custom plush toy manufacturers

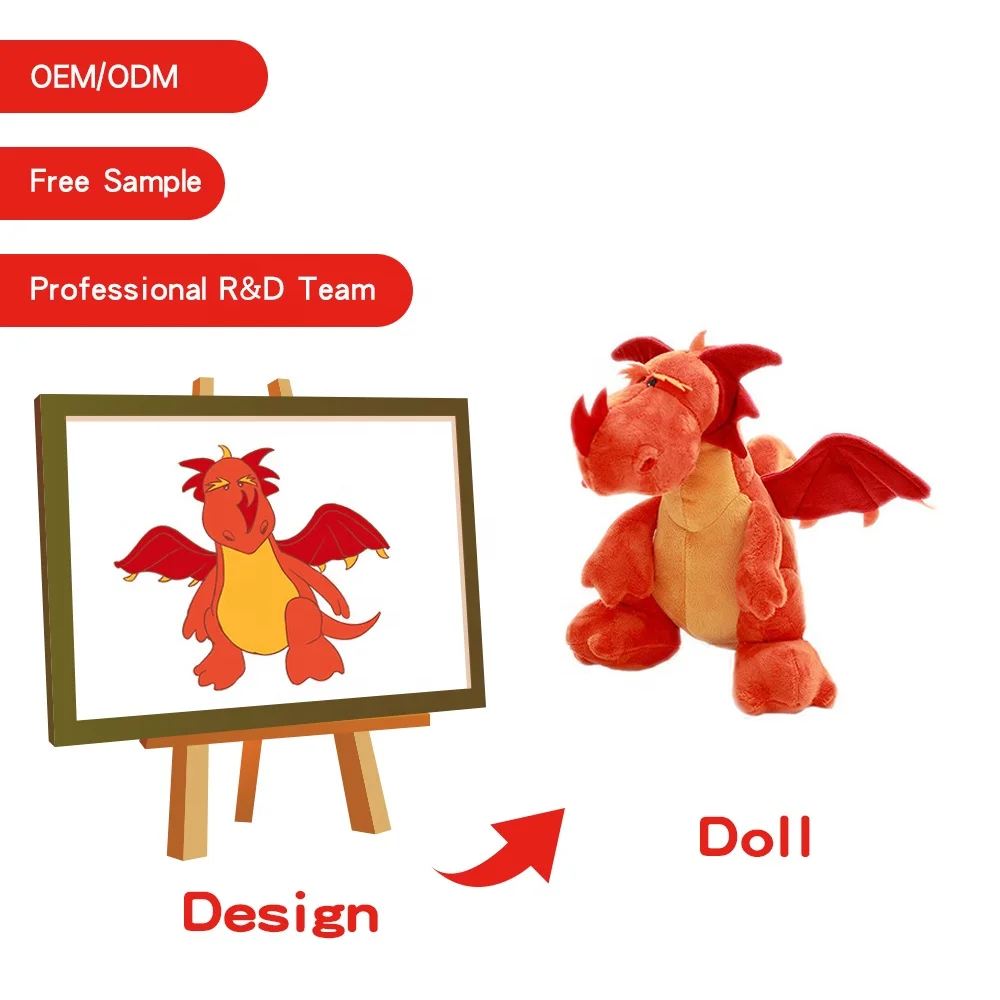

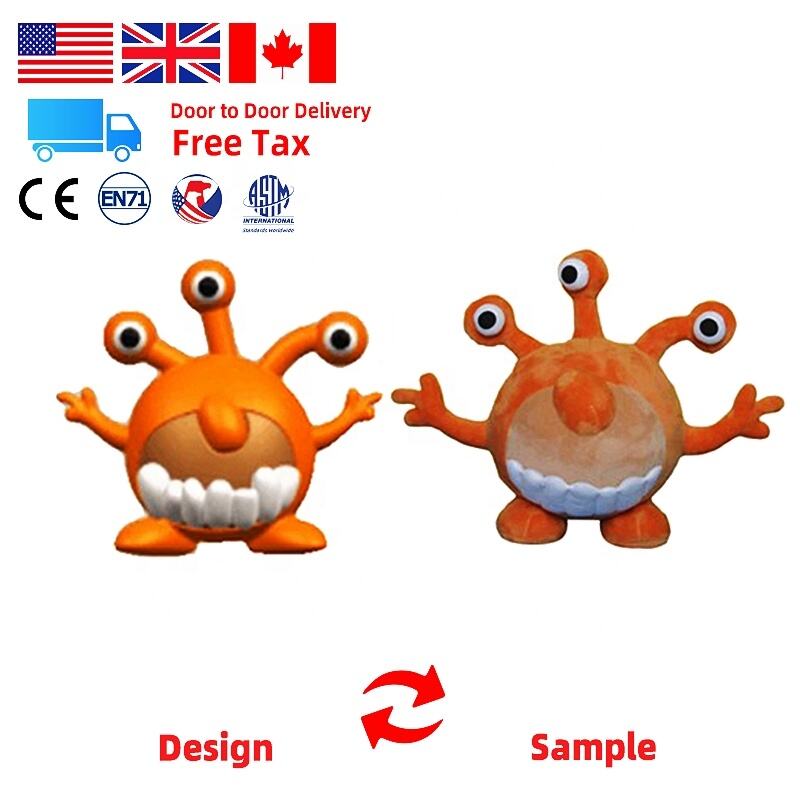

Custom plush toy manufacturers represent a specialized segment of the global toy industry, offering personalized soft toy production services that cater to diverse client requirements. These manufacturers combine traditional craftsmanship with modern production techniques to create unique, high-quality plush products tailored to specific designs, specifications, and branding needs. The primary function of custom plush toy manufacturers involves transforming conceptual ideas, artwork, or prototypes into tangible soft toys through comprehensive design-to-production processes. Their technological infrastructure encompasses computer-aided design systems, precision cutting equipment, automated stitching machinery, and quality control mechanisms that ensure consistent product standards. Advanced manufacturers utilize digital pattern-making software, 3D modeling capabilities, and prototype development technologies to streamline the customization process. The production workflow typically includes design consultation, material selection, sample creation, approval processes, bulk manufacturing, and quality assurance testing. Modern custom plush toy manufacturers serve multiple market segments including corporate promotional campaigns, entertainment licensing, educational institutions, retail brands, fundraising organizations, and individual consumers seeking personalized gifts. Their applications extend beyond traditional toy markets into therapeutic settings where custom comfort items support emotional well-being, mascot development for sports teams and businesses, collectible merchandise for entertainment properties, and branded promotional materials for marketing campaigns. The manufacturing process involves specialized techniques such as embroidery, screen printing, heat transfer applications, and multi-material integration to achieve desired aesthetic and functional outcomes. Quality control measures include safety testing compliance with international standards, durability assessments, and material verification protocols. These manufacturers typically maintain certifications for toy safety regulations including CPSIA, CE marking, and ASTM standards, ensuring products meet global market requirements for children's toys and promotional items across various international markets.