stuffed toy supplier

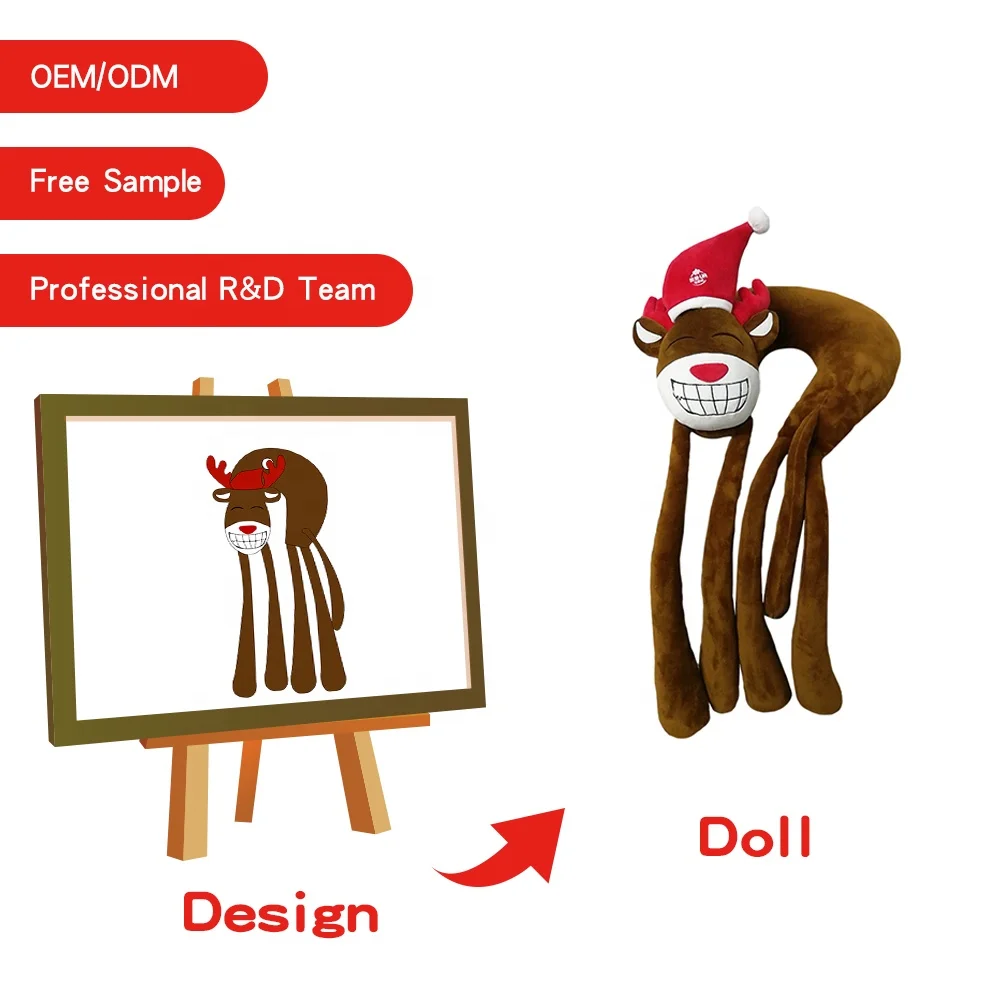

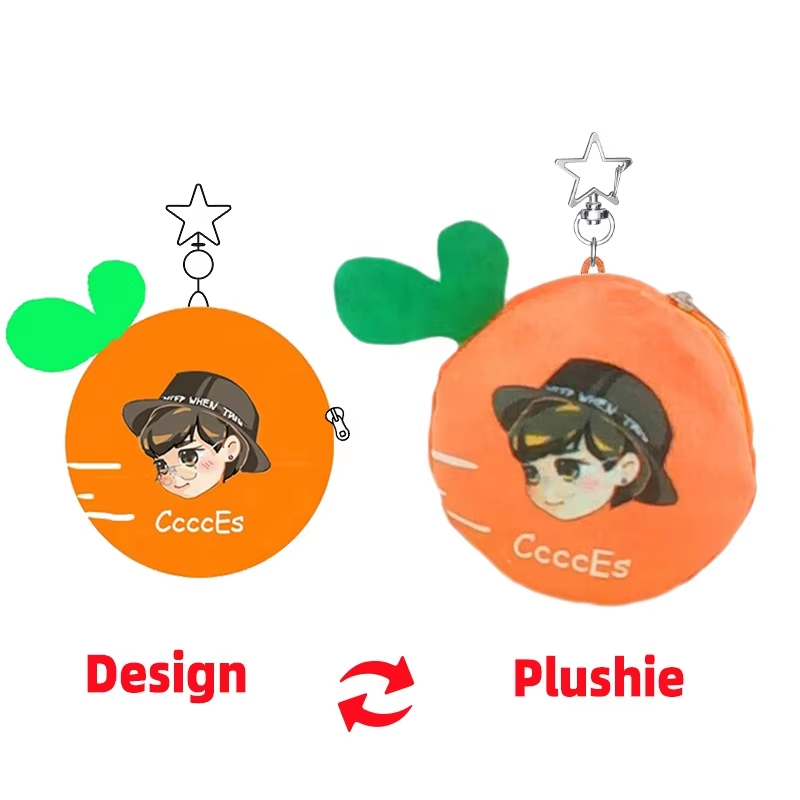

A professional stuffed toy supplier serves as the cornerstone of the global plush toy industry, connecting manufacturers with retailers, distributors, and end consumers through comprehensive sourcing and distribution networks. These specialized suppliers operate as intermediaries who understand market demands, quality standards, and regulatory requirements across different regions. The primary function of a stuffed toy supplier involves sourcing high-quality plush products from certified manufacturers, maintaining inventory management systems, and ensuring timely delivery to customers worldwide. Modern stuffed toy suppliers leverage advanced technological platforms including inventory management systems, customer relationship management tools, and e-commerce integration capabilities to streamline operations. These technological features enable real-time tracking of product availability, automated ordering processes, and seamless communication between suppliers and buyers. Quality assurance represents another critical function, where suppliers implement rigorous testing protocols to ensure products meet international safety standards such as CPSIA, CE marking, and ASTM requirements. The application scope of stuffed toy suppliers extends across multiple sectors including retail toy stores, educational institutions, promotional merchandise companies, and online marketplaces. They serve children's hospitals seeking therapeutic comfort items, corporate clients requiring branded mascots, and seasonal retailers needing holiday-themed collections. Geographic reach capabilities allow suppliers to facilitate international trade relationships, managing customs documentation, shipping logistics, and currency exchange considerations. Product customization services enable clients to specify unique designs, materials, and branding requirements. Many suppliers maintain relationships with multiple manufacturing facilities, ensuring production capacity flexibility and risk mitigation. Digital catalog management systems provide clients with comprehensive product information, pricing structures, and availability status. The supplier ecosystem includes warehouse facilities strategically located for optimal distribution efficiency, customer service teams providing technical support, and quality control departments ensuring product compliance before shipment.