plush doll manufacturers

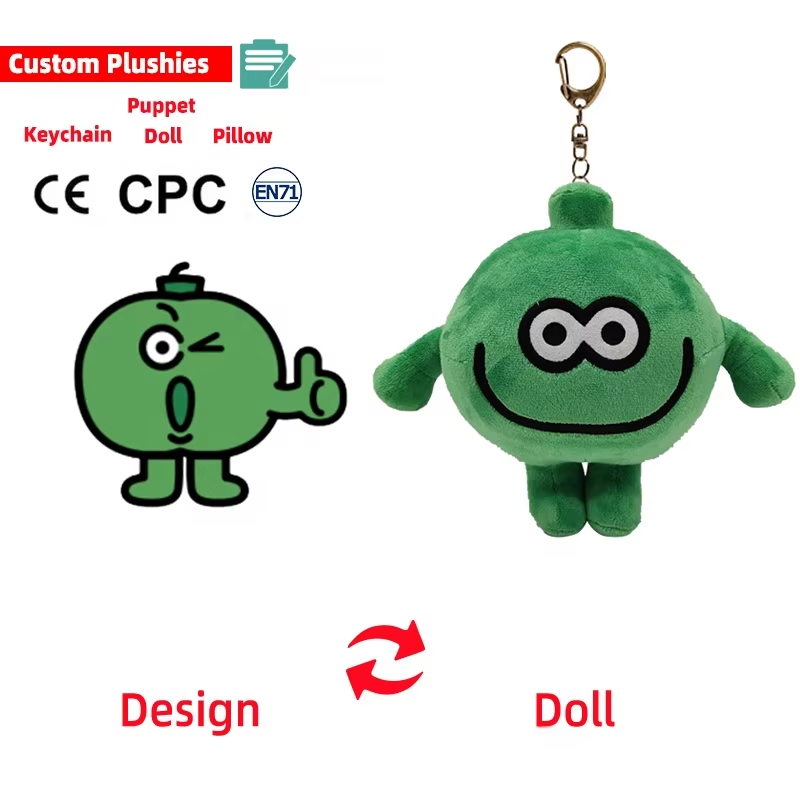

Plush doll manufacturers represent a specialized sector within the global toy and collectibles industry, focusing on the design, production, and distribution of soft-bodied figurines that appeal to consumers across all age demographics. These manufacturing enterprises combine traditional craftsmanship with modern production technologies to create high-quality stuffed toys, character collectibles, and promotional merchandise. The primary functions of plush doll manufacturers encompass conceptual design development, material sourcing, pattern creation, cutting and sewing operations, stuffing procedures, quality control testing, and final packaging processes. Contemporary plush doll manufacturers utilize advanced technological features including computer-aided design software for pattern optimization, automated cutting machinery for precision fabric preparation, programmable sewing equipment for consistent stitching quality, and specialized filling systems that ensure uniform density distribution throughout each product. Digital embroidery machines enable intricate detailing and custom branding options, while heat-pressing technology allows for durable logo application and character face creation. Quality assurance systems incorporate material testing protocols, safety compliance verification, and batch tracking mechanisms to maintain production standards. The applications for products from plush doll manufacturers span numerous markets including retail toy stores, promotional marketing campaigns, entertainment licensing partnerships, educational institutions, healthcare facilities, and direct-to-consumer e-commerce platforms. These manufacturers serve diverse client needs ranging from small boutique orders to large-scale commercial contracts, providing custom character development, licensed property reproduction, and private label manufacturing services. Modern plush doll manufacturers increasingly focus on sustainable production practices, incorporating eco-friendly materials, reducing waste through efficient cutting patterns, and implementing energy-efficient manufacturing processes. The integration of digital technologies enables real-time production monitoring, inventory management, and quality tracking systems that enhance operational efficiency and customer satisfaction levels throughout the manufacturing pipeline.