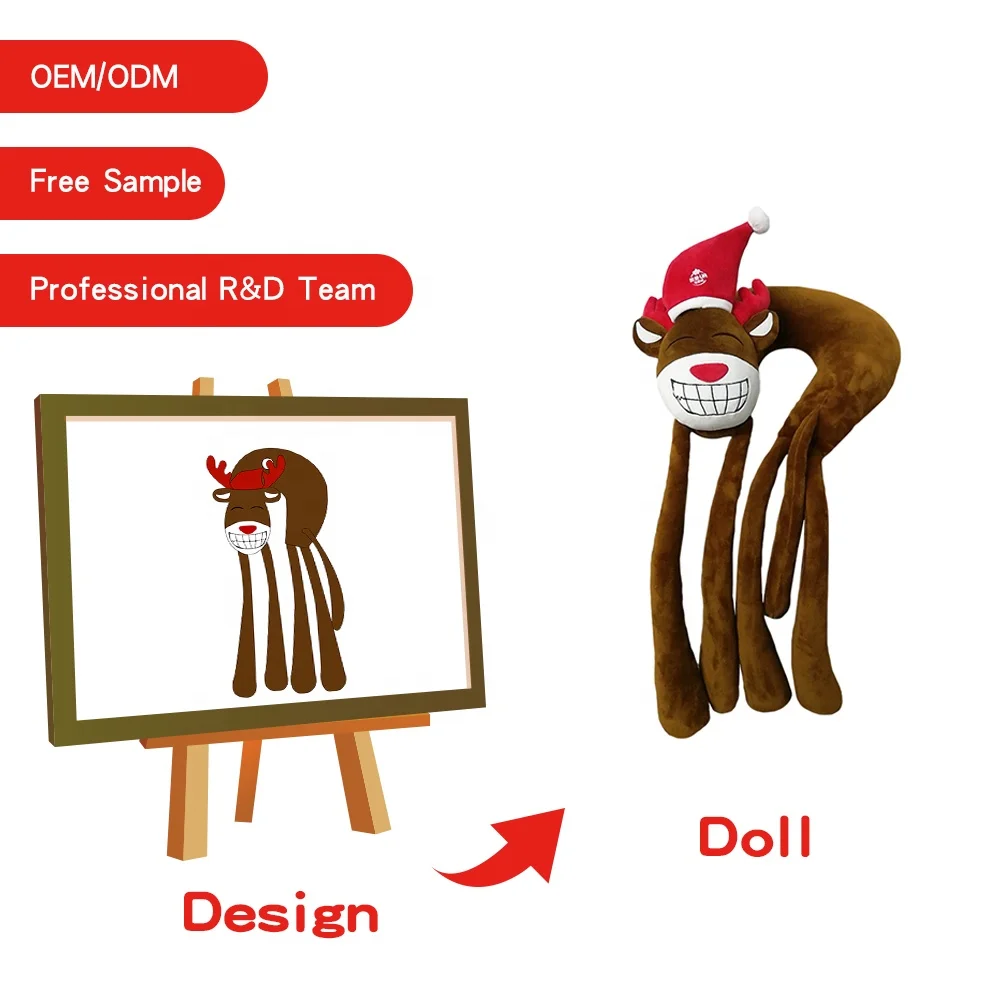

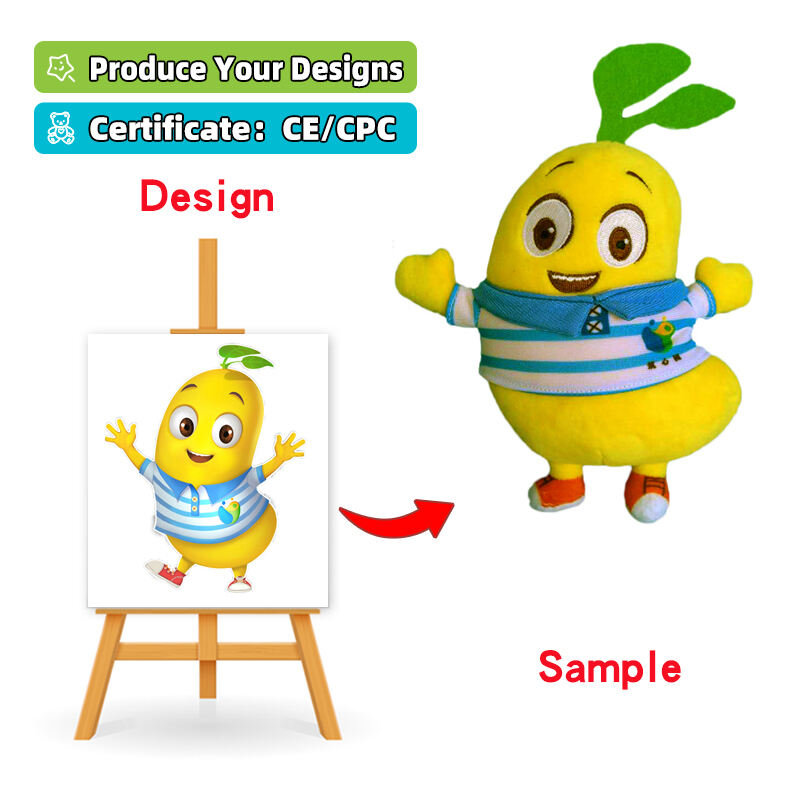

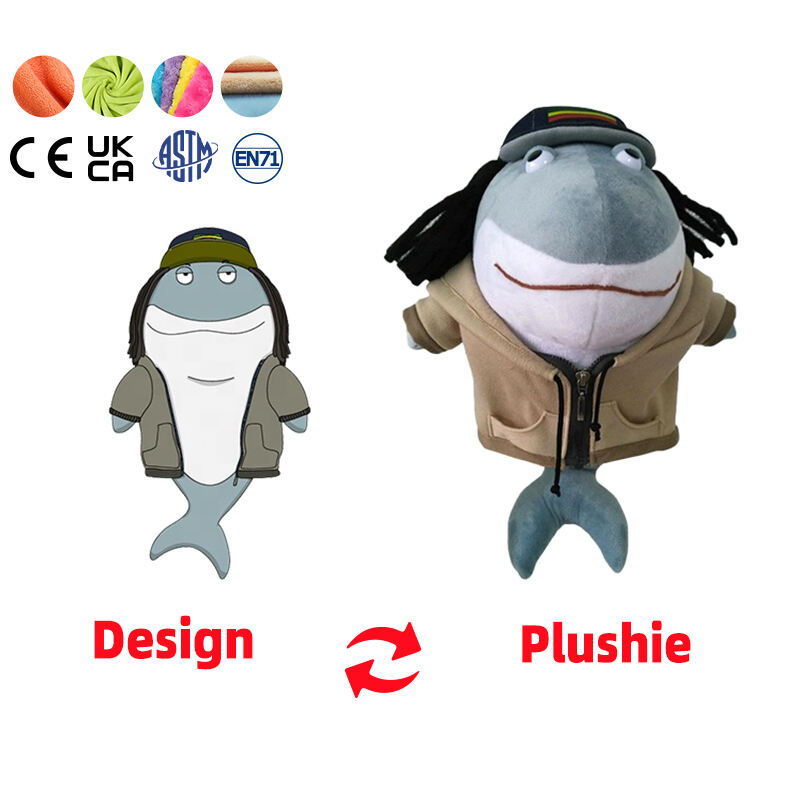

Soft toy companies represent a dynamic sector of the global toy industry, specializing in the design, manufacturing, and distribution of plush toys, stuffed animals, and fabric-based playthings. These enterprises operate across multiple scales, from boutique artisan workshops to multinational corporations, serving diverse markets that span children's entertainment, collectibles, promotional merchandise, and therapeutic applications. The primary functions of soft toy companies encompass product conceptualization, where creative teams develop original characters and designs that resonate with target demographics. Manufacturing capabilities form another core function, utilizing advanced textile technologies, automated stitching systems, and quality control protocols to ensure consistent production standards. Distribution networks enable these companies to reach global markets through retail partnerships, e-commerce platforms, and direct-to-consumer channels. Technological features within modern soft toy companies include computer-aided design software for pattern creation, automated cutting systems for fabric preparation, and sophisticated embroidery machines for detailed finishing. Quality assurance technologies incorporate safety testing equipment to ensure compliance with international toy safety standards, while inventory management systems optimize supply chain efficiency. Many leading soft toy companies now integrate sustainable manufacturing practices, employing eco-friendly materials like organic cotton, recycled polyester filling, and non-toxic dyes. Digital integration has become increasingly important, with companies utilizing social media marketing, influencer partnerships, and augmented reality applications to enhance customer engagement. The applications of soft toy companies extend beyond traditional children's toys to include therapeutic products for hospitals and care facilities, corporate promotional items for brand marketing, educational tools that support learning development, and collectible items that appeal to adult enthusiasts. These companies also serve the entertainment industry by producing licensed merchandise for popular franchises, movies, and television shows, creating additional revenue streams while building brand recognition across diverse consumer segments.